Multielement metal oxide thin film based resistive random access memory and preparation method therefor

A technology of oxide film and multiple metals, applied in the field of memory, can solve the problems of high cost and low switching voltage, and achieve the effect of improving performance, low switching voltage, and stable anti-fatigue characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Clean the substrate: select polyimide (PI) as the substrate, scrub the substrate with alcohol to remove organic impurities, rinse the substrate with deionized water several times, and then dry it with ordinary nitrogen, repeat the above steps The steps are repeated until the substrate is clean and ready for use.

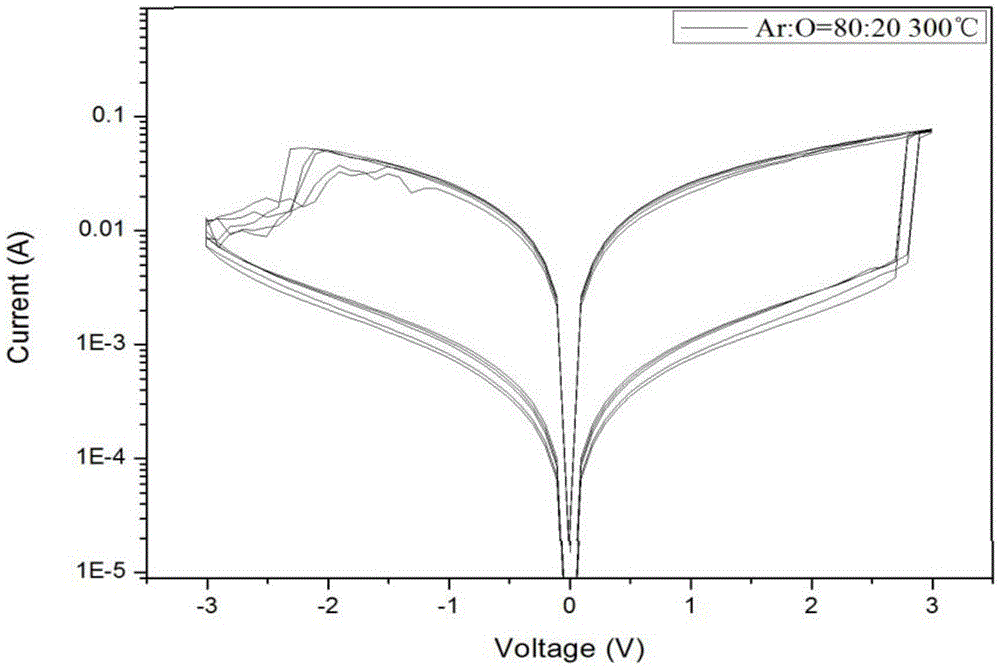

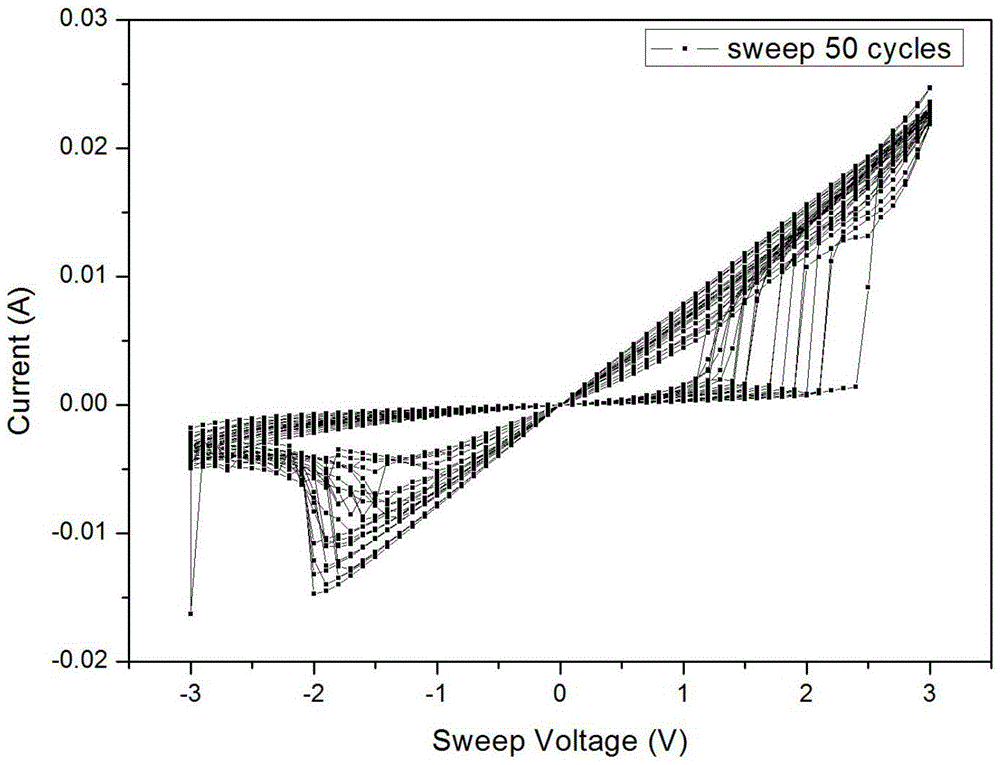

[0024] 2. Preparation of resistive memory based on CuGaZnO

[0025] 1) Prepare the bottom electrode: in the chamber of the RF magnetron sputtering coating system, select ZnO doped with 2at% Al as the target material, install it on the target stage, and place the quartz substrate on the substrate stage; The chamber is evacuated to 3.3 x 10 -3 Pa, and then flow argon gas with a flow rate of 80 sccm, set the substrate temperature at 300° C., and sputter for 2 hours at a power of 50 W to form a bottom electrode.

[0026] 2) Preparation of the resistive switch layer: take out the prepared bottom electrode substrate, and paste a mask on one side of the substrat...

Embodiment 2

[0029] 1. Clean the substrate: select polyimide (PI) as the substrate, scrub the substrate with alcohol to remove organic impurities, rinse the substrate with deionized water several times, and then dry it with ordinary nitrogen, repeat the above steps The steps are repeated until the substrate is clean and ready for use.

