Device and method for realizing thick silver film as surface reinforced Raman scattering substrate by physical method

A surface-enhanced Raman and physical method technology, applied in Raman scattering, measuring devices, sputtering coating, etc., can solve the problems of insufficient enhancement effect and harsh preparation conditions, and achieve strong enhancement effect and convenient preparation technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

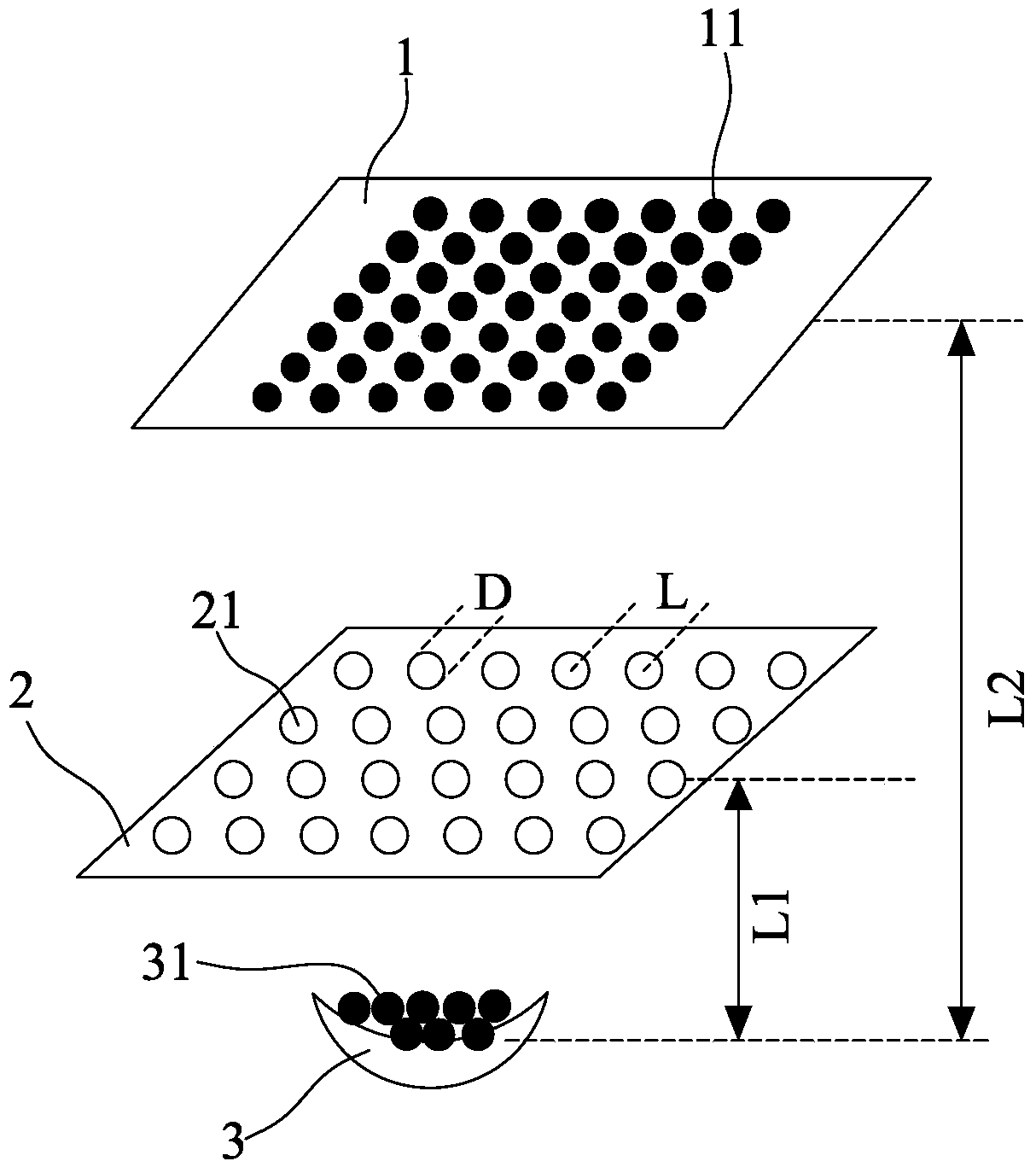

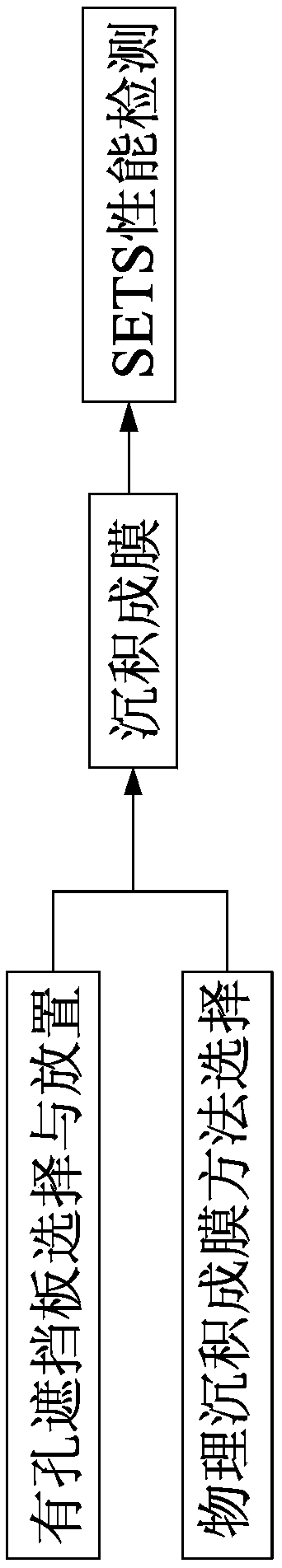

[0048] Deposition equipment: On the resistance evaporation coating equipment, a plate with uniform round holes is used as a shielding plate to realize the SERS enhancement effect of a 350nm thick silver film. The specific test and detection parameters are as follows:

[0049] Shading plate parameters: plate size: 20×40mm 2 , hole diameter: 2mm, hole spacing: 10mm, shielding plate placement method: placed in parallel at a distance of 5cm directly above the evaporation source, and a vertical distance of 20cm from the substrate table;

[0050] Deposition and film formation parameters: raw material: 99.99% pure silver, evaporation boat size: 100×10mm 2 , Substrate: k9 glass, substrate temperature: room temperature, evaporation vacuum: 5×10 -3 pa, evaporation current: 120A, evaporation rate: 1.5nm / s; film thickness: 350nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com