Evaluation method for service life of lead-based anode material

A technology of anode material and evaluation method, which is applied in anodizing, measurement of the force of change of optical properties when the material is stressed, electrodes, etc., can solve the problem of unpredictable service life of lead-based anodes and complex application environment conditions, etc problems, to achieve the effect of low cost, simple ingredients and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The evaluation method of the service life of the lead-based anode material of the present embodiment may further comprise the steps:

[0044] Step 1: After polishing the Pb-0.5% Ca alloy lead-based anode material with 1000# water sandpaper, use a woolen polishing cloth to polish the surface of the lead-based anode material until there is no obvious scratch, and then use acetic acid and hydrogen peroxide with a volume ratio of 2.5 The mixed solution is used to chemically treat the surface of the polished lead-based anode material;

[0045] Step 2: Using CrO 3 110g / L, H 2 SO 4 26g / L, NH 4 F is 5g / L, NaCl is 2g / L mixed solution to electrolyze the lead-based anode material, wherein, the current density of electrolysis is 25A / dm 2 , the electrolyte temperature is 40°C, and the electrolysis time is 5min, 10min, 15min, 20min, 25min and 30min;

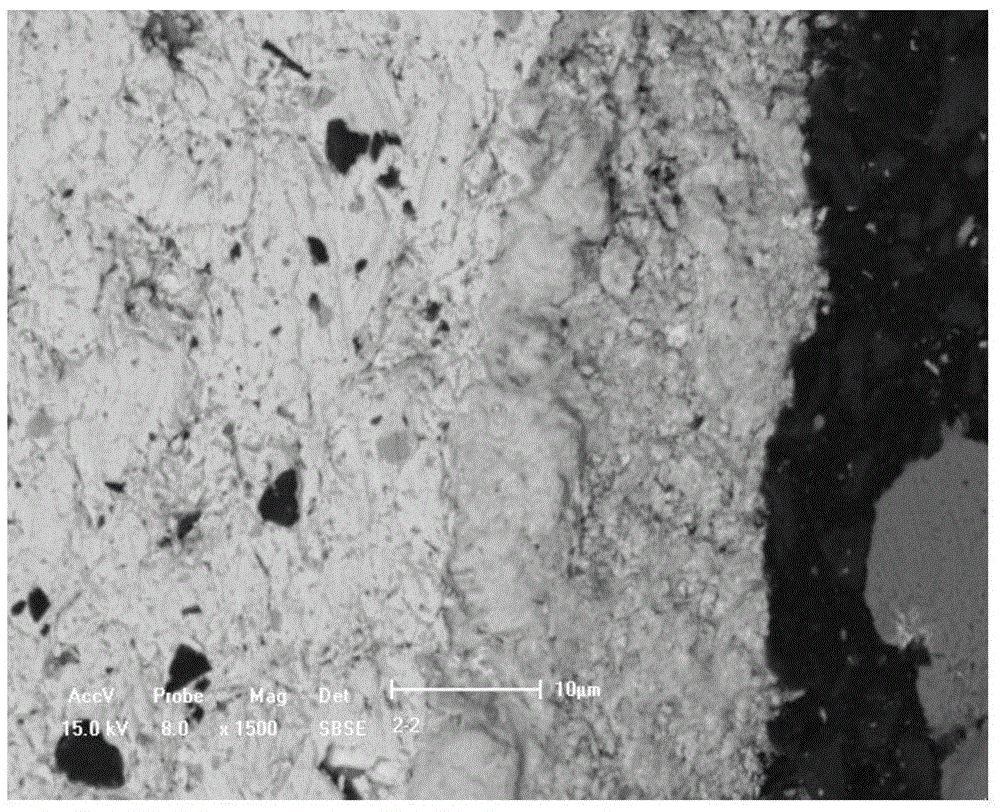

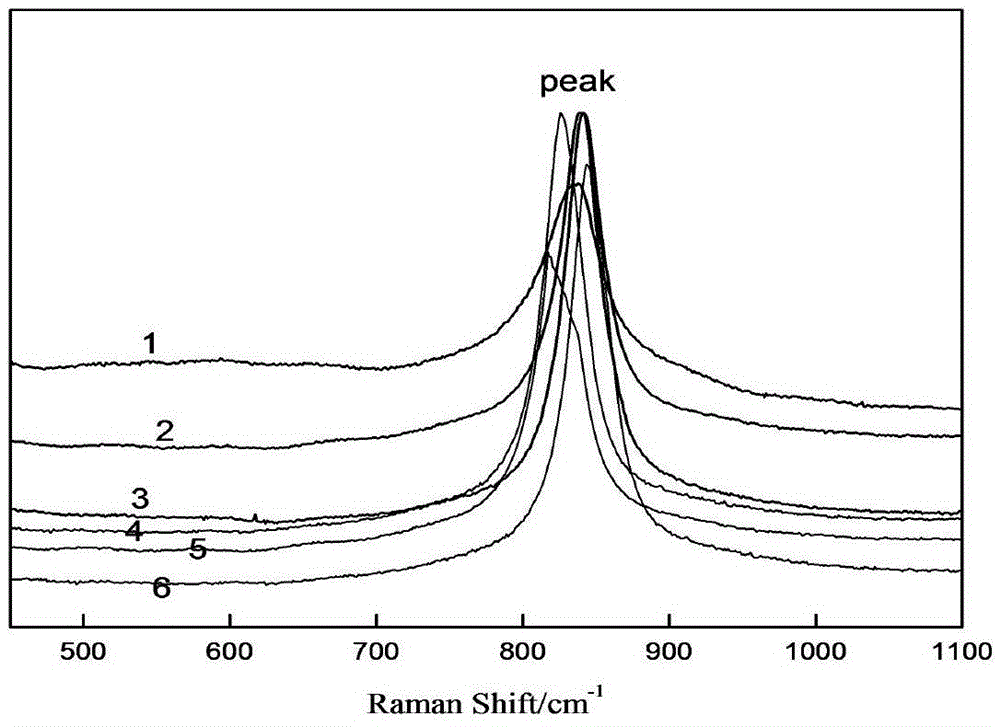

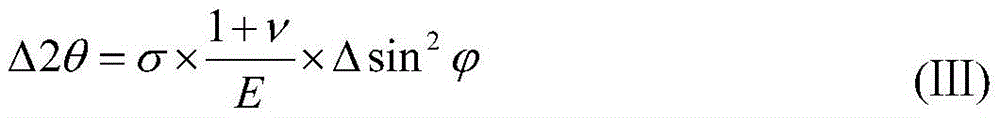

[0046] Step 3: Use SEM to analyze the cross-section of the oxide film on the surface of the lead-based anode material under diffe...

Embodiment 2

[0059] The evaluation method of the service life of the lead-based anode material of the present embodiment may further comprise the steps:

