Rubber material for submerged cots used in plating tank of electrogalvanizing unit and method for manufacturing the cots

An electro-galvanizing and unit technology, which is applied to the rubber material for the submerged rubber roller of the electro-galvanizing unit's plating tank and the manufacturing field of the rubber roller, can solve the problems affecting the surface quality of the steel plate and the production efficiency of the unit, and achieve excellent resistance to The performance of hot plating solution, the degree of vulcanization are uniform and the effect of good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

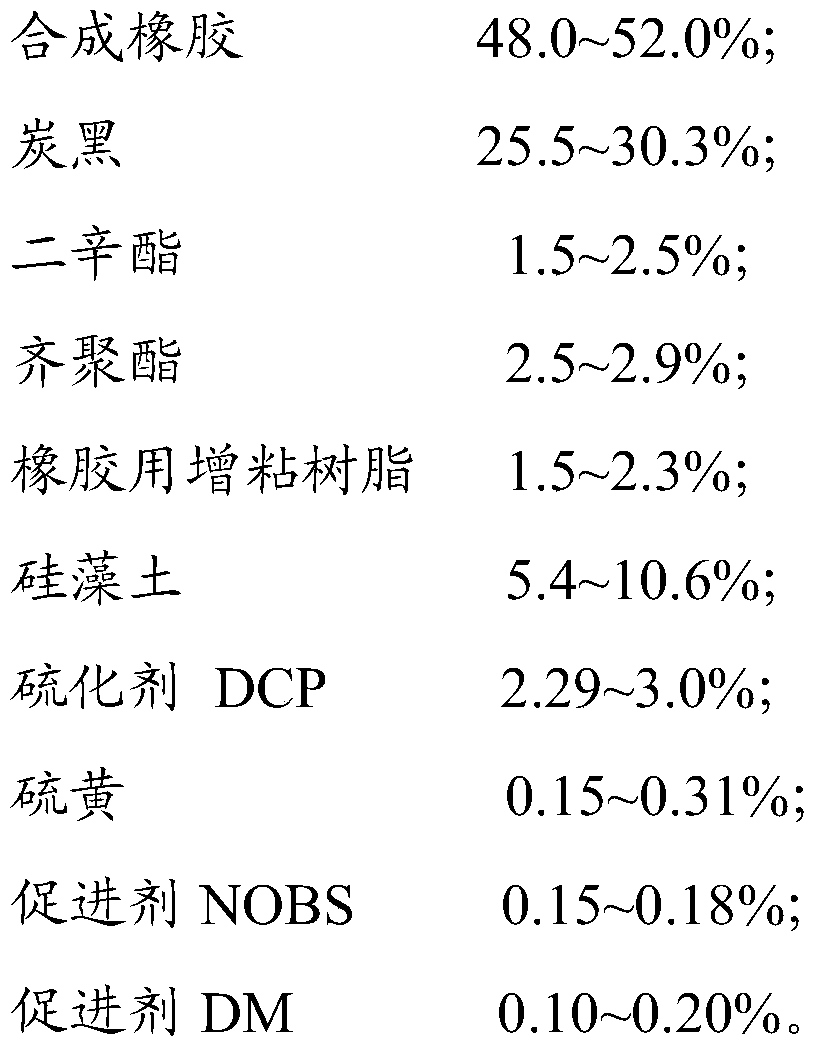

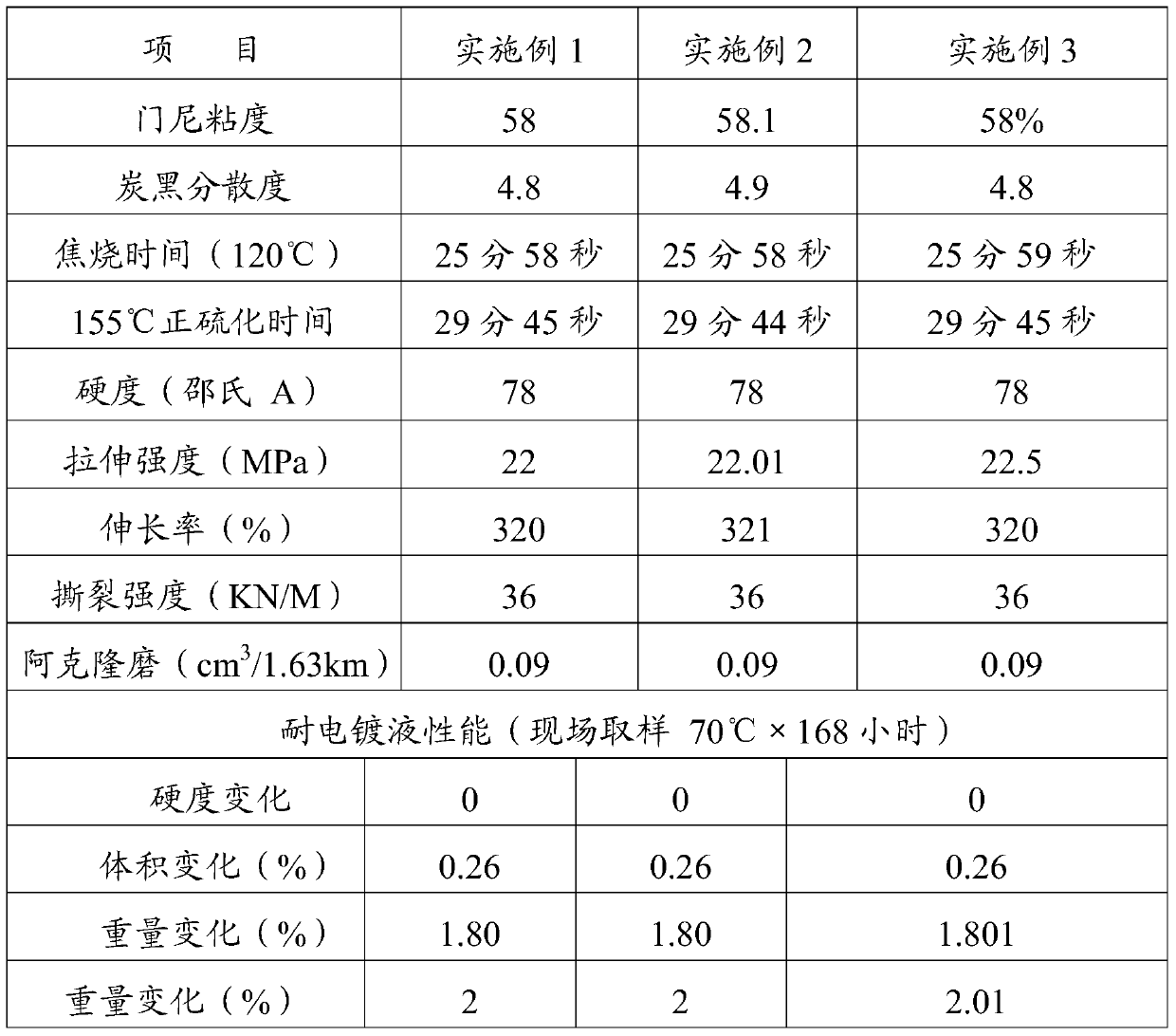

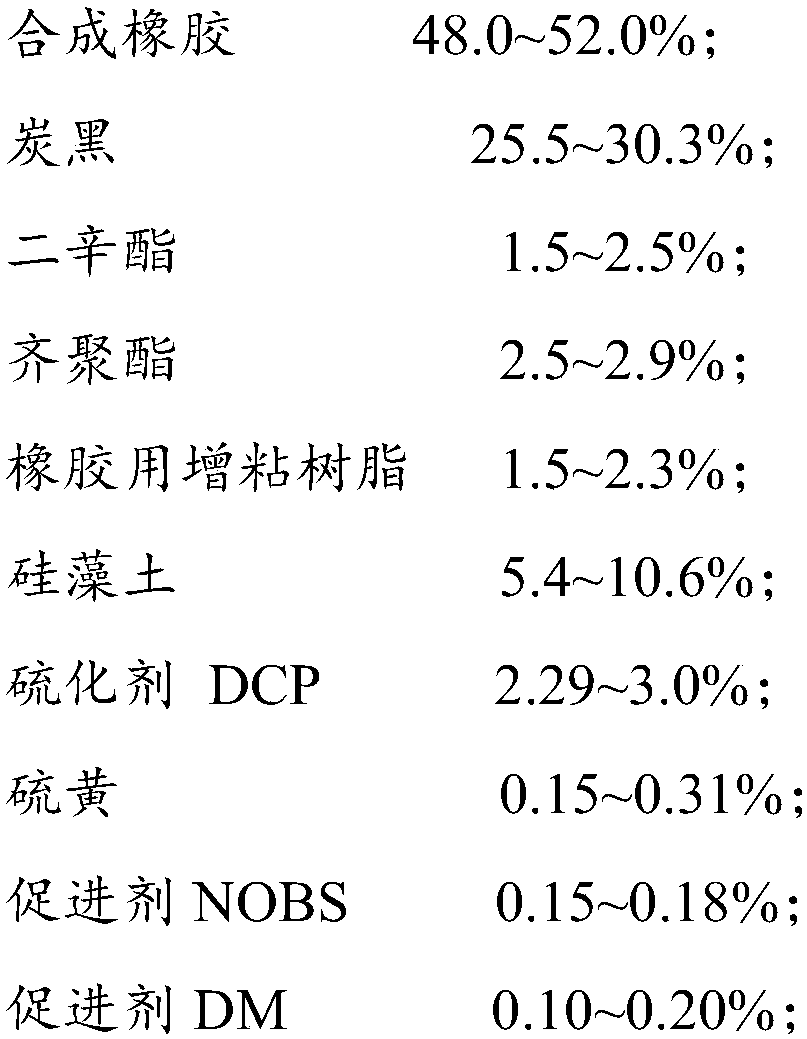

Embodiment 1

[0028] 1. According to the formula and ingredients in Table 1, put Hyperon rubber in an internal mixer, masticate at 30-40°C for 70s, then add tackifier, carbon black and diatomaceous earth, Mix at ℃ for 50s, then add dioctyl ester and oligoester, banbury at 90-100℃ for 100s, lift the plug, and after 125s, discharge at 115℃ to obtain the mixing masterbatch;

