Harmless treatment and recycling system for oily garbage

A technology of harmless treatment and garbage, applied in the direction of solid waste removal, etc., can solve problems such as environmental hazards, achieve good effects, be conducive to environmental protection, and facilitate industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

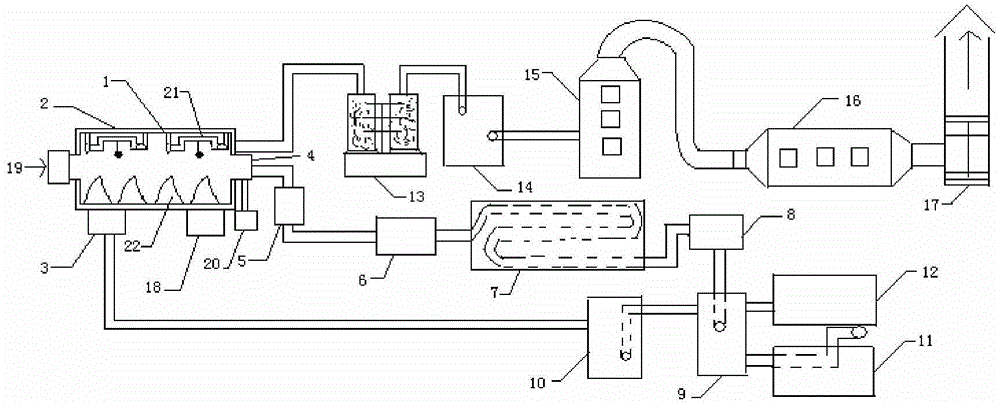

[0022] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, to further clarify the advantages of the present invention and its outstanding contributions to the prior art. It is understandable that the following examples are only detailed descriptions of the preferred embodiments of the present invention. , Should not be interpreted as any limitation to the technical solution of the present invention.

[0023] Such as figure 1 As shown, the oily waste and dead pig waste, appropriate amount of sodium silicate, soda ash, non-hydrogen catalyst, defoamer, and flocculant are added to the starting combustion chamber 3 from the feed port 19, and the reactor 1 is heated to 300 As the temperature rises, the gas and oily liquid produced by the reaction gradually flow out of the oil and gas 4 through the catalytic tower 5 to accelerate the complete reaction, and then enter the precipitation tank 6, where the entraine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com