Preparation method of silver-doped two-dimensional graphite phase carbon nitride composite photocatalyst

A graphite-phase carbon nitride and silver-doped technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult removal and stripping of sulfate radicals, and easy preparation conditions The effect of control, simple preparation method and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Pretreatment of thermal decomposition precursors

[0020] Dissolve 0.035g of silver nitrate in 2.8g of water, slowly add 7g of ammonium chloride and 3.5g of melamine under constant stirring, stir at room temperature for 20min, heat to 80°C, and keep stirring for 60min to completely volatilize the water.

[0021] (2) Silver / two-dimensional g-C 3 N 4 Preparation of Composite Photocatalyst

[0022] Add the mixture of ammonium chloride, melamine and silver nitrate dried in step (1) into a semi-closed crucible, put it into a muffle furnace, react at 400°C for 4 hours, close the muffle furnace, and grind to obtain the product.

Embodiment 2

[0024] (1) Pretreatment of thermal decomposition precursors

[0025] Dissolve 0.42g of silver nitrate in 3.5g of ethanol, slowly add 7g of ammonium chloride and 4.2g of melamine under constant stirring, stir at room temperature for 60min, heat to 100°C, and keep stirring for 30min until the ethanol is completely volatilized.

[0026] (2) Silver / two-dimensional g-C 3 N 4 Preparation of Composite Photocatalyst

[0027] Add the mixture of ammonium chloride, melamine and silver nitrate dried in step (1) into a semi-closed crucible, put it into a muffle furnace, react at 450°C for 6 hours, close the muffle furnace, and grind to obtain the product.

[0028] 1. Silver / two-dimensional g-C 3 N 4 Performance Determination of Composite Photocatalyst

