Preparation method of SiC nanowire-toughened SiC ceramic coating on surface of C/C composite

A technology of nanowire toughening and composite materials, which is applied in the field of preparation of SiC nanowire toughened SiC ceramic coatings on the surface of C/C composite materials, can solve the problems of easy cracking of SiC ceramic coatings, and achieve the improvement of anti-oxidation effect, The effect of relieving thermal stress and stabilizing the rate of oxidation weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

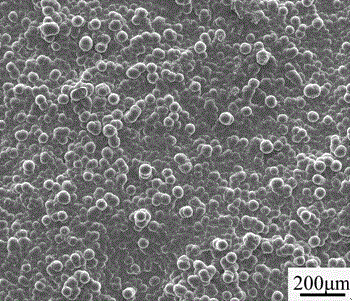

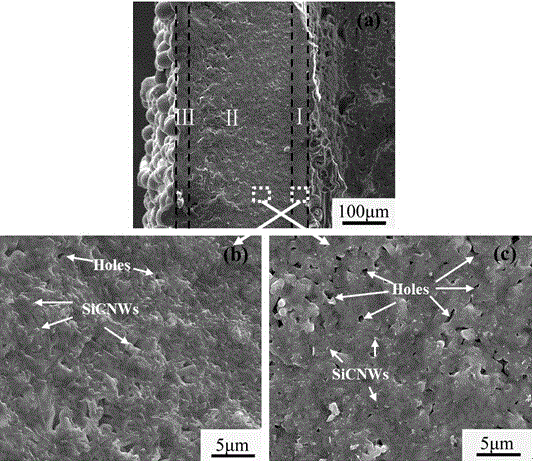

[0028] Set the density to 1.70g / cm 3 C / C composite material processed into 20×10×5mm 3 The samples are polished with No. 800 and No. 1000 sandpaper in turn, washed with distilled water ultrasonically, dried in an oven at 120°C, and immersed in a 10% by mass nickel nitrate aqueous solution until there are no bubbles on the surface of the sample. After the sample was dried in an oven at 80°C, it was used as a deposition substrate.

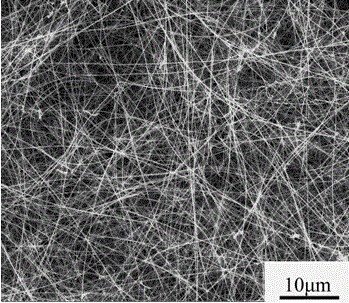

[0029] A bundle of carbon fibers is used to bundle the soaked C / C composite material and hang it in the deposition area of a vertical chemical vapor deposition furnace. Evacuate the deposition furnace to 1 kPa, keep the vacuum for 30 minutes to confirm that the sealing performance of the deposition furnace is intact, and then ventilate to normal pressure, and this process is repeated three times. Then the deposition furnace was heated at a rate of 10°C / min to 1100°C, and argon protection was passed into the deposition furnace at a flow rate of 200 scc...

Embodiment 2

[0032] Set the density to 1.68g / cm 3 C / C composite material processed into 20×10×5mm 3 The samples are polished with No. 800 and No. 1000 sandpaper in turn, washed with distilled water ultrasonically, dried in an oven at 120 ℃, and immersed in a 5% nickel nitrate aqueous solution by mass until there are no bubbles on the surface of the sample. After the sample was dried in an oven at 80°C, it was used as a deposition substrate.

[0033] A bundle of carbon fibers is used to bundle the soaked C / C composite material and hang it in the deposition area of a vertical chemical vapor deposition furnace. Evacuate the deposition furnace to 1 kPa, keep the vacuum for 30 minutes to confirm that the sealing performance of the deposition furnace is intact, and then ventilate to normal pressure, and this process is repeated three times. Then, the deposition furnace was heated to 1050°C at a rate of 10°C / min, and argon protection was passed into the deposition furnace at a flow rate of 200 scc...

Embodiment 3

[0036] Set the density to 1.75g / cm 3 C / C composite material processed into 20×10×5mm 3 The samples are polished with No. 800 and No. 1000 sandpaper in turn, washed clean with distilled water ultrasonically, dried in an oven at 120°C, and immersed in a 15% nickel nitrate aqueous solution by mass until there are no bubbles on the surface of the sample. After the sample was dried in an oven at 80°C, it was used as a deposition substrate.

[0037] A bundle of carbon fibers is used to bundle the soaked C / C composite material and hang it in the deposition area of a vertical chemical vapor deposition furnace. Evacuate the deposition furnace to 1 kPa, keep the vacuum for 30 minutes to confirm that the sealing performance of the deposition furnace is intact, and then ventilate to normal pressure, and this process is repeated three times. Then the deposition furnace was heated up to 1200°C at a rate of 12°C / min, and argon protection was passed into the deposition furnace at a flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com