Synthetic method of polycarbosilane

A technology of polycarbosilane and synthesis method, which is applied in the field of preparing polycarbosilane, can solve the problems of low yield and poor thermal stability of polycarbosilane synthesis, and achieve the effect of mild conditions and simple post-treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

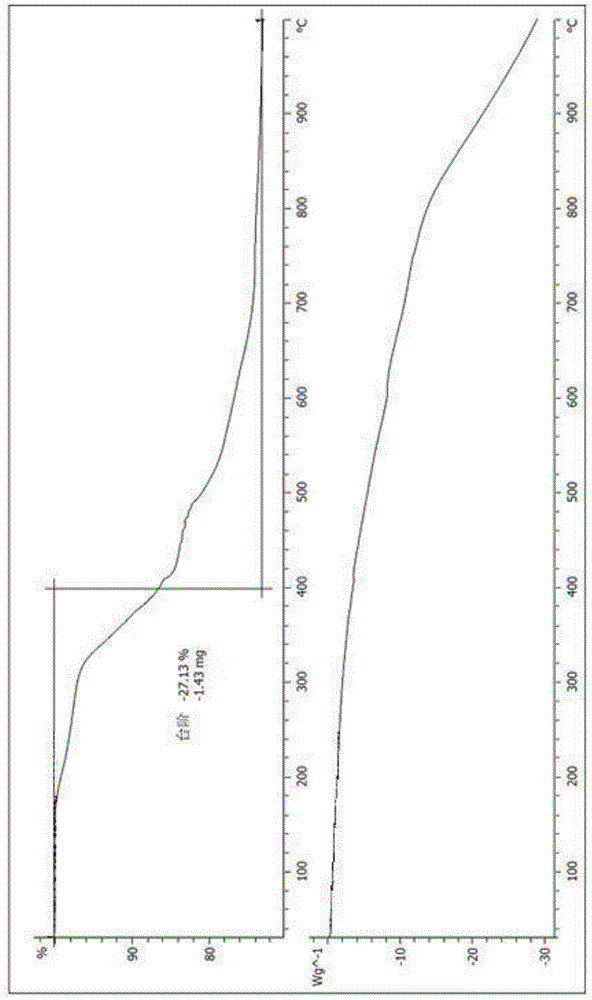

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the synthetic method of a kind of polycarbosilane of this embodiment is carried out according to the following steps:

[0019] 1. In the autoclave, add 50g of polydimethylsilane and 0.5g of 100-200-mesh iron powder, replace the autoclave with carbon dioxide gas 3-6 times, start heating, and raise the temperature to 260°C-270°C within 1 hour, and Keep warm for 3 to 3.5 hours until the pressure in the autoclave is 1MPa, then cool down to 50°C to 60°C, release the gas in the autoclave, and then reheat, within 4 hours to 480°C to 560°C, at a pressure of 4.8 MPa~6MPa, temperature 480℃~560℃, keep warm for 9h~11h, then cool to room temperature;

[0020] 2. Dissolve the reaction product obtained in step 1 in 100ml of xylene, filter to obtain a clear and transparent solution, add 100ml of ethanol solution, and precipitate a brown-yellow solid product to obtain polycarbosilane.

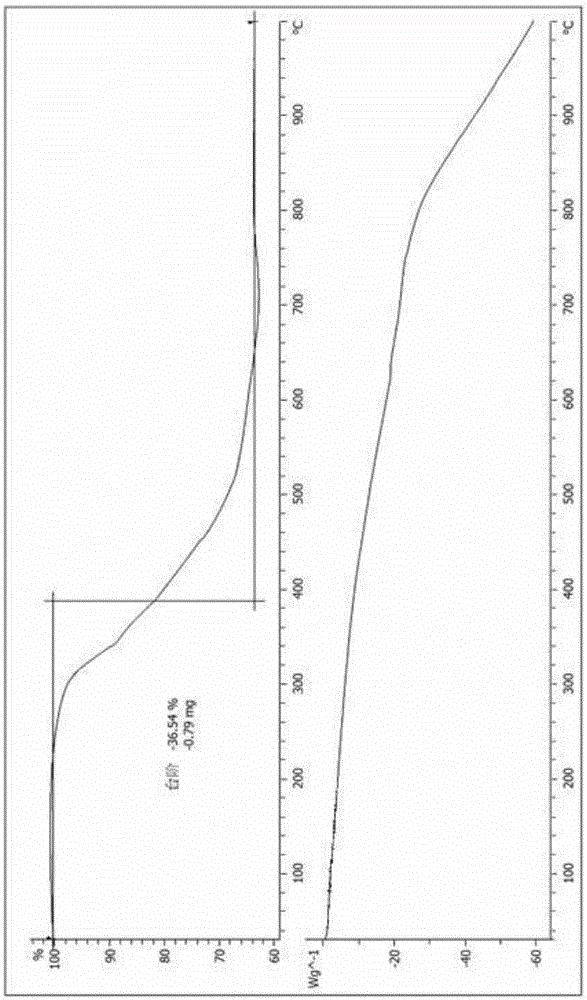

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the temperature is raised to 515° C. within 4 hours. Others are the same as in the first embodiment.

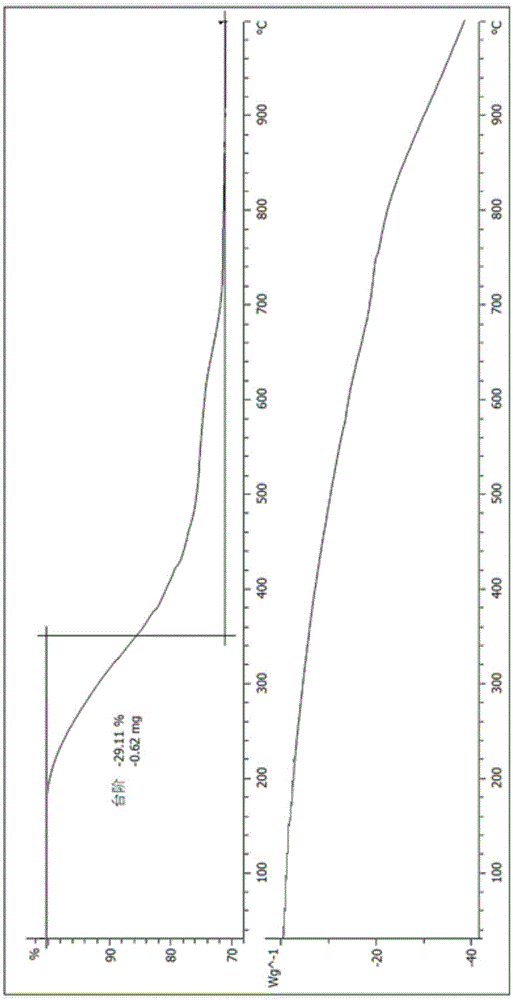

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the temperature is raised to 500° C. within 4 hours. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com