[0060] Step 1: After the lead-based anode material of the Pb-1%Ca-1.2%Sn alloy is polished with 1200# water sandpaper, the surface of the Pb-1%Ca-1.2%Sn alloy is polished to no obvious scratches with a woolen polishing cloth trace, and then use a mixed solution of acetic acid and hydrogen peroxide with a volume ratio of 3 to chemically treat the surface of the polished lead-based anode material;

[0061] Step 2: Using CrO 3 170g / L, H 2 SO 4 18g / L, NH 4 F is 2g / L, NaCl is 3g / L mixed solution to electrolyze Pb-1%Ca-1.2%Sn alloy lead-based anode material, wherein, the current density of electrolysis is 35A / dm 2 , the electrolyte temperature is 50°C, and the electrolysis time is 5min, 10min, 15min, 20min, 25min and 30min;

[0062] Step 3: Use SEM to analyze the cross-section of the oxide film on the surface of the lead-based anode mater...

Embodiment 3

[0074] The evaluation method of the service life of the lead-based anode material of the present embodiment may further comprise the steps:

[0075] Step 1: after the lead-based anode material of Pb-1.2%Sn-0.5%Ag alloy is polished by 1400# water sandpaper, the surface of the lead-base anode material of Pb-1.2%Sn-0.5%Ag alloy is treated with wool polishing cloth Polishing until there are no obvious scratches, and then using a mixed solution with a volume ratio of acetic acid and hydrogen peroxide of 4 to chemically treat the surface of the polished lead-based anode material;

[0076] Step 2: Using CrO 3 190g / L, H 2 SO 4 12g / L, NH 4 F is 4g / L, NaCl is 3g / L mixed solution to electrolyze Pb-1%Sn-0.3%Ag alloy lead-based anode material, wherein, the current density of electrolysis is 40A / dm 2 , the electrolyte temperature is 60°C, and the electrolysis time is 5min, 10min, 15min, 20min, 25min and 30min;

[0077] Step 3: Use SEM to analyze the cross-section of the oxide film on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Stress value | aaaaa | aaaaa |

| Stress value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com