Permeable hydraulic tunnel lining and manufacturing method

A technology for hydraulic tunnels and manufacturing methods, which is applied in tunnel linings, shaft linings, tunnels, etc., can solve problems affecting structural durability and safe operation, prone to corrosion, and high construction requirements, so as to avoid durability, low cost, The effect of simple design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

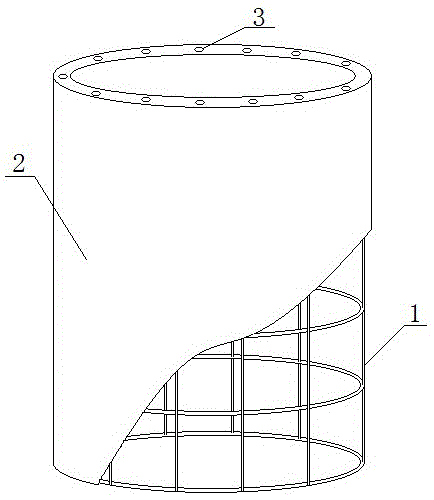

[0033] Such as figure 1 As shown, a permeable hydraulic tunnel lining designed by the present invention includes a cylindrical reinforced grid 1 and a permeable concrete 2 whose section outer diameter is compatible with the hydraulic tunnel inner diameter during the actual application process, wherein the permeable type Concrete 2 is composed of cement, gravel, sand, water, and water-reducing agent, and the amount of cement per cubic meter of permeable concrete 2 is 350kg-450kg, and the weight ratio of cement: gravel: sand: water: water-reducing agent 1: 3~5: 0.5~1: 0.3~0.35: 0.01~0.02; the rib grid in the tubular rib grid 1 is composed of FRP fiber bundles interweaving in the circumferential and longitudinal directions; The surface of each FRP fiber bundle in the shaped rib grid 1 is covered with epoxy resin, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com