A laser welding method for power battery case

A power battery and shell technology, applied in the field of laser welding of power battery shells, can solve problems such as high economic cost and waste of resources, and achieve high energy utilization, reduce reflectivity, and smooth and uniform welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

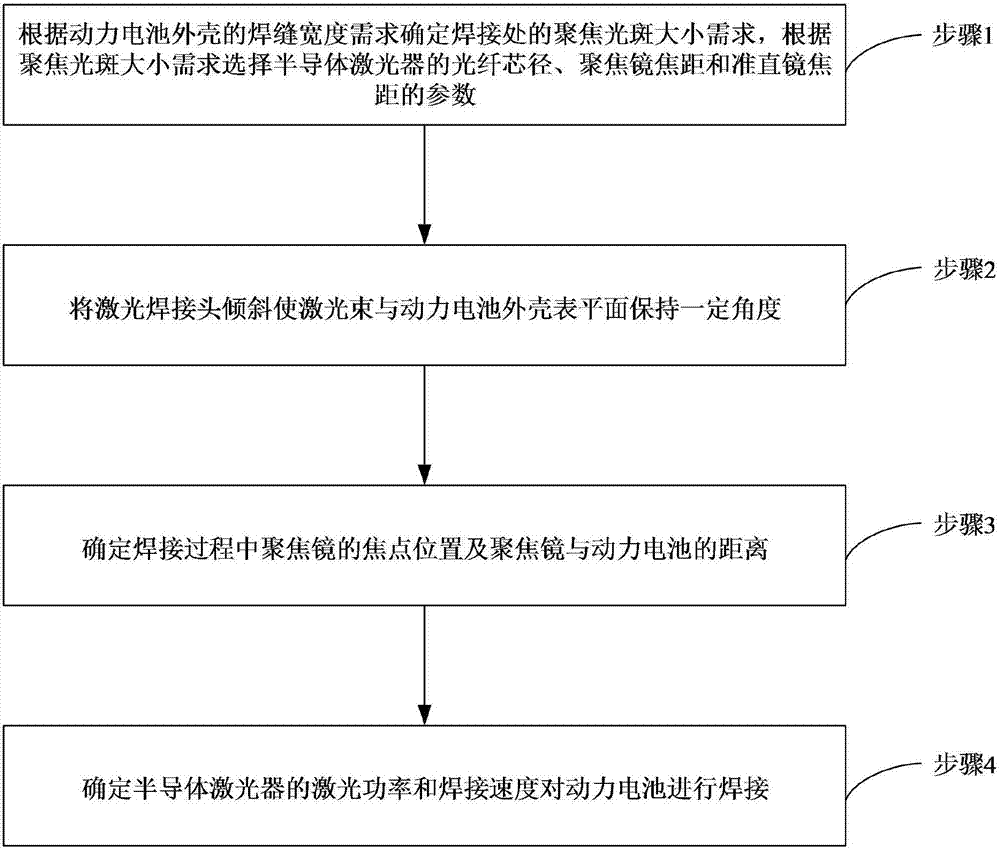

[0024] Embodiments of the laser welding method for the power battery casing provided by the present invention include:

[0025] In the embodiment of the present invention, the semiconductor laser used can be a fiber transmission type or a direct light output type, and the power range can meet the requirements of welding, and 2000w can be selected.

[0026] In the embodiment of the present invention, in step 1, the focus spot size requirement of the welding place is determined according to the weld seam width requirement of the power battery casing, and the fiber core diameter, focus lens focal length and collimator lens focal length of the semiconductor laser are selected according to the focus spot size requirement. :

[0027] The diameter D of the focused light spot is smaller than but close to the width d of the welding seam of the power battery casing, specifically 0.8d≤D<d. The relationship between the diameter D of the focused spot, the core diameter d of the semiconduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com