Fluoroalkyl modified acrylate-containing low-surface energy, drag reduction and fouling prevention coating and preparation method thereof

An acrylate and low surface energy technology, which is applied in the field of acrylate low surface energy drag-reducing anti-fouling coatings and its preparation, can solve the problems of poor adhesion of anti-fouling coatings, rapid failure of anti-fouling effects, and large underwater frictional resistance. , to achieve the effect of smooth surface, convenient construction and improved bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

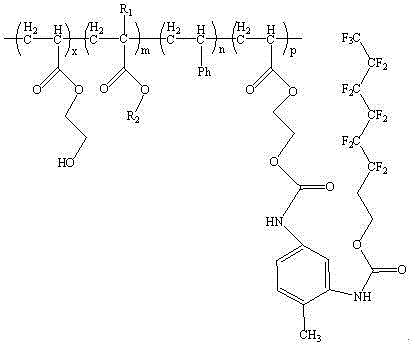

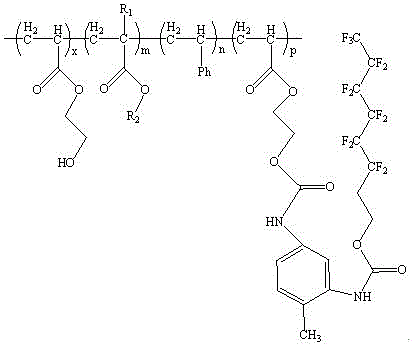

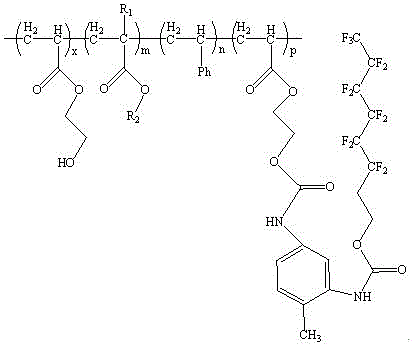

Image

Examples

Embodiment 1

[0051] Add the above-mentioned fluoroalkyl-modified acrylic low surface energy resin I, rosin, and organic solvent into the dispersion tank, fully disperse for 10 minutes, add additives, composite antifouling agents, pigments and fillers in turn, stir and disperse for 10 minutes, and then ball mill for 6 hours , After checking the viscosity and fineness, the A-type component is obtained.

[0052] Class A group distribution ratio is as follows:

[0053] Fluoroalkyl modified acrylic resin I: 40 grams;

[0054] Rosin: 5 grams;

[0055] Composite antifouling agent: 20 grams of cuprous oxide, 2 grams of copper pyrithione;

[0056] Pigments and fillers: 6 grams of iron oxide red, 4.5 grams of zinc oxide, 1.5 grams of precipitated barium sulfate;

[0057] Coating additives: BYK1630.8g, BYK0520.4g, BYK3000.4g, organic bentonite 1.6g;

[0058] Mixed solvent: 8 grams of xylene, 8 grams of butyl acetate.

[0059] After the A-type component and Bayer N75 curing agent are fully mixed ...

Embodiment 2

[0061] The antifouling paint preparation process of this example is the same as that of Example 1.

[0062] Class A group distribution ratio is as follows:

[0063] Fluoroalkyl modified acrylic resin II: 40 grams;

[0064] Rosin: 5 grams;

[0065] Composite antifouling agent: 20 grams of cuprous oxide, 2 grams of copper pyrithione;

[0066] Pigments and fillers: 6 grams of iron oxide red, 4.5 grams of zinc oxide, 1.5 grams of precipitated barium sulfate;

[0067] Coating additives: BYK1630.8g, BYK0520.4g, BYK3000.4g, organic bentonite 1.6g;

[0068] Mixed solvent: 8 grams of xylene, 8 grams of butyl acetate.

Embodiment 3

[0070] The antifouling paint preparation process of this example is the same as that of Example 1.

[0071] Class A group distribution ratio is as follows:

[0072] Fluoroalkyl modified acrylic resin III: 40 grams;

[0073] Rosin: 5 grams;

[0074] Composite antifouling agent: 20 grams of cuprous oxide, 2 grams of copper pyrithione;

[0075] Pigments and fillers: 6 grams of iron oxide red, 4.5 grams of zinc oxide, 1.5 grams of precipitated barium sulfate;

[0076] Coating additives: BYK1630.8g, BYK0520.4g, BYK3000.4g, organic bentonite 1.6g;

[0077] Mixed solvent: 8 grams of xylene, 8 grams of butyl acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com