Low-voltage transparent oxide thin film transistor and preparation method thereof

A transparent oxide and thin-film transistor technology, which is applied in transistors, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of inability to meet the requirements of large-screen display for process uniformity and consistency, complex p-SiTFT process, opaque LTPSTFT, etc. Problems, achieve the effect of improving device mobility, low price, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

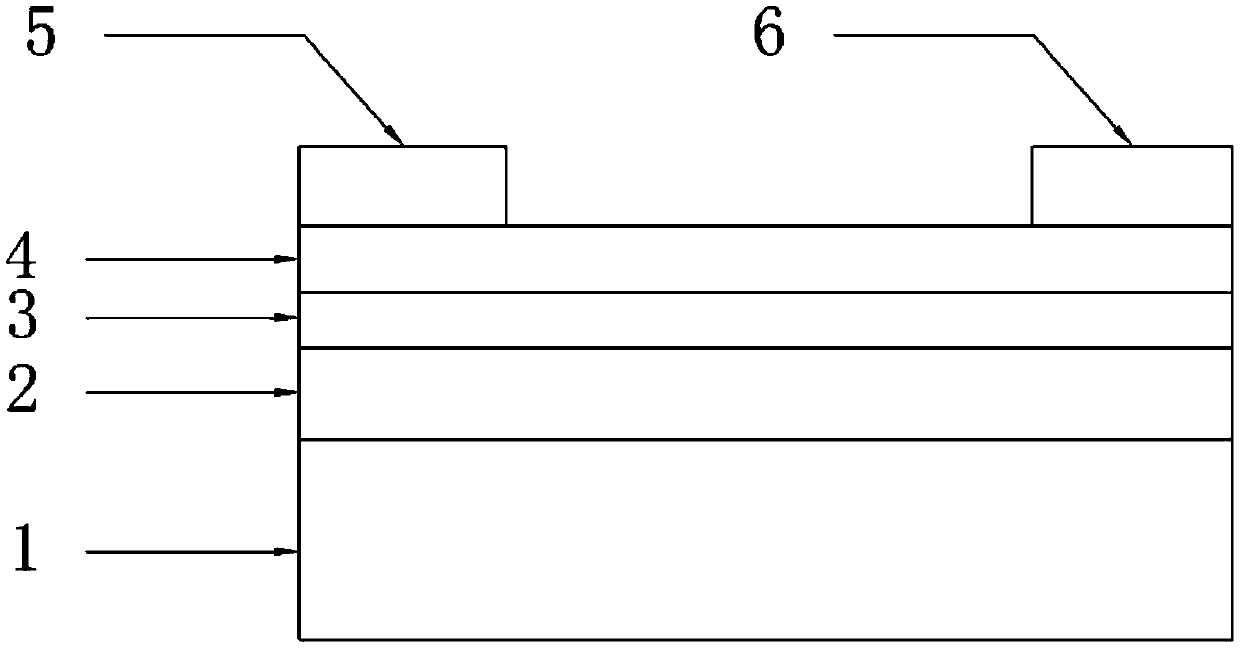

[0046] The low-voltage transparent oxide thin film transistor of this embodiment has a bottom-gate and top-electrode structure, such as figure 1 As shown, from bottom to top include:

[0047] The substrate 1 is ITO conductive glass; the upper conductive film of the ITO conductive glass is an ITO gate electrode 2;

[0048] The gate electrode insulating layer 3 is transparent ZrO 2 a film located on the ITO gate electrode 2;

[0049] The active layer 4 is a transparent oxide film located on the gate electrode insulating layer 3;

[0050] The source electrode 5 and the drain electrode 6 are both transparent tin oxide doped indium oxide (ITO) films, and are respectively located on the active layer 4 .

[0051] Wherein, the transparent oxide film is an indium-doped zinc oxide (InZnO) film; in the transparent oxide film, the mass percentage of indium is 3%; the transparent ITO (tin oxide-doped indium oxide) film Among them, the mass ratio of indium oxide to tin oxide is 90:10. ...

Embodiment 2

[0066] The low-voltage transparent oxide thin film transistor of this embodiment has a bottom-gate and top-electrode structure (the structure is the same as that of Embodiment 1), and sequentially includes from bottom to top:

[0067] The substrate is ITO conductive glass; the upper conductive film of the ITO conductive glass is an ITO grid electrode;

[0068] Gate electrode insulating layer, transparent ZrO 2 a film on the ITO gate electrode;

[0069] an active layer, which is a transparent oxide film, located on the gate electrode insulating layer;

[0070] The source electrode and the drain electrode are both transparent tin oxide doped indium oxide (ITO) films, respectively located on the active layer.

[0071] Wherein, the transparent oxide film is a titanium doped zinc oxide (TiZnO) film; in the transparent oxide film, the mass percentage of titanium is 1%; the transparent ITO (tin oxide doped indium oxide) film Among them, the mass ratio of indium oxide to tin oxide ...

Embodiment 3

[0086] The low-voltage transparent oxide thin film transistor of this embodiment has a bottom-gate and top-electrode structure (the structure is the same as that of Embodiment 1), and sequentially includes from bottom to top:

[0087] The substrate is ITO conductive glass; the upper conductive film of the ITO conductive glass is an ITO gate electrode;

[0088] Gate electrode insulating layer, transparent ZrO 2 a film on the ITO gate electrode;

[0089] an active layer, which is a transparent oxide film, located on the gate electrode insulating layer;

[0090] The source electrode and the drain electrode are both transparent tin oxide doped indium oxide (ITO) films, respectively located on the active layer.

[0091] Wherein, the transparent oxide film is gallium doped zinc oxide (GaZnO) film; in the transparent oxide film, the mass percentage of gallium is 5%; the transparent ITO (tin oxide doped indium oxide) film Among them, the mass ratio of indium oxide to tin oxide is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com