[0029] 2. Park the mixed masterbatch for 24 hours, then add sulfur in the second stage, place the parked masterbatch on the roller of the open mill, and add sulfur, accelerator NOBS, and accelerator after the surface of the masterbatch roll is smooth and flat. Agent DM, vulcanizing agent DCP, after all the above components are mixed into the masterbatch, it is turned over with a knife, and the rubber material is made into 2 triangle bags and 3 rolls, and then strips are ready for use;

[0030] 3. Winding and encapsulation: first preheat the temperature of the screw extruder barrel, screw and machine head equipment to 50°C...

Embodiment 2

[0035] 1. According to the formula and ingredients in Table 1, put Hyperon rubber in an internal mixer, masticate at 30-40°C for 70s, then add tackifier, carbon black and diatomaceous earth, Mix at ℃ for 50s, then add dioctyl ester and oligoester, banbury at 90-100℃ for 100s, lift the plug, and after 125s, discharge at 115℃ to obtain the mixing masterbatch;

[0036] 2. Park the mixed masterbatch for 24 hours, then add sulfur in the second stage, place the parked masterbatch on the roller of the open mill, and add sulfur, accelerator NOBS, and accelerator after the surface of the masterbatch roll is smooth and flat. Agent DM, vulcanizing agent DCP, after all the above components are mixed into the masterbatch, it is turned over with a knife, and the rubber material is made into 2 triangle bags and 3 rolls, and then strips are ready for use;

[0037] 4. Winding and encapsulation: first preheat the temperature of the screw extruder barrel, screw and head equipment to 50°C, 60°C a...

Embodiment 3

[0042] 1. According to the formula and ingredients in Table 1, put Hyperon rubber in an internal mixer, masticate at 30-40°C for 70s, then add tackifier, carbon black and diatomaceous earth, Mix at ℃ for 50s, then add dioctyl ester and oligoester, banbury at 90-100℃ for 100s, lift the plug, and after 125s, discharge at 115℃ to obtain the mixing masterbatch;

[0043] 2. Park the mixed masterbatch for 24 hours, then add sulfur in the second stage, place the parked masterbatch on the roller of the open mill, and add sulfur, accelerator NOBS, and accelerator after the surface of the masterbatch roll is smooth and flat. Agent DM, vulcanizing agent DCP, after all the above components are mixed into the masterbatch, it is turned over with a knife, and the rubber material is made into 2 triangle bags and 3 rolls, and then strips are ready for use;

[0044] 3. Winding and encapsulation: first preheat the temperature of the screw extruder barrel, screw and machine head equipment to 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com