Selective Hydrogenation Process of Alkyne-rich C4

A selective hydrogenation and process technology, applied in the purification/separation of hydrocarbons, hydrocarbons, organic chemistry, etc., can solve the problem that the yield of butadiene has not been improved to the greatest extent, so as to reduce the amount of polymer production, The effect of reducing the formation of polymers and reducing the content of alkynes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

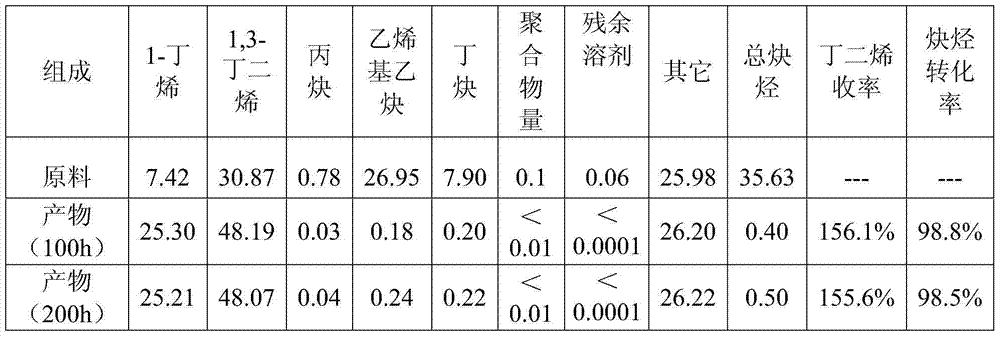

Embodiment 1

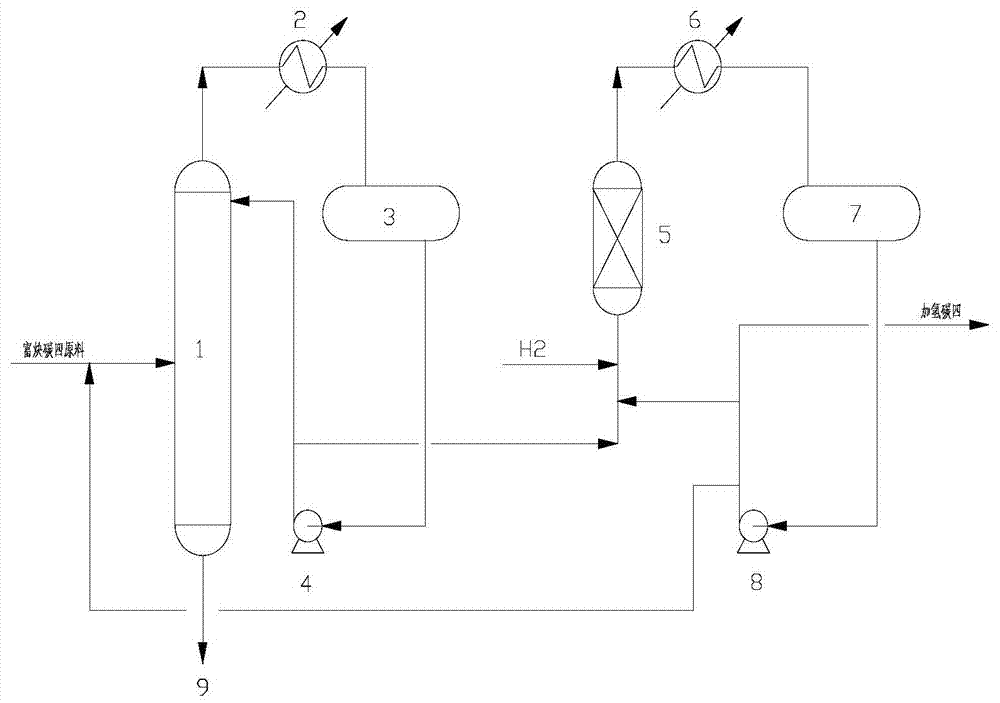

[0043] The following hydrogenation process is selected:

[0044] (1) The C4 material containing alkynes comes out of the extraction device or the tank area, and first enters the rectification tower. The pressure of the rectification tower is controlled at 0.5 MPa, the temperature of the tower top is controlled at 59 ° C, and the temperature of the tower bottom is controlled at 120 ° C. Separating the entrained impurities from C4, C4 is extracted from the top of the tower, condensed by the condenser and enters the reflux tank, and impurities are extracted from the bottom of the tower to the fuel tank;

[0045] (2) C4 is pressurized by the hydrogenation raw material pump, and a part is returned to the rectification tower as a reflux liquid, and the mass ratio of the reflux liquid amount to the discharge amount at the top of the tower is 0.5:1, and the other part is mixed with H 2 Mixed into the hydrogenation reactor, the molar ratio of hydrogen to the total alkyne at the reactor...

Embodiment 2

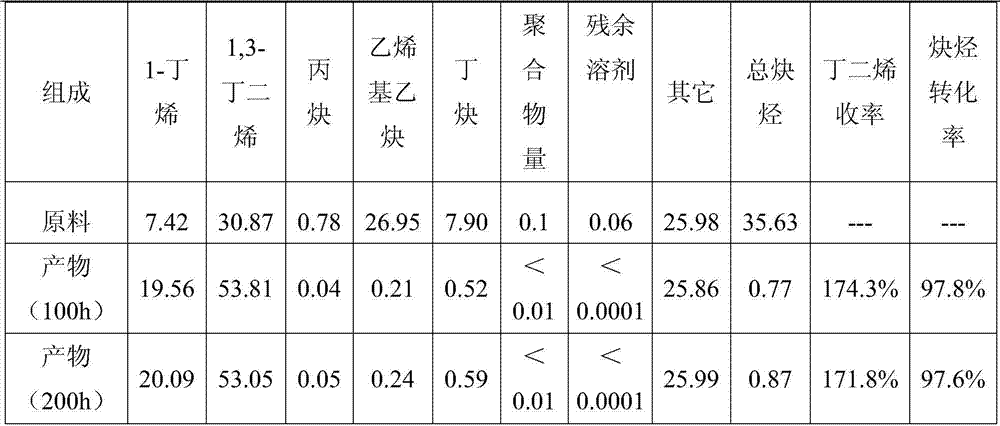

[0053] The feedstock of this embodiment is the raw material rich in alkyne, and the raw material is the same as in Example 1, and the palladium-lead-potassium polymetallic catalyst is loaded into the alkyne hydrogenation reactor, and its content is palladium 0.3wt%, lead 0.5wt%, potassium 0.5wt% %, the catalyst carrier is alumina, the hydrogenation reactor is an adiabatic fixed-bed reactor, the bed inlet is 30°C, the pressure is 1.5MPa, and the liquid space velocity of the high alkyne raw material is 1.0h -1 , the recycle ratio is 14:1, the molar ratio of hydrogen to alkyne is 1.2:1, the ratio of the first hydrogenation material returning to the rectification tower to the high alkyne material entering the tower is 2:1, and the rectification tower reflux ratio is 0.2. Table 2 lists the composition before and after the reaction.

[0054] Material composition before and after table 2 reaction

[0055]

[0056] As can be seen from Table 2, after 200 hours of operation, the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com