Thiophilic porous material, and preparation method and application thereof

A technology of porous materials and organic solvents, applied in the field of preparation of affinity sulfur-loving materials, can solve the problems of high preparation cost, inability to withstand high pressure, low mechanical strength, etc., and achieve simple preparation method, simple and convenient preparation process, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

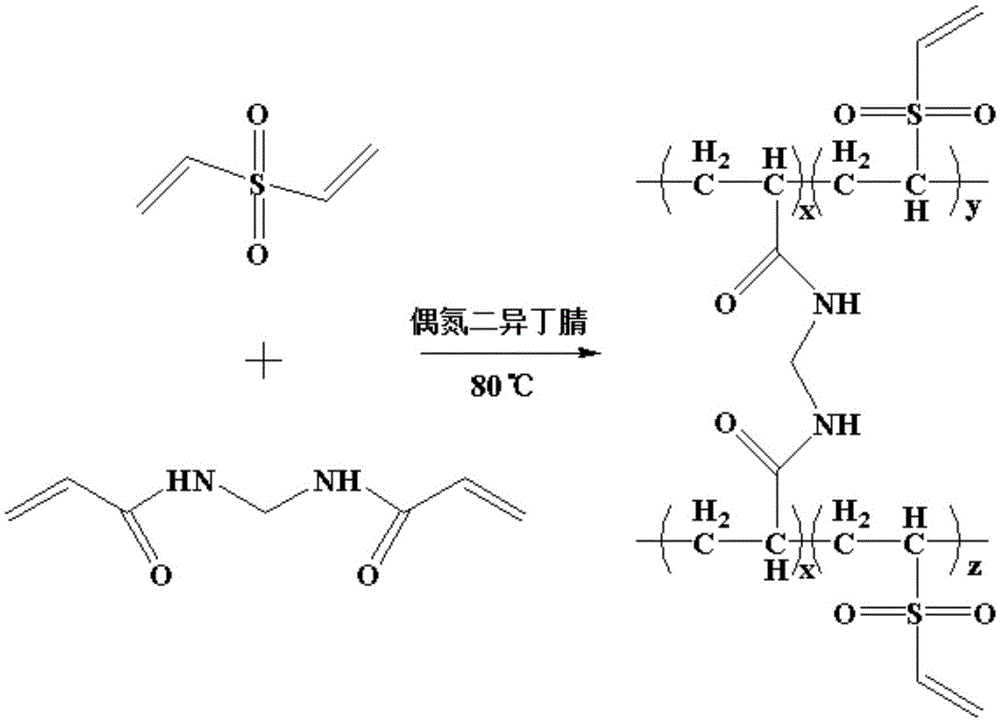

[0020] The invention provides a method for preparing a sulfur-loving porous material, wherein the preparation method comprises: in the presence of an initiator, divinyl sulfone, N,N-methylenebisacrylamide and a first organic solvent mixed to obtain a thiophilic porous material. Its preparation principle is as figure 1 shown.

[0021] The above design forms a cross-linked skeleton structure and interpenetrating channels through the copolymerization of divinyl sulfone and the cross-linking agent N,N-methylenebisacrylamide under the initiation of a free radical reaction initiator, so that in a certain In the presence of concentrated salt, it can specifically interact with compounds containing disulfide groups and antibodies, thereby achieving separation and purification. At the same time, through the above technical scheme, it is proposed for the first time to introduce sulfone groups into thiophilic porous materials by the method of double bond polymerization. Good repeatabil...

