Grafting reaction method and device

A grafting reaction and short-chain technology, applied in the field of grafting reaction methods and devices thereof, can solve the problems of incapable of mass industrial production, small addition amount, limited effect, etc. Low cross-linking possibility and small size of cross-linked product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

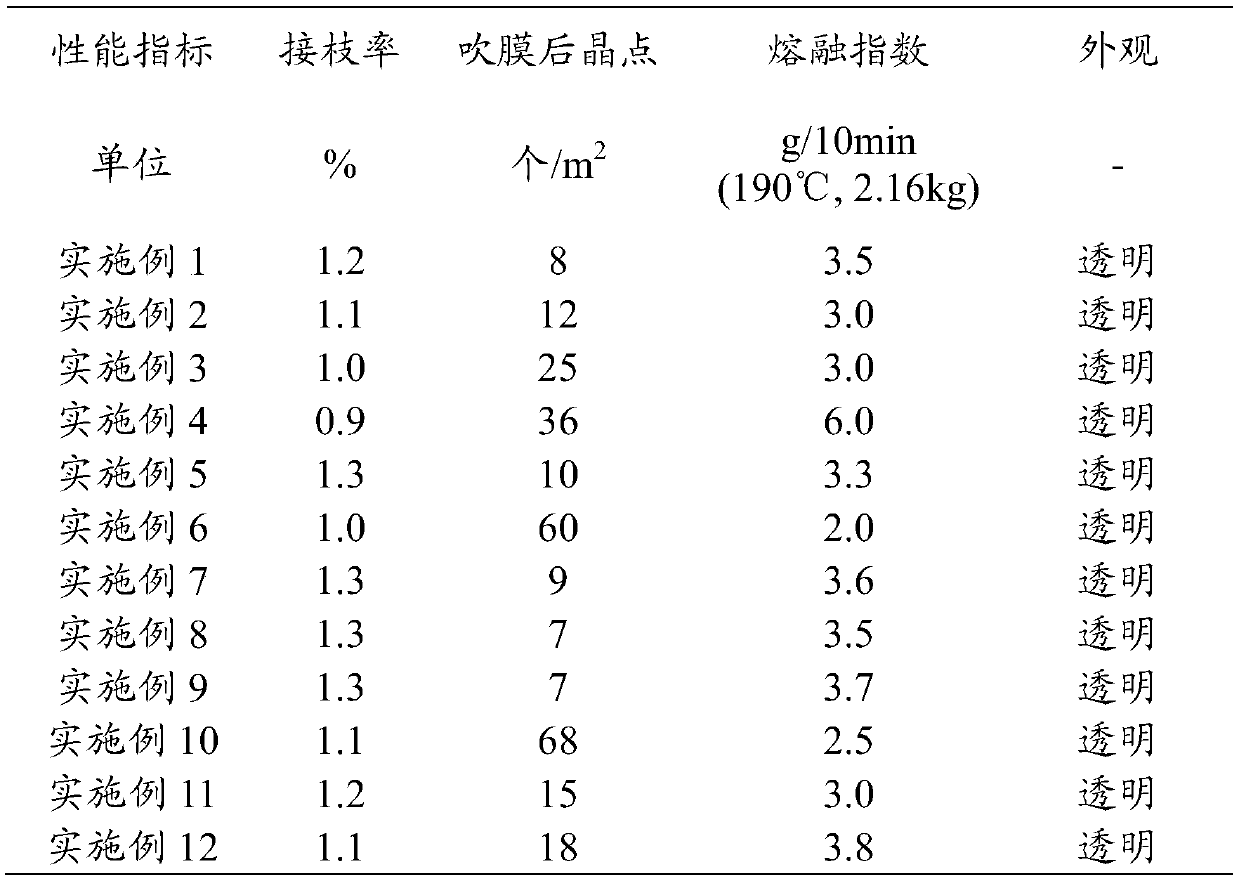

Examples

preparation example Construction

[0032] 2) Preparation of short-chain free radicals: Extruding polyolefin through twin-screws, wherein the extrusion temperature is 200-350°C, and the rotation speed is 500-1000rpm, to obtain short-chain free radicals;

[0033] The polyolefin is preferably a blend of polyethylene and polypropylene;

[0034] 3) Side feeding: Add the premixed material obtained in step 1) to the feeding end of the twin-screw extruder, and feed the short-chain free compound obtained in step 2) into the middle and rear section of the heating zone of the twin-screw extruder. The graft polymer is obtained by extrusion, wherein the extrusion temperature is 130-250°C, and the rotation speed is 300-500rpm;

[0035] Both the feeding methods of the first screw extruder and the second screw extruder adopt weightless feeding control, and the ratio of the feeding speed of the first extruder to the feeding speed of the second extruder is 4-9:1.