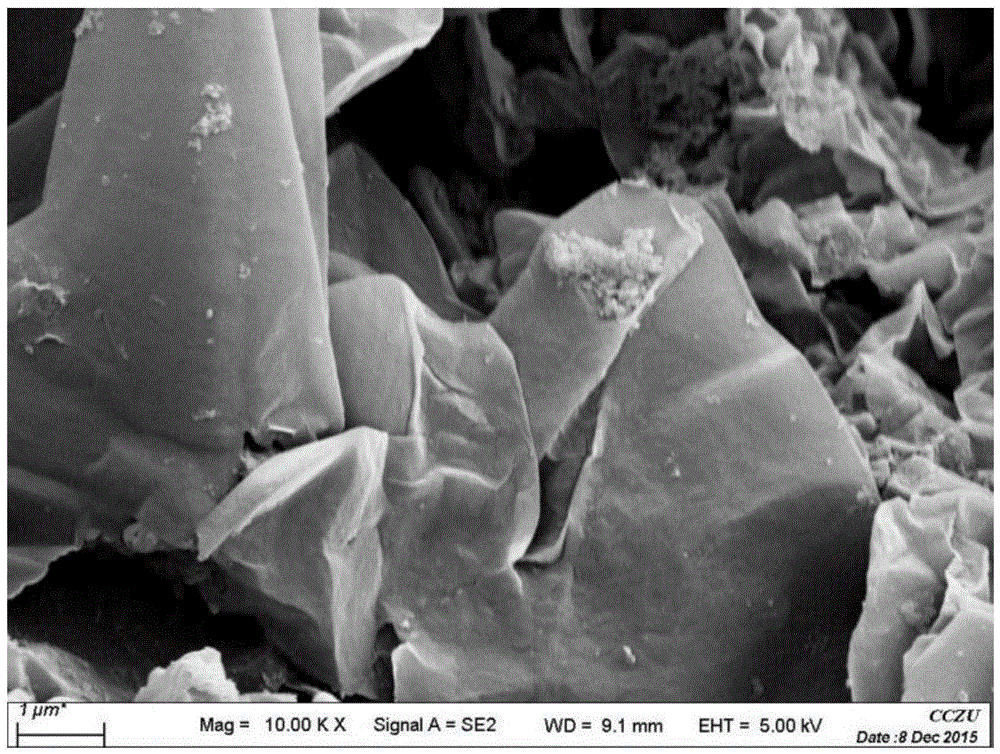

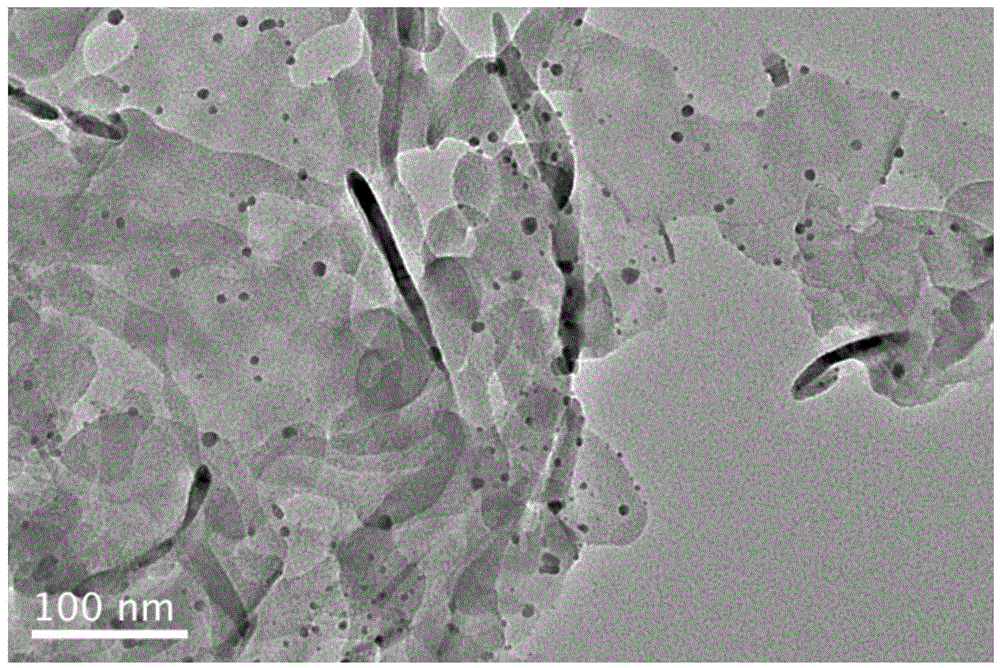

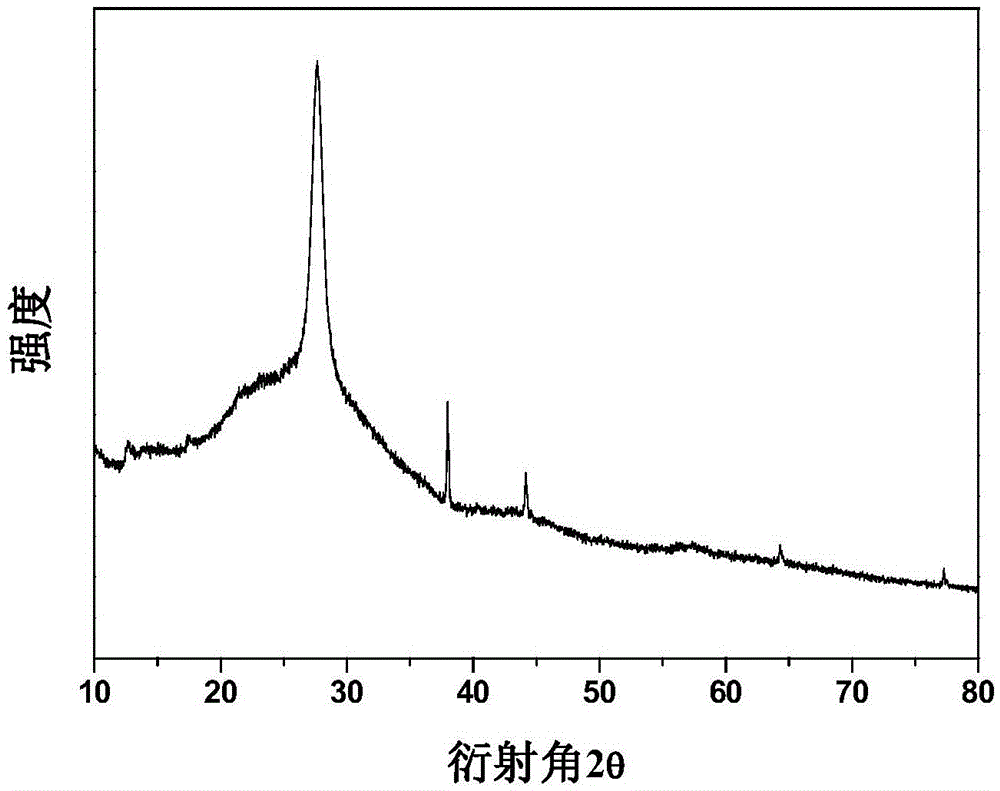

[0029] Adopt Japanese JSM-6360A type scanning electron microscope to observe the silver / two-dimensional g-C that embodiment 1 prepares 3 N 4 The morphology of the composite photocatalyst, the scanning electron microscope picture is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com