An ultra-low temperature composite insulation material suitable for liquid gas storage and transportation equipment

A technology for composite thermal insulation materials and transportation equipment, which is applied in the field of thermal insulation materials for ultra-low temperature equipment, can solve problems such as undiscovered application research reports, and achieve the effects of good thermal insulation performance, stable properties and low outgassing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

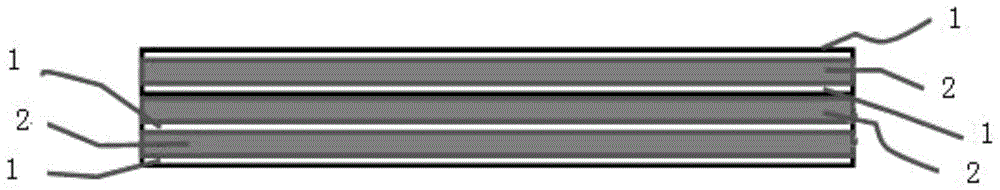

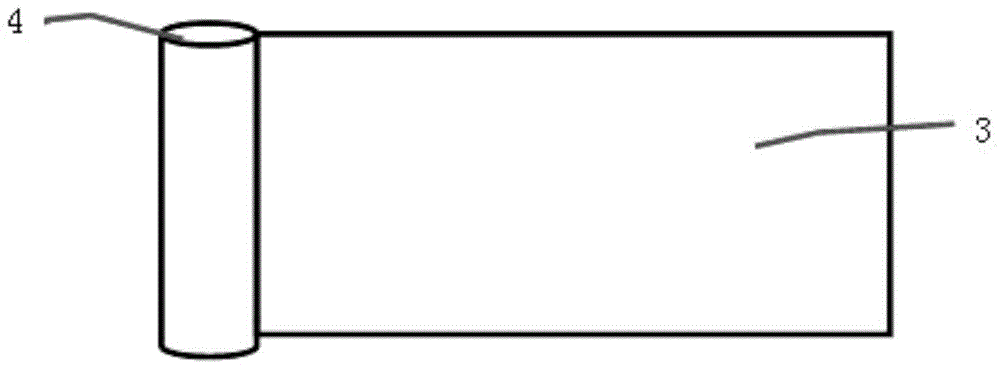

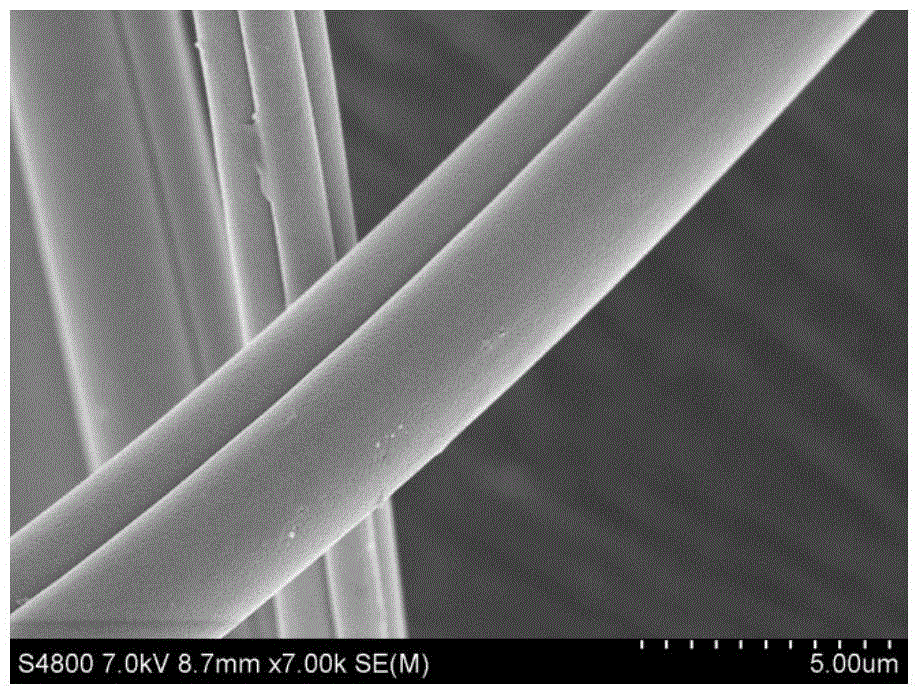

[0032] The monoclinic zirconia fiber cotton is prepared into a felt, the diameter of the zirconia fiber is 0.3-1 μm, the thickness of the felt is 5-6 mm, and the width of the felt is 3000 mm; the zirconia fiber felt and the aluminum foil with a thickness of 6-7 μm are laminated layer by layer. to a total thickness of about 20mm.

[0033] Wrap the compounded material on the inner tank body of the liquid gas storage tank, fix it and put it into the outer tank, and then vacuumize it to 10 -4 Pa, the product can effectively maintain a high vacuum for a long time, and has good low temperature heat insulation and flame retardancy.

[0034] In gas cylinders filled with liquid nitrogen in the liner, the thermal insulation effect of zirconia fiber is 10%-20% higher than that of glass fiber paper. Compared with glass fiber paper, the vacuum outgassing rate is greatly reduced.

Embodiment 2

[0036] As described in Example 1, when the inner tank is loaded with 500L of liquefied natural gas, the thermal insulation effect of the zirconia fiber is 10%-20% higher than that of the glass fiber paper. Compared with glass fiber paper, the vacuum ventilation rate and static evaporation rate are greatly reduced.

Embodiment 3

[0038] (1) Monoclinic zirconia fiber cotton is prepared into a mat, the fiber diameter is 3-4 μm, the thickness of the felt is 4-5 mm, and the width of the felt is 1000 mm; the fiber mat and the aluminum foil with a thickness of 7-8 μm are laminated layer by layer. to a total thickness of about 20mm.

[0039] (2) Wrap the compounded material on the inner tank cylinder, fix it into the outer tank, and vacuumize it to 10 after airtight - 3 Pa, can effectively maintain a high vacuum degree for a long time, and has good low temperature heat insulation and flame retardancy. The inner tank is loaded with liquefied natural gas, and the thermal insulation effect of zirconia fiber composite material is 20% higher than that of glass fiber paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com