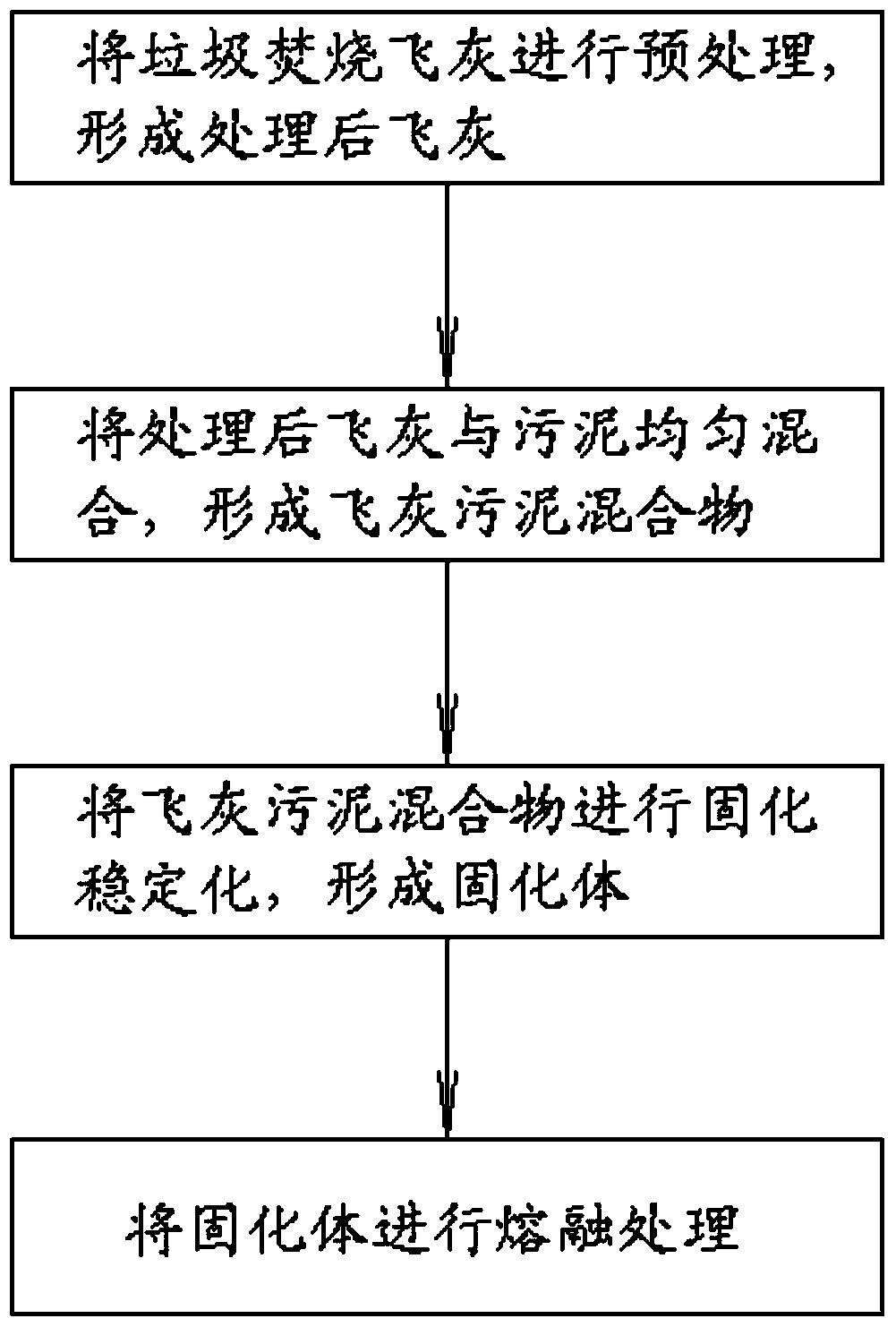

A method for melting and processing waste incineration fly ash

A technology for waste incineration fly ash and a treatment method, applied in the field of environmental engineering, can solve the problems of high cost of fly ash melting treatment, leaching of heavy metals in slag, and easy clogging of pipelines by fly ash, so as to save the cost of melting treatment and avoid two The effect of secondary pollution and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0054] Add 8 tons of tap water to 1 ton of waste incineration fly ash, mix evenly, stir for 50 minutes, use a plate and frame filter press to filter and air-dry, and mix the air-dried treated fly ash with 111kg of urban municipal dewatered sludge with a moisture content of 75%. Mix evenly to form a fly ash sludge mixture, add phosphogypsum and cement to the fly ash sludge mixture, the particle size of the phosphogypsum is 200 mesh, the content of calcium oxide in the phosphogypsum is 35%, the cement is ordinary Portland cement, The mass of phosphogypsum and cement is 247kg. After mixing evenly, it is compressed into a solidified body. The solidified body is moved into a plasma melting furnace, kept at 1000°C for 30 minutes, water-quenched and formed, and the tail gas is discharged after desulfurization and denitrification treatment.

Embodiment example 2

[0056] Add 10 tons of tap water to 1 ton of waste incineration fly ash, mix evenly, stir for 60 minutes, use a centrifuge to dehydrate and then air-dry, and mix the air-dried treated fly ash with 100kg of urban municipal dewatered sludge with a moisture content of 80% to form Fly ash sludge mixture, add phosphogypsum and cement to the fly ash sludge mixture, the particle size of phosphogypsum is 150 mesh, the content of calcium oxide in phosphogypsum is 30%, the cement is ordinary portland cement, phosphogypsum and cement The mass of each is 220kg, and after being stirred evenly, it is compressed into a solidified body. The solidified body is moved into a plasma melting furnace, kept at 1200°C for 30 minutes, water-quenched and formed, and the tail gas is discharged after desulfurization and denitrification treatment.

Embodiment example 3

[0058] Add 12 tons of tap water to 1 ton of waste incineration fly ash, mix evenly, stir for 70 minutes, use a plate and frame filter press to filter and air-dry, and mix the air-dried processed fly ash with 90.9kg of urban municipal dewatering sewage with a moisture content of 80%. Mix the mud evenly to form a fly ash sludge mixture, add phosphogypsum and cement to the fly ash sludge mixture, the particle size of the phosphogypsum is 100 mesh, the content of calcium oxide in the phosphogypsum is 33%, and the cement is ordinary Portland cement , The mass of phosphogypsum and cement is 198kg. After mixing evenly, it is compressed into a solidified body. The solidified body is moved into a plasma melting furnace, kept at 1300°C for 30 minutes, water quenched and formed, and the tail gas is discharged after desulfurization and denitrification treatment.

[0059] Through the above three embodiments, it can be concluded that the melting treatment method for waste incineration fly as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com