Method for high density production of bacillus amyloliquefaciens by combination of liquid and semisolid fermentation technologies

A technology of semi-solid fermentation and amylolysis spores, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemicals for biological control, etc., can solve the problems of low bacterial volume and spore rate, and achieve the production process Economical and practical, reducing the chance of pollution and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

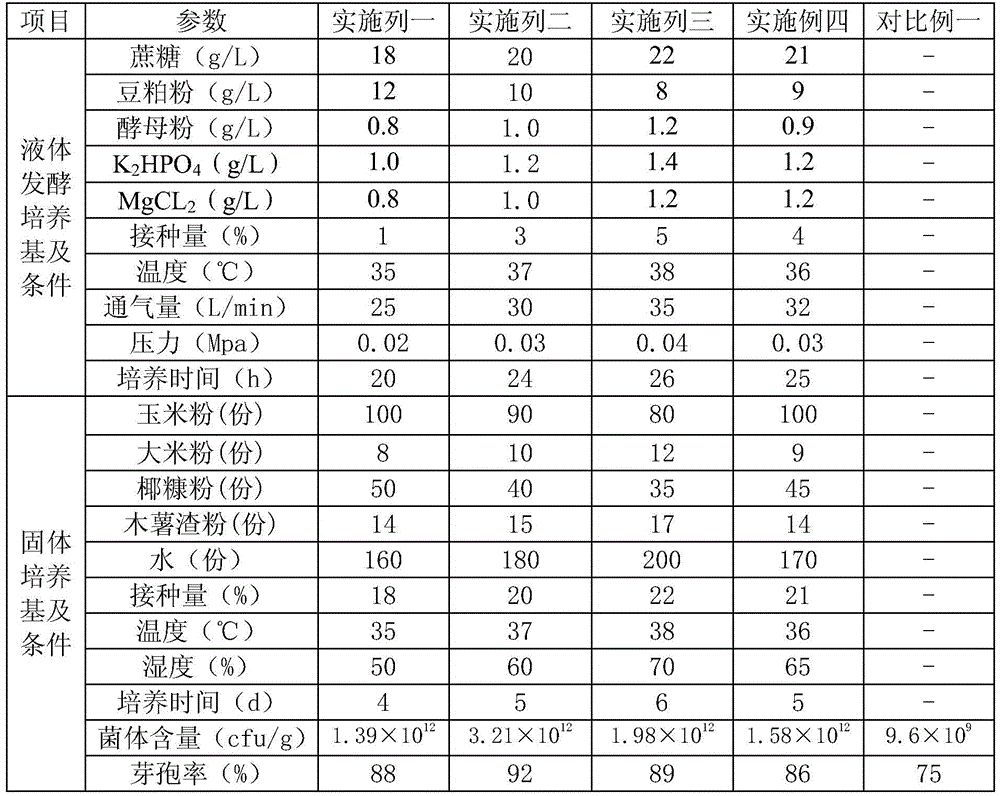

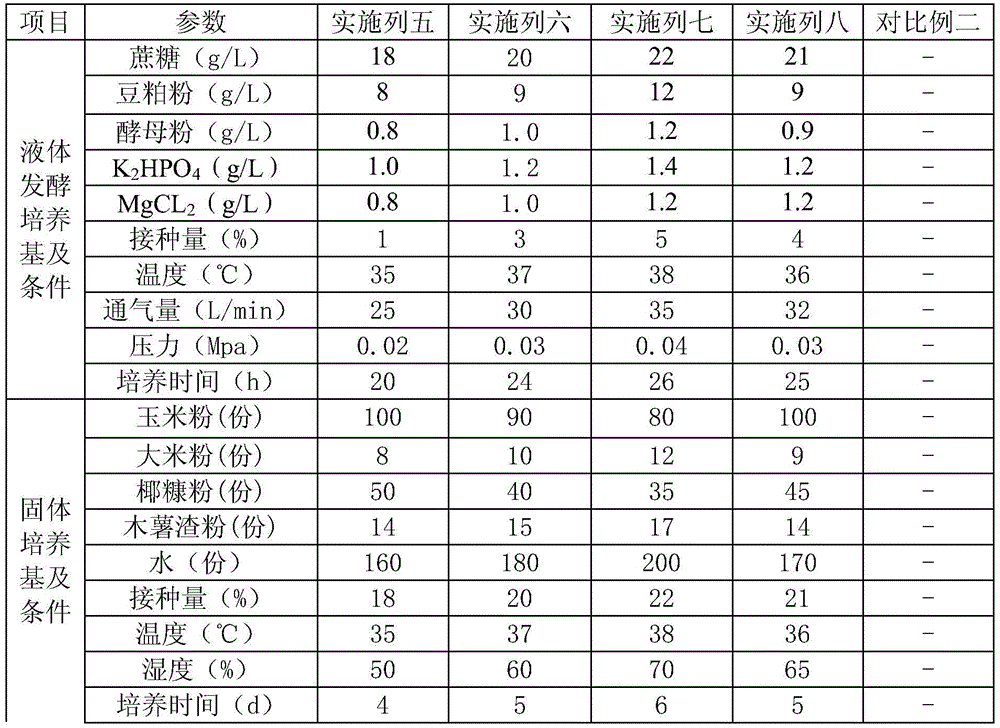

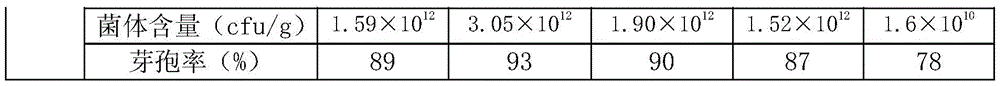

Examples

Embodiment 1

[0033] The production method of Bacillus amyloliquefaciens (Bacillus amyloliquefaciens) HC200 comprises the following steps:

[0034] 1. Bacteria culture

[0035] Bacillus amyloliquefaciens HC200 was inoculated on the LB medium plate, and cultured at 37°C for 32 hours until the bacteria covered the plate.

[0036] LB medium: tryptone 10g, yeast extract 5g, NaCl 10g, agar 17g, dilute to 1000ml with water, pH 7.0.

[0037] 2. Liquid seed culture

[0038] Fill 400ml liquid seed culture medium in the 1000ml Erlenmeyer flask, then inoculate the bacterial classification that step 1 cultivates, the inoculation amount is the culture dish flat plate bacterial classification of 1 / 6 of each Erlenmeyer flask inoculation (petri dish specification is 90mm), 37 ℃ , 180rpm cultured for 24h to obtain seed liquid, the bacterial concentration in the seed liquid was 1.2×10 10 cfu / mL.

[0039] Liquid seed medium: take 20g of sucrose, 10g of yeast powder, K 2 HPO 4 1.2g and MgCl 2 1g, dissol...

Embodiment 2

[0055] The production method of Bacillus amyloliquefaciens (Bacillus amyloliquefaciens) HC200 comprises the following steps:

[0056] 1. Bacteria culture