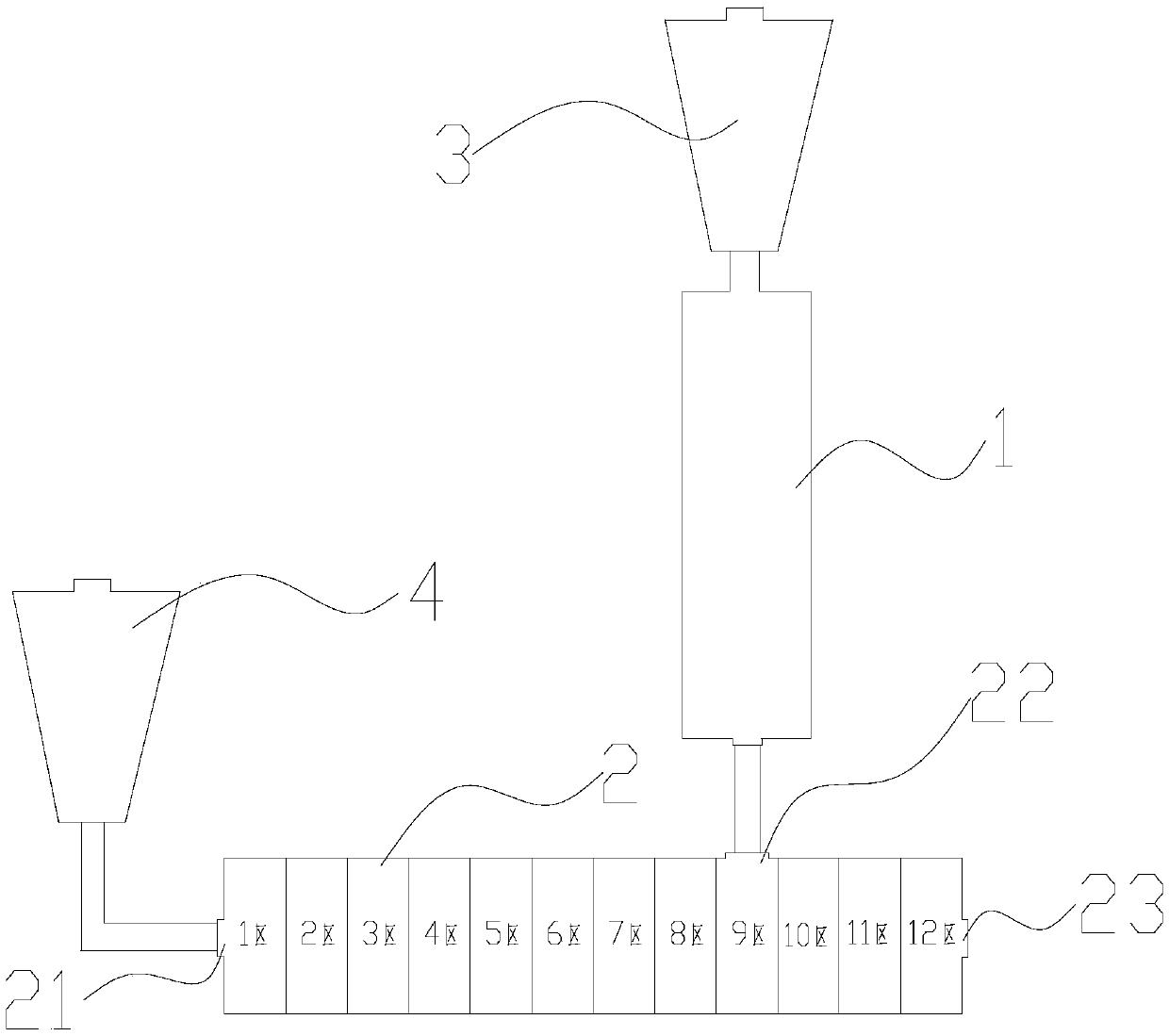

[0036] The present invention provides the device of above-menti...

Embodiment 1

[0041] A grafting reaction method, comprising the following steps:

[0042] 1) Premixing: Put 88kg of linear low density polyethylene (LLDPE for short) with a melt index of 4g / 10min (190°C, 2.16kg), 0.3kg of dicumyl peroxide, 1.5kg of maleic anhydride and 0.2kg of solvent oil into the High mixer premixing to obtain premixed material;

[0043] 2) Preparation of short-chain free radicals: Feed 5 kg of high-density polyethylene (referred to as HDPE) with a melt index of 6 g / 10 min (190 ° C, 2.16 kg) to the feeding end of the first twin-screw extruder through the first loss-in-weight feeding device. ), 3kg of a mixture of copolymerized polypropylene (referred to as co-PP) with a melt index of 8g / 10min (230°C, 2.16kg) and 2kg of polyolefin elastomer (referred to as POE) with a melt index of 5g / 10min (190°C, 2.16kg) , through extrusion, to obtain short-chain free radicals;

[0044] Among them, the length-to-diameter ratio of the first twin-screw extruder is 28:1, the screw diamete...

Embodiment 2

[0048] A grafting reaction method, comprising the following steps:

[0049] 1) Premixing: Put 88kg of linear low density polyethylene (LLDPE for short) with a melt index of 4g / 10min (190°C, 2.16kg), 0.3kg of dicumyl peroxide, 1.5kg of maleic anhydride and 0.2kg of solvent oil into the High mixer premixing to obtain premixed material;

[0050] 2) Preparation of short-chain free radicals: Feed 5 kg of high-density polyethylene (referred to as HDPE) with a melt index of 6 g / 10 min (190 ° C, 2.16 kg) to the feeding end of the first twin-screw extruder through the first loss-in-weight feeding device. ), 3kg of a mixture of copolymerized polypropylene (referred to as co-PP) with a melt index of 8g / 10min (230°C, 2.16kg) and 2kg of polyolefin elastomer (referred to as POE) with a melt index of 5g / 10min (190°C, 2.16kg) , through extrusion, to obtain short-chain free radicals;

[0051] Among them, the length-to-diameter ratio of the first twin-screw extruder is 28:1, the screw diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com