[0030] 2. Preparation of resistive memory based on CuGaZnO

[0031] 1) Prepare the bottom electrode: in the chamber of the RF magnetron sputtering coating system, select ZnO doped with 2at% Al as the target material, install it on the target stage, and place the quartz substrate on the substrate stage; The chamber is evacuated to 3.3 x 10 -3 Pa, and then flow argon gas with a flow rate of 80 sccm, set the substrate temperature at 100° C., and sputter for 2 hours at a power of 50 W to form a bottom electrode.

[0032] 2) Preparation of the resistive switch layer: take out the prepared bottom electrode substrate, and paste a mask on one side of the substrat...

Embodiment 3

[0035] Clean the substrate: select polyimide (PI) as the substrate, scrub the substrate with alcohol to remove organic impurities, rinse the substrate with deionized water several times, and then dry it with ordinary nitrogen, repeat the above steps for more Repeat until the substrate is clean before use.

[0036] 2. Preparation of resistive memory based on CuGaZnO

[0037] 1) Prepare the bottom electrode: in the chamber of the RF magnetron sputtering coating system, select ZnO doped with 2at% Al as the target material, install it on the target stage, and place the quartz substrate on the substrate stage; The chamber is evacuated to 3.3 x 10 -3 Pa, and then flow argon gas with a flow rate of 80 sccm, set the substrate temperature at 200° C., and sputter for 2 hours at a power of 50 W to form a bottom electrode.

[0038] 2) Preparation of the resistive switch layer: take out the prepared bottom electrode substrate, and paste a mask on one side of the substrate with aluminum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com