Method for simultaneously preparing long-chain alkane and arene by taking microalgae oil as raw material

A technology of long-chain alkanes and microalgae oil, which is applied in the preparation of biological raw materials, liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of no aromatics, no aromatics, etc., and achieves