Fluoroboric acid blocking remover and acidification de-blocking method

A technology of fluoroboric acid and blocking agent, applied in the field of oil and gas exploration, can solve problems such as the inability to effectively deal with the water lock effect of pore blockage, and achieve the effects of releasing the water lock effect, high corrosion rate, and slowing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

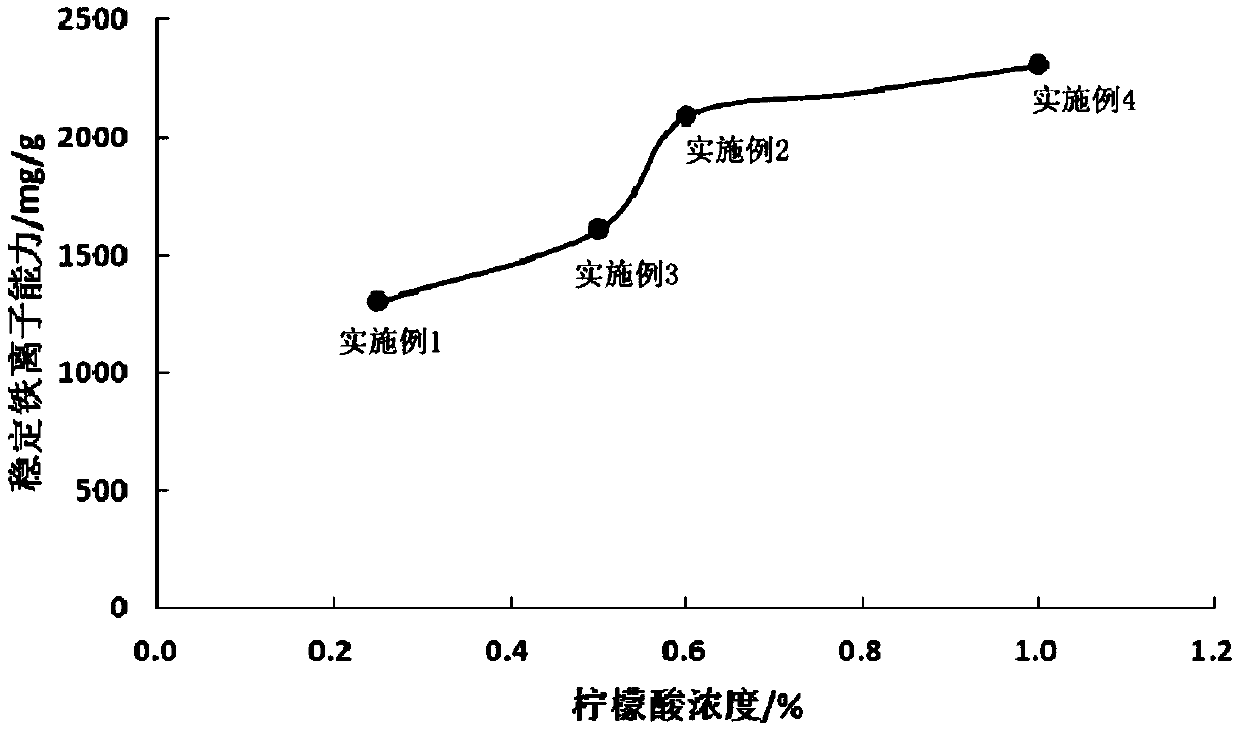

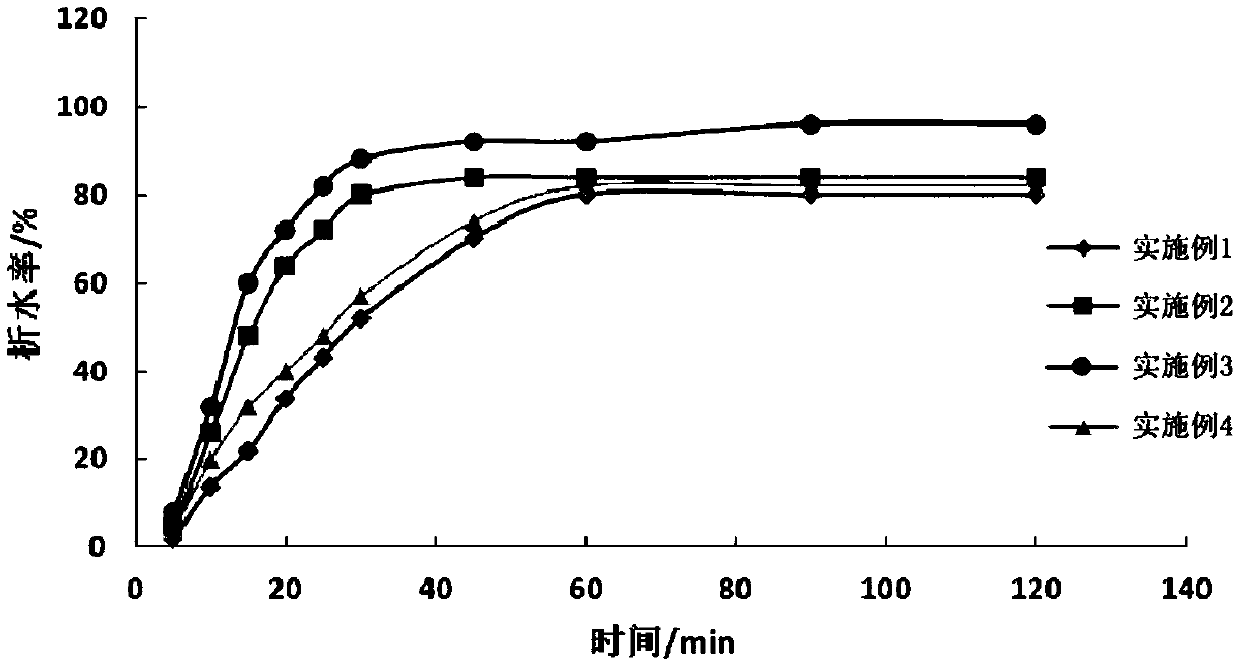

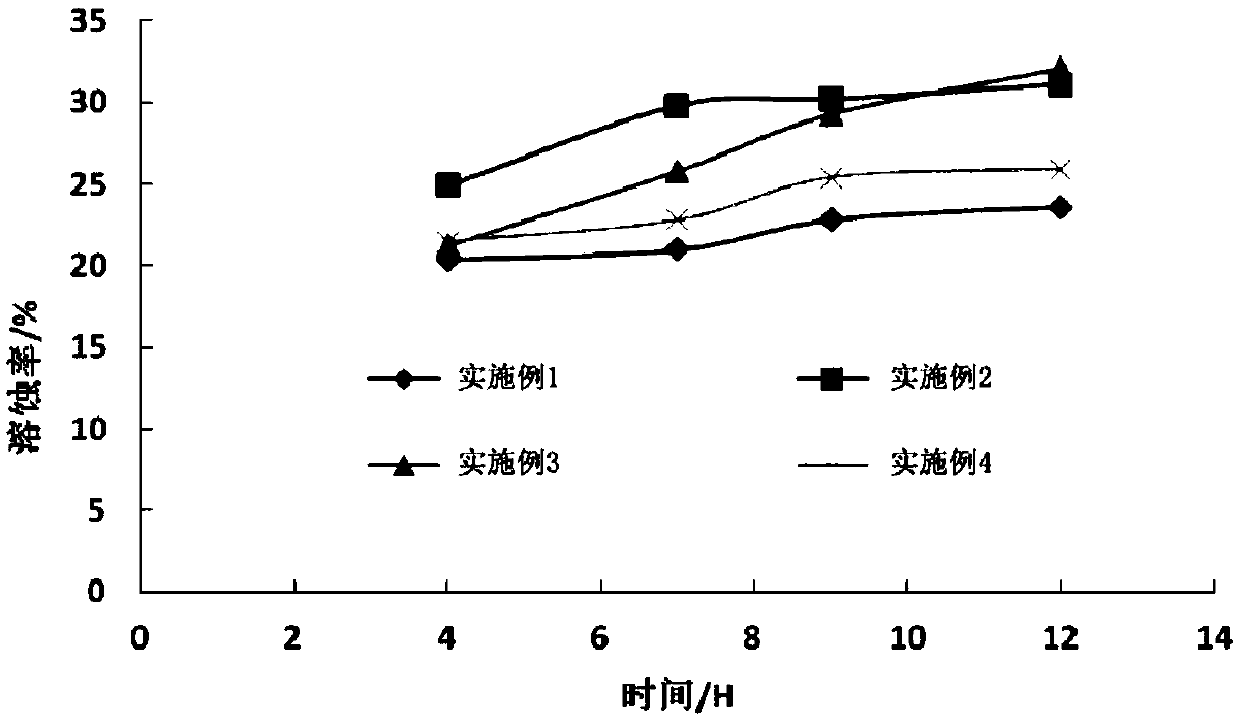

[0040] The fluoboric acid plugging remover for decontaminating oil and gas reservoirs in this embodiment consists of pre-acid, main acid and post-acid; the pre-acid and post-acid are the same, and are composed of the following components in mass percentage: hydrochloric acid 10%, 0.8% clay stabilizer, 0.25% iron ion stabilizer, 0.25% corrosion inhibitor, 0.4% hydrolytic locking agent, 0.2% mutual solvent, and the balance is water;

[0041] The main acid is composed of the following components in mass percentage: 6% acetic acid, 2% fluoboric acid, 0.8% clay stabilizer, 0.25% iron ion stabilizer, 0.25% corrosion inhibitor, 0.4% hydrolytic lock agent, 0.2% mutual solvent, The balance is water.

