Method for measuring separation coefficient during process of silicon isotope separation (chemical exchange method) and apparatus thereof

A technology of chemical exchange and silicon isotope, applied in the direction of measuring devices, scientific instruments, analytical materials, etc., can solve the problems such as no longer applicable, and achieve the effect of convenient operation, real and reliable results, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

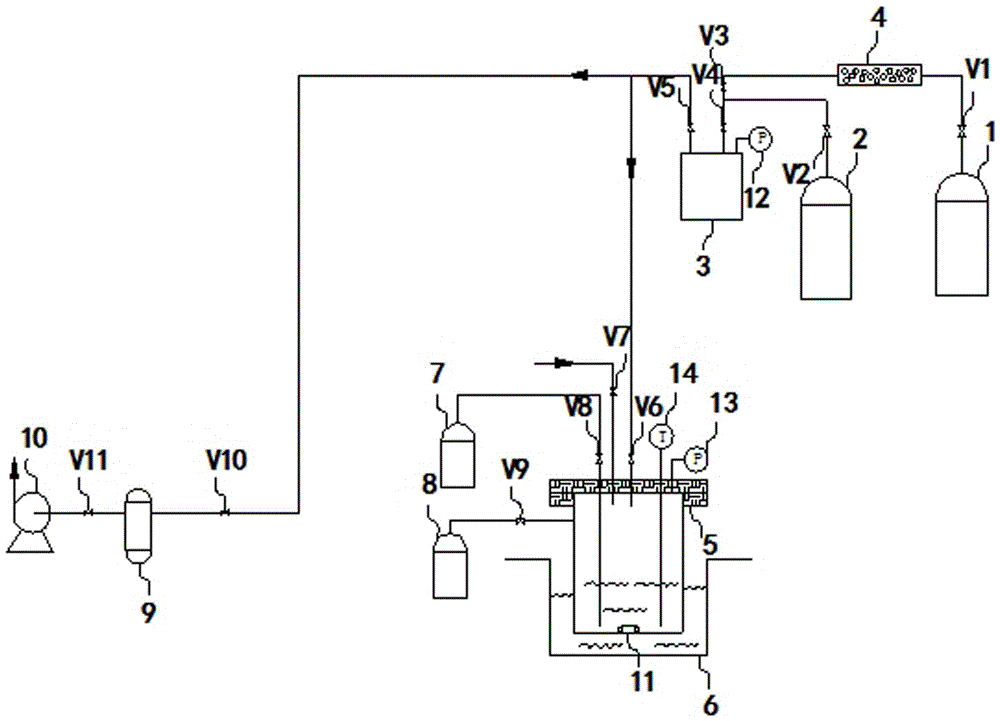

Embodiment 1

[0054] In this embodiment, methanol is used as a complexing agent, and SiF 4 The silicon isotope chemical exchange reaction is carried out between the gas and the silicon tetrafluoride methanol complex, and the silicon isotope separation coefficient at different temperatures and pressures is measured.

[0055] The specific process is as follows.

[0056] 1. Methanol needs to be dehydrated before the experiment to keep the water content below 50ppm. The purity of SiF4 gas used is higher than 99.99%, and the purity of nitrogen gas is higher than 99.9999%.

[0057] 2. Repeat vacuuming and nitrogen filling for the whole device 3 times, and finally vacuumize.

[0058] 3. Add 100ml of methanol into the chemical exchange reaction kettle; put distilled water into the refrigeration heater with stirring and temperature adjustment function, keep at 2°C, and set the rotation number of the stirring rotor at 50r / min.

[0059] 4. Inject SiF with a pressure of 0.1MPa into the chemical exch...

Embodiment 2

[0065] In this embodiment, ethanol is used as a complexing agent, and SiF 4 The silicon isotope chemical exchange reaction is carried out between the gas and the silicon tetrafluoride ethanol complex, and the silicon isotope separation coefficient at different temperatures and pressures is measured.

[0066] The specific process is as follows.

[0067] Before the experiment, the ethanol should be dehydrated to keep the water content below 50ppm. The amount of ethanol added is 100ml. Add distilled water and ice cubes to a freezer heating mixer and keep at 0°C.

[0068] The reaction conditions were maintained at a temperature of 0° C., a reaction pressure of 0.1 MPa, and a rotor speed of 50 r / min.

[0069] All the other operating steps are the same as in Example 1.

[0070] Through actual testing, the device of the present invention can accurately measure SiF 4 During the silicon isotope chemical exchange reaction between gas and silicon tetrafluoride ethanol complex, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com