A kind of plant-type enteric-coated soft capsule

An enteric-coated soft capsule, plant-based technology, applied in the directions of capsule delivery, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problems of easy cracking of the coating film, waste of resources, complicated processes, etc. The effect of coating process, environmental protection and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

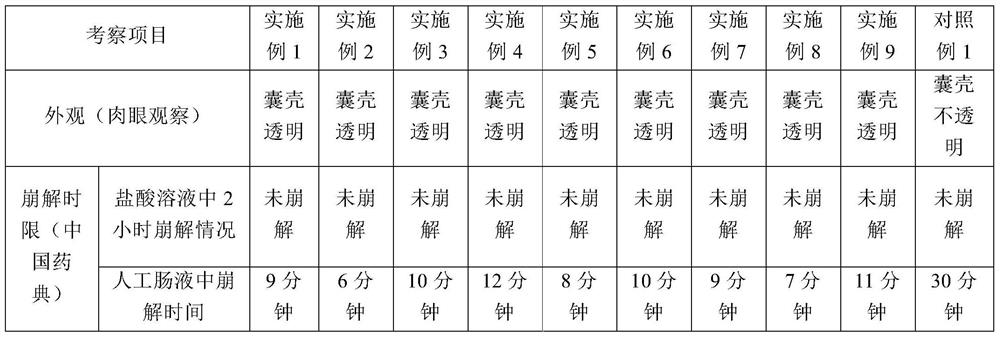

Examples

Embodiment 1

[0028] Example 1: Preparation of garlic oil plant-type enteric-coated soft capsules

[0029] 1. Prepare glue solution

[0030] a. Weigh 0.5 parts by mass of low-ester pectin and 10 parts by mass of glycerin, and mix them evenly to obtain the first liquid;

[0031] b. Take 0.001 parts by mass of calcium chloride, add it to 30 parts by mass of purified water, stir to make it completely dissolve, and obtain the second liquid;

[0032] c. Under stirring, add the first liquid into the second liquid, stir evenly, then add 2 parts by mass of carrageenan, keep heating and stirring at 95°C for 1 hour, and then remove the air bubbles in the glue by vacuuming to obtain the glue liquid.

[0033] 2. Preparation of Filling

[0034] Stir and mix 10 parts by mass of garlic oil, 89 parts by mass of soybean oil and 1 part by mass of natural vitamin E as a filling, and set aside.

[0035] 3. Compressed soft capsules

[0036] Install the soft capsule pill pressing equipment, transport the gl...

Embodiment 2

[0039] Example 2: Preparation of garlic oil plant-type enteric-coated soft capsules

[0040] 1. Prepare glue solution

[0041] a. Weigh 4 parts by mass of amide pectin and 20 parts by mass of glycerin, and mix them evenly to obtain the first liquid;

[0042] b. Weigh 0.03 parts by mass of calcium chloride, add it to 50 parts by mass of purified water, and stir to completely dissolve it to obtain the second liquid;

[0043] c. Add the first liquid into the second liquid under stirring, stir evenly, then add 40 parts by mass of gelatin, keep heating and stirring at 75°C for 2 hours, and then remove the air bubbles in the glue liquid by vacuuming to obtain the plant of the present invention The glue of type enteric-coated soft capsule.

[0044] 2. Preparation of Filling

[0045] Mix 10 parts by mass of garlic oil, 89 parts by mass of soybean oil and 1 part by mass of natural vitamin E as a filler and set aside.

[0046] 3. Compressed soft capsules

[0047] Install the soft c...

Embodiment 3

[0050]Example 3: Preparation of garlic oil plant-type enteric-coated soft capsules

[0051] 1. Prepare glue solution

[0052] a. Weigh 10 parts by mass of sodium alginate and 35 parts by mass of glycerin, and mix them evenly to obtain the first liquid;

[0053] b. Take 1 mass part of calcium chloride, add it to 70 mass parts of purified water, stir to make it completely dissolve, and obtain the second liquid;

[0054] c. Add the first liquid to the second liquid under stirring, stir evenly, then add 40 parts by mass of gelatin, keep heating and stirring at 60°C for 3 hours, and then remove the air bubbles in the glue liquid by vacuuming to obtain the plant of the present invention The glue of type enteric-coated soft capsule.

[0055] 2. Preparation of Filling

[0056] 10 parts by mass of garlic oil, 89 parts by mass of soybean oil and 1 part by mass of natural vitamin E are uniformly mixed as a filler and set aside.

[0057] 3. Compressed soft capsules

[0058] Install t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com