Method for preparing phosphorous-nitrogen synergistic wood fire retardant

A flame retardant and wood technology, applied in the field of flame retardants, can solve the problems that cannot fully meet the needs of the market, and achieve the effects of improving chemical atom utilization, high flame retardant efficiency, and reducing side effects such as salting out and hygroscopicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

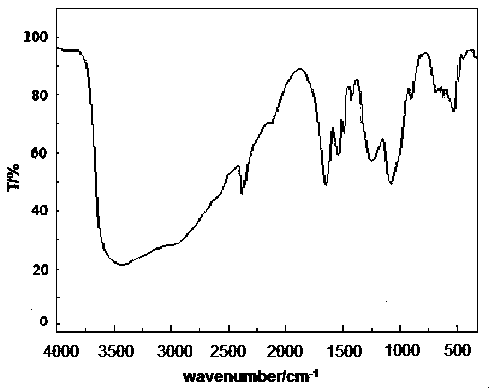

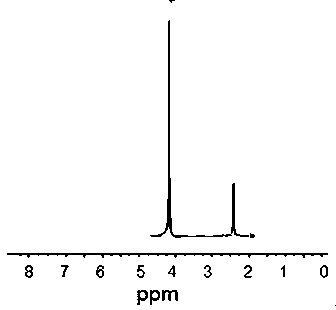

Image

Examples

Embodiment 1

[0028] A method for preparing a phosphorus-nitrogen synergistic wood flame retardant, characterized in that the method comprises the following steps:

[0029] (1) Preparation of reaction equipment: Install a stirrer, a high-efficiency reflux condenser in a 250ml reactor, and install a drying tube and an HCL absorption device on the top of the condenser;

[0030] (2) Take 15.75g (0.1mol) of trimethylolmethylamine hydrochloride and 80ml of dioxane and place them in the reactor of step (1), drive out the air in the reactor with nitrogen, and lower the temperature of the reaction system Cool down to below 10°C, drop 15.35g (0.1mol) phosphorus oxychloride into the reactor, control the reaction temperature not higher than 20°C during the dropping process, and raise the temperature to 85°C within 1 hour after the dropping, Insulation reaction at this temperature for 5 hours, after the generated HCL is exhausted, the reaction solution a is obtained;

[0031] Lower the temperature of ...

Embodiment 2

[0034] A method for preparing a phosphorus-nitrogen synergistic wood flame retardant, characterized in that the method comprises the following steps:

[0035] (1) Preparation of reaction equipment: Install a stirrer, a high-efficiency reflux condenser in a 250ml reactor, and install a drying tube and an HCL absorption device on the top of the condenser;

[0036] (2) Take 15.75g (0.1mol) of trimethylolmethylamine hydrochloride and 100ml of diethylene glycol dimethyl ether and place them in the reactor of step (1), drive out the air in the reactor with nitrogen, and put Cool the temperature of the reaction system to below 10°C, add 15.35g (0.1mol) phosphorus oxychloride dropwise into the reactor, control the reaction temperature not higher than 20°C during the dropping process, and raise the temperature to 100°C within 1 hour after the dropwise addition °C, keep the reaction at this temperature for 4 hours, and after the generated HCL is exhausted, the reaction solution a is obt...

Embodiment 3

[0040] A method for preparing a phosphorus-nitrogen synergistic wood flame retardant, characterized in that the method comprises the following steps:

[0041] (1) Preparation of reaction equipment: Install a stirrer, a high-efficiency reflux condenser in a 250ml reactor, and install a drying tube and an HCL absorption device on the top of the condenser;

[0042] (2) Take 15.75g (0.1mol) of trimethylolmethylamine hydrochloride and 110ml of tetrahydrofuran and place them in the reactor of step (1), drive out the air in the reactor with nitrogen, and cool the temperature of the reaction system to 10 Below ℃, drop 15.35g (0.1mol) phosphorus oxychloride into the reactor, control the reaction temperature not higher than 20℃ during the dropping process, and raise the temperature to 65℃ within 1 hour after the dropping, at this temperature Insulation reaction for 6 hours, after the generated HCL is exhausted, the reaction solution a is obtained;

[0043]Lower the temperature of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com