High-temperature coefficient and high-stability room temperature switch nanocomposite

A nano-composite material and composite material technology, applied in the field of new intelligent nano-composite functional materials, can solve problems such as undeveloped application research, and achieve the effects of enhancing interface affinity, improving on-off ratio, and improving transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

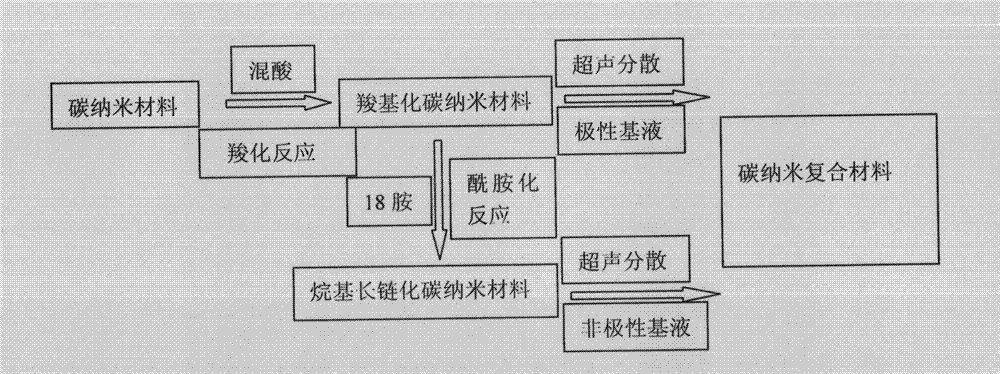

Method used

Image

Examples

Embodiment 1

[0032] Example 1, using chemical surface modification to disperse carbon nanomaterials in strong polar solvents such as glycerin and deionized water, the steps for preparing such room temperature switching carbon nanocomposites are as follows:

[0033] (1) the volume ratio of configuration vitriol oil and concentrated nitric acid is: the mixed acid of 3 / 1;

[0034] (2) carbon nanoparticles are put into mixed acid to carry out carboxylation reaction, the reaction ratio of mixed acid and carbon nanomaterial is 100ml: 0.1g;

[0035] (3) The reaction methods of the mixed acid and the carbon nanomaterials are: carbon nanotubes, 50W ultrasonic reaction at room temperature for 6h. Carbon black, fullerene, and nano-graphite flakes were refluxed in the mixed acid solution at room temperature for 4 hours. Graphene, reflux in mixed acid solution at room temperature for 2h;

[0036] (4) The reaction product is repeatedly washed by a high-speed centrifuge (10000rpm) until the pH value of...

Embodiment 2

[0038] Example 2, using chemical surface modification to disperse carbon nanomaterials in 20 alkane (36.4°C), 19 alkane (32°C), 18 alkane (28°C), 16 alkane (18.1°C), methyl palmitate (29°C) When waiting for non-polar solvents, the steps for preparing such room temperature switching carbon nanocomposites are as follows:

[0039] (1) the carboxylated carbon nanomaterial and 18 amine are mixed evenly in a ratio of 1: 4 with a mass ratio;

[0040] (2) Place the mixture in a closed container and react at 95°C for 96h;

[0041] (3) after the reaction finishes, wash the reactant with a large amount of ethanol. After repeating 3 to 5 times, filter the reactant with a microporous filter membrane with a pore size of 0.2um to ensure that the redundant 18 amine impurities on the surface of the nanomaterial are washed away, and then the After filtration, the product was placed in a vacuum environment and dried at room temperature for 24 hours;

[0042] (4) Disperse the surface-modified n...

Embodiment 3

[0043] Example 3, using a dispersant (sodium lauryl sulfate) to modify carbon nanomaterials to disperse them in strong polar solvents such as glycerin and deionized water, the steps for preparing such room temperature switching carbon nanocomposites are as follows:

[0044] (1) configuration mass fraction is 1% sodium lauryl sulfate-deionized water mixture base liquid;

[0045] (2) Pour the carbon nanomaterial into the above-mentioned base liquid with a concentration of 50mg / l;

[0046] (3) Use a plug-in ultrasonic device with a power of 500W to perform ultrasonic treatment on the deionized water mixture base liquid mixed with carbon nanomaterials and sodium lauryl sulfate, and the ultrasonic time is based on the formation of a uniform suspension;

[0047] (4) The mixture is filtered using a microporous membrane with a pore size of 0.2um, and repeatedly washed in deionized water by a high-speed centrifuge (10000rpm) to ensure removal of excess sodium lauryl sulfate;

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com