[0042] The clay stabilizer is ammonium chloride, the iron ion stabilizer is citric acid, the corrosion inhibitor is SJ-21 normal temperature acidification corrosion inhibitor, the water lock agent is AS-3 water lock damage treatment agent, and the mutual solvent is ethylene glycol butyl ...

Embodiment 2

[0045] The fluoboric acid plugging remover for decontaminating oil and gas reservoirs in this embodiment consists of pre-acid, main acid and post-acid; the pre-acid and post-acid are the same, and are composed of the following components in mass percentage: hydrochloric acid 10%, 1% clay stabilizer, 0.6% iron ion stabilizer, 0.5% corrosion inhibitor, 0.6% hydrolytic lock agent, 0.8% mutual solvent, and the balance is water;

[0046] The main acid is composed of the following components in mass percentage: 6% acetic acid, 2% fluoboric acid, 1% clay stabilizer, 0.6% iron ion stabilizer, 0.5% corrosion inhibitor, 0.6% hydrolytic lock agent, 0.8% mutual solvent, The balance is water; the clay stabilizer is ammonium chloride, the iron ion stabilizer is citric acid, the corrosion inhibitor is SJ-21 normal temperature acidification corrosion inhibitor, and the dehydration lock agent is AS-3 water lock damage treatment agent, mutual solvent For ethylene glycol butyl ether.

[0047] T...

Embodiment 3

[0049] The fluoboric acid plugging agent of this embodiment is composed of a pre-acid, a main acid and a post-acid; the pre-acid and post-acid are the same and are composed of the following components in mass percentages: hydrochloric acid 10%, clay stabilizer 1% , 0.5% of iron ion stabilizer, 0.5% of corrosion inhibitor, 0.5% of hydrolytic lock agent, 0.5% of mutual solvent, and the balance is water;

[0050] The main acid is composed of the following components in mass percentage: 6% acetic acid, 2% fluoboric acid, 1% clay stabilizer, 0.5% iron ion stabilizer, 0.5% corrosion inhibitor, 0.5% hydrolytic lock agent, 0.5% mutual solvent, The balance is water; the clay stabilizer is ammonium chloride, the iron ion stabilizer is citric acid, the corrosion inhibitor is SJ-21 normal temperature acidification corrosion inhibitor, and the dehydration lock agent is AS-3 water lock damage treatment agent, mutual solvent For ethylene glycol butyl ether.

[0051] The acidification pluggi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com