Slow decarbonization-nanofiltration combined softening treatment system and method for circulating cooling water of thermal power plant

A technology of circulating cooling water and slow decarbonization. It is used in natural water treatment, descaling and water softening, water/sewage treatment, etc. It can solve the problem of frequent reverse osmosis cleaning, ultrafiltration fouling, frequent and other problems, to achieve the effect of alleviating organic pollution and microbial pollution, reducing the amount of waste water, and reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

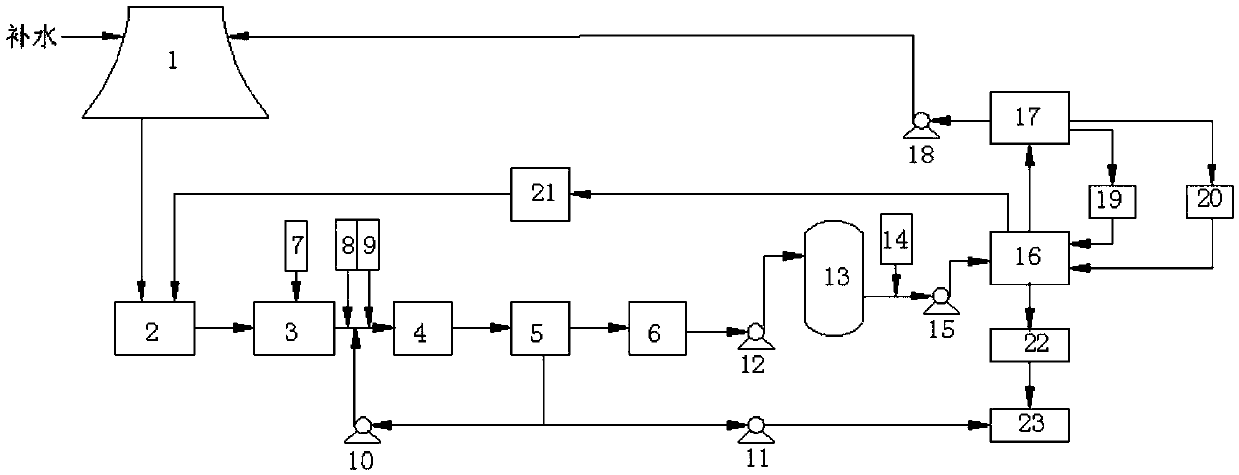

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] refer to figure 1 , the thermal power plant circulating cooling water slow decarburization-nanofiltration combined softening treatment system includes a circulating water cooling tower 1, a raw water pool 2, a desulfurization absorption tower 23, a nanofiltration system and a slow decarburization system; The slow decarbonization system includes coagulation tank 3, flocculation tank 4, high-efficiency clarification tank 5, coagulant storage tank 7, lime milk storage tank 8 and coagulant aid storage tank 9;

[0028] The circulating water discharge sewage outlet of the circulating water cooling tower 1 is connected with the water inlet of the raw water tank 2, the water outlet of the raw water tank 2 is connected with the water inlet of the coagulation tank 3, and the water outlet of the coagulation tank 3 is connected with the bottom of the flocculation tank 4 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com