Embodiment 1

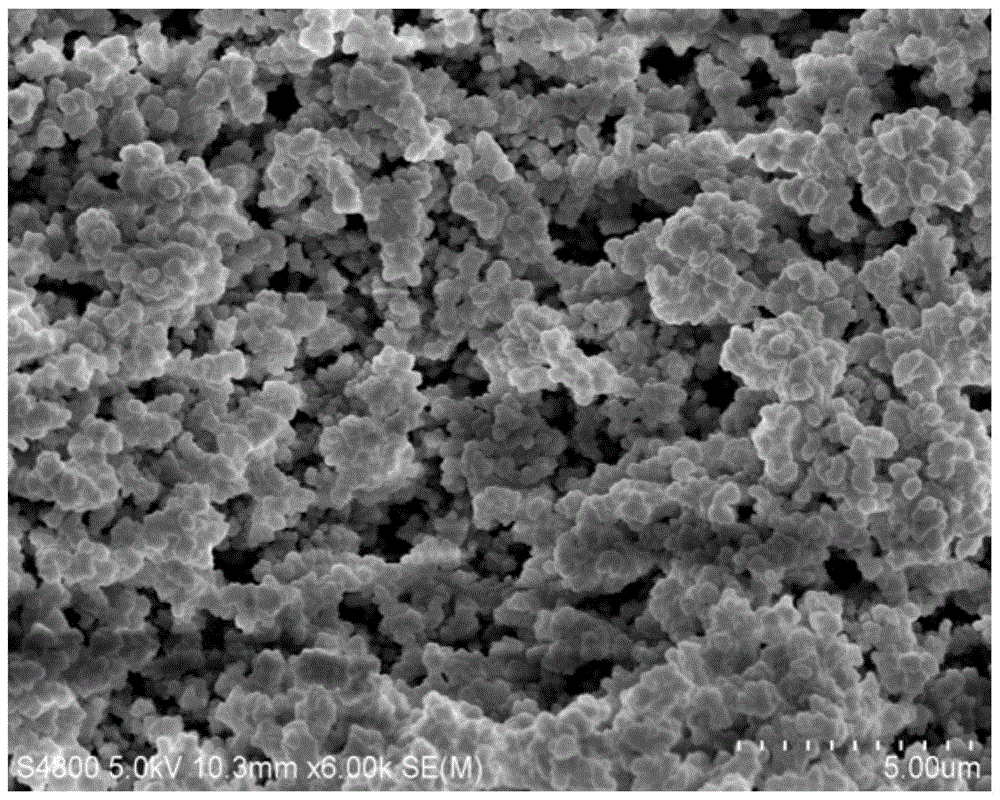

[0043] Dissolve 12.5mg of divinyl sulfone and 30.0mg of N,N-methylenebisacrylamide in 85.0μL of dimethyl sulfoxide and place in a centrifuge tube, then add 85.0μL of dodecanol and 1.0mg of azobis isobutyronitrile, then placed in a vortex oscillator for full dissolution, and then ultrasonically degassed for 20.0 min to obtain a uniformly mixed solution, then seal both ends of the centrifuge tube with silicone rubber, and place the sealed centrifuge tube Put it in a water bath at a temperature of 85.0°C for 10.0 hours to prepare the mixture M1; take out the prepared mixture M1 and cut it into small pieces, then take 3.0 g of the mixture M1 and put it in a Soxhlet extractor, add methanol, and place in The mixture M2 was obtained by extracting at 110.0°C for 24.0 hours; the mixture M2 was dried in a vacuum oven at a temperature of 100.0°C for 12.0 hours to obtain a sulfur-philic porous material A1.

Embodiment 2

[0045] 1) Rinse the empty capillary column with a diameter of 75.0 μm with 0.1mol / L NaOH solution for 30.0min, then rinse the capillary with deionized water for 30.0min, then rinse the capillary with 0.1mol / L HCl solution for 30.0.min, and then use Rinse the capillary with ion water until the pH value of the effluent liquid is 7.0, then rinse the capillary with methanol solution for 30.0min, and blow dry with nitrogen; then inject a mixture of methanol and 3-(methacryloyloxy)propyltrimethoxysilane into the capillary (Wherein, relative to 1.3 parts by weight of 3-(methacryloyloxy)propyltrimethoxysilane, the amount of methanol used is 1 part by weight) and then reacted at a temperature of 50.0°C for 12.0h; Rinse, and finally dry the above-mentioned pretreated capillary with nitrogen for use;

[0046] 2) Dissolve 12.5mg of divinylsulfone and 30.0mg of N,N-methylenebisacrylamide in 85.0μL of dimethyl sulfoxide, then add 85.0μL of dodecanol and 1.0mg of azobisisobutyronitrile, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com