Ferroelectric/semiconductor/PMMA ternary composite resistive film with high electrical stability and preparation method thereof

A ternary composite, resistive thin film technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of the decline in yield of composite resistive memory structures, the electrical instability of organic semiconductors, and the weakening of device resistive characteristics. and other problems, to achieve the effect of improving breakdown resistance, high electrical stability, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This example illustrates the optimum PMMA doping amount.

[0017] Prepare the PMMA / P3HT / P(VDF-TrFE) composite film according to the preparation process of the ternary composite resistive film in the summary of the invention, wherein when configuring the tetrahydrofuran solution, keep the mass percentage of P(VDF-TrFE) as 3%, PMMA: The P3HT:P(VDF-TrFE) mass ratio is x:1:10, where x is a variable between 0 and 0.5.

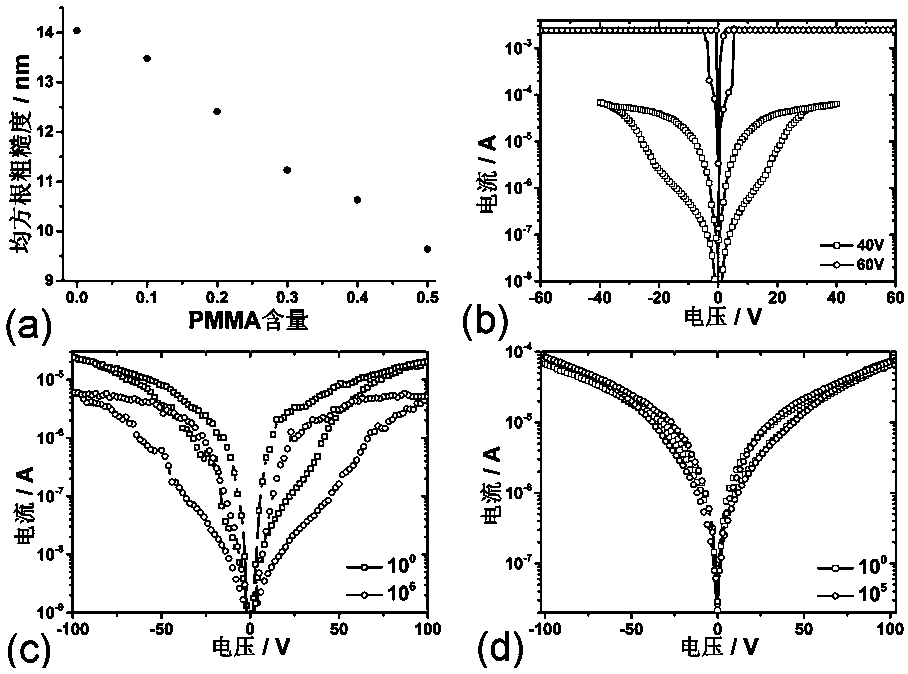

[0018] The root mean square surface roughness of the film was measured by atomic force microscope, the results are as follows figure 1 As shown in (a), it can be seen that with the increase of PMMA doping amount (x from 0 to 0.5), the surface roughness of the film is significantly reduced, which helps to reduce the leakage current of the device.

[0019] Figures (b) to (d) show the resistive characteristic curves obtained when x=0, 0.2 and 0.5 respectively. When x=0 (Figure b), when the positive and negative bias voltage amplitude is 40V, an obvious butterf...

Embodiment 2

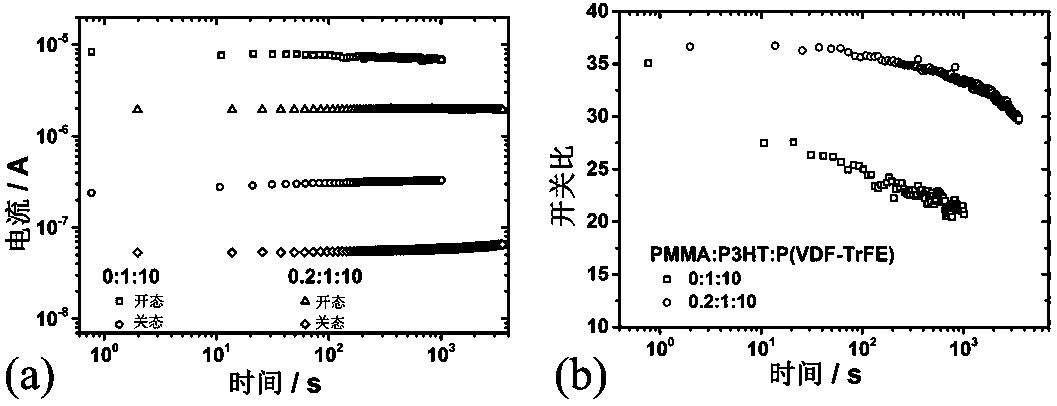

[0022] This example illustrates that after optimizing the doping amount of PMMA, the resistance state retention performance of the obtained thin film is also significantly improved.

[0023] Prepare the PMMA / P3HT / P(VDF-TrFE) composite film according to the preparation process of the ternary composite resistive film in the summary of the invention, wherein when configuring the tetrahydrofuran solution, keep the mass percentage of P(VDF-TrFE) as 3%, PMMA: The mass ratio of P3HT:P(VDF-TrFE) is x:1:10, and x is 0 (corresponding to no PMMA doping) or 0.2 (corresponding to optimized PMMA doping amount).

[0024] figure 2 (a) shows the change of on-state and off-state current with time. Compared with the case without PMMA doping (x=0), after PMMA doping (x=0.2), the leakage current of the film is effectively suppressed, The obtained on-state current and off-state current are lower than those obtained without PMMA doping. figure 2 (b) shows the ratio of the on-state current to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com