Acetone sensor based on NiO/ZnO heterostructure nanoflower sensitive material and preparation method of acetone sensor

A technology of sensitive materials and heterostructures, applied in the fields of nanotechnology, material resistance, nanotechnology for materials and surface science, can solve the problems of high detection temperature, low sensitivity, etc. Simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

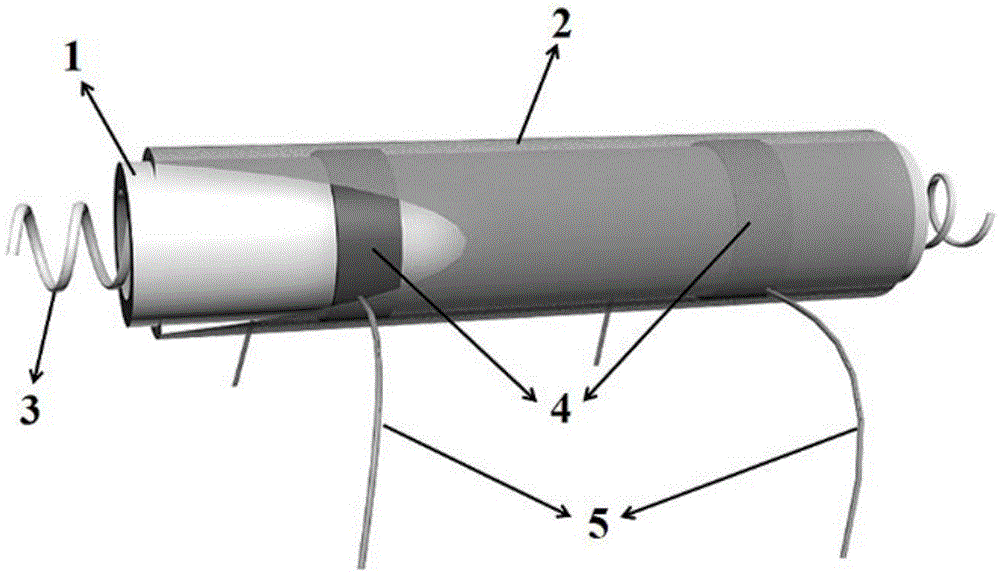

[0041] Using NiO / ZnO heterostructure nanoflowers as sensitive materials to make acetone sensors, the specific manufacturing process:

[0042] 1. First, 1.0g of Zn(CH 3 COO) 2 2H 2 Dissolve O in 100mL of deionized water, and keep stirring until it is completely dissolved; then slowly add 3.4mL of ammonia water to it until the solution is clear;

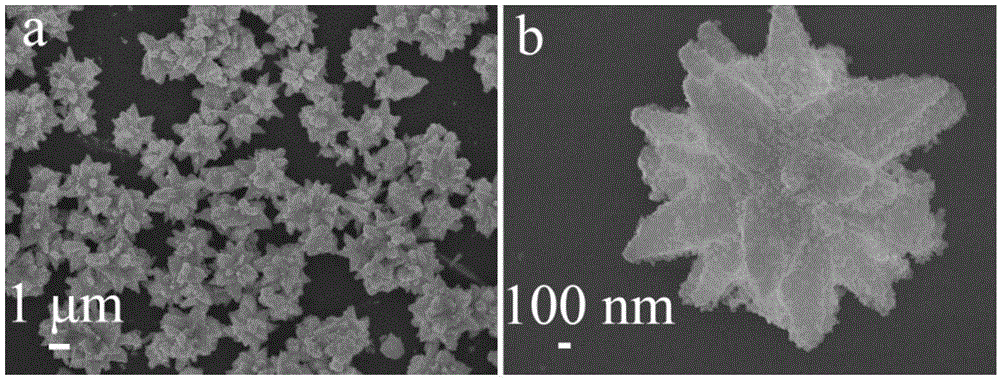

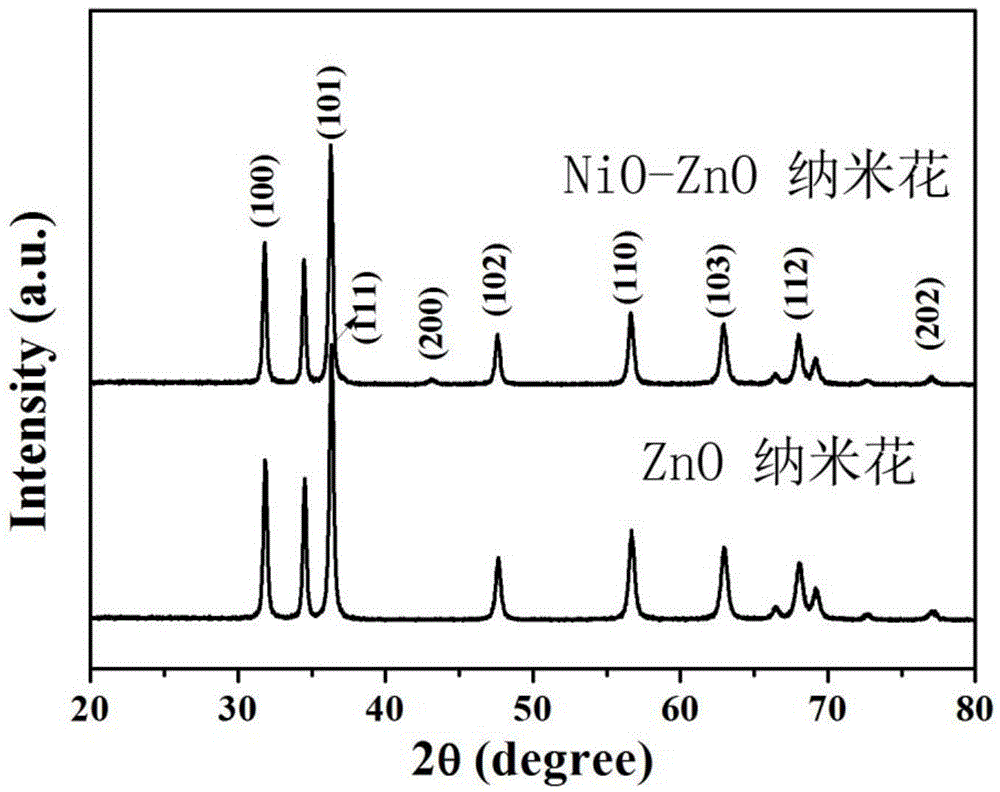

[0043] 2. Transfer the above solution to a constant temperature water bath, keep it at 80°C for 60 minutes, take it out, cool it down to room temperature naturally, wash the resulting precipitate with deionized water and ethanol for several times, and then dry it at room temperature before putting it in Calcined at 450°C for 1.5 hours to obtain ZnO nanoflowers assembled from ZnO nanoparticles;

[0044] 3. Take 35 mg of the above-mentioned ZnO nanoflower powder and add it to 6 mL of ethanol, and ultrasonically stir for 20 minutes to completely disperse the ZnO nanoflower powder in the ethanol. Then add 10.0mgNi(NO3)2·6H2O, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com