Preparation method of sandwich type anti-felting double-faced woolen cloth

An anti-felting, double-sided woolen technology, applied in the field of fabrics, can solve problems such as fiber structure relaxation, and achieve the effects of soft luster, good warmth retention and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

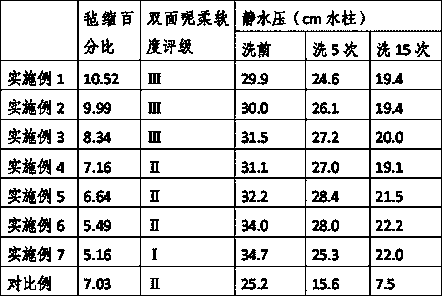

Examples

Embodiment 1

[0028] The preparation method of the sandwich type anti-felting double-faced fabric of embodiment 1 comprises the steps:

[0029] S1: Scratch-coat chitosan acid solution on the A side of the inner wool fabric, the concentration of chitosan in the chitosan acid solution is 2%, dry naturally, wash and dry, and place the wool fabric in a low-temperature atmosphere for plasma deal with;

[0030] S2: Configure chitosan silica sol finishing solution. The main components of chitosan silica sol finishing solution are chitosan, silicon dioxide, organic polyacids, water, and the pH of chitosan silica sol finishing solution is 5. The percentage by weight of chitosan in the polysaccharide silica sol finishing solution is 0.5%, and the silicon content of the chitosan silica sol finishing solution is 2%;

[0031] S3: Soak the B side of the inner wool fabric with water spray, apply the chitosan silica sol finishing solution obtained in S2 on the wetted surface of the inner wool fabric and s...

Embodiment 2

[0038] Embodiment 2 is based on embodiment 1, difference is: the chitosan concentration in the chitosan acid solution is 5%; The weight percentage is 3%, and the silicon content of chitosan silica sol finishing liquid is 0.4%.

[0039] In the medium and low temperature plasma treatment process of S1, the non-polymerizable gas in the chamber of the plasma treatment device is argon, the applied voltage discharge frequency is 13.75MHz, the power is 200W, and the treatment time is 20s.

[0040] The preparation process of chitosan silica sol finishing solution in S2 is: dissolving chitosan in the chitosan mixed solution in the organic acid aqueous solution, adding water to the water glass to dilute, then adding the chitosan mixed solution to the water glass under stirring In the solution, adjust the pH value with an organic acid, and oscillate ultrasonically for 20 minutes; the organic acid is itaconic acid; the coating method in S3 is transfer coating.

Embodiment 3

[0042] Embodiment 3 is based on embodiment 2, difference is: the concentration of chitosan in the chitosan acid solution is 3.5%; The weight percent is 1.7%, and the silicon content of chitosan silica sol finishing liquid is 1.2%.

[0043] In the medium and low temperature plasma treatment process of S1, the non-polymerizable gas in the chamber of the plasma treatment device is ammonia gas, the applied voltage discharge frequency is 13.75MHz, the power is 100W, and the treatment time is 100s.

[0044] The preparation process of chitosan silica sol finishing solution in S2 is: dissolving chitosan in the chitosan mixed solution in the organic acid aqueous solution, adding water to the water glass to dilute, then adding the chitosan mixed solution to the water glass under stirring In the solution, adjust the pH value with an organic acid, and oscillate ultrasonically for 5 minutes; the organic acid is citric acid; the coating method in S3 is transfer coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com