[0057] Bacillus amyloliquefaciens HC200 was inoculated on the LB medium plate, and cultured at 37°C for 40 hours until the bacteria covered the plate.

[0058] LB medium: tryptone 10g, yeast extract 5g, NaCl 10g, agar 17g, dilute to 1000ml with water, pH 7.0.

[0059] 2. Liquid seed culture

[0060] Fill 400ml liquid seed culture medium in the 1000ml Erlenmeyer flask, then inoculate the bacterial classification that step 1 cultivates, the inoculation amount is the culture dish flat plate bacterial classification of 1 / 6 of each Erlenmeyer flask inoculation (petri dish specification is 90mm), 37 ℃ , 180rpm cultured for 24h to obtain seed liquid, the bacterial concentration in the seed liquid was 4.0×10 10 cfu / mL.

[0061] Liquid seed medium: take 20g of sucrose, 10g of yeast powder, K 2 HPO 4 1.2g and MgCl 2 1g, dissol...

Embodiment 3

[0077] The production method of Bacillus amyloliquefaciens (Bacillus amyloliquefaciens) HC200 comprises the following steps:

[0078] 1. Bacteria culture

[0079] Bacillus amyloliquefaciens HC200 was inoculated on the LB medium plate, and cultured at 37°C for 48 hours until the bacteria covered the plate.

[0080] LB medium: tryptone 10g, yeast extract 5g, NaCl 10g, agar 17g, dilute to 1000ml with water, pH 7.0.

[0081] 2. Liquid seed culture

[0082] Fill 400ml liquid seed culture medium in the 1000ml Erlenmeyer flask, then inoculate the bacterial classification that step 1 cultivates, the inoculation amount is the culture dish flat plate bacterial classification of 1 / 6 of each Erlenmeyer flask inoculation (petri dish specification is 90mm), 37 ℃ , 180rpm culture for 24h, to obtain seed liquid, the bacterial concentration in the seed liquid is 5.0×10 10 cfu / mL.

[0083] Liquid seed medium: take 20g of sucrose, 10g of yeast powder, K 2 HPO 4 1.2g and MgCl 2 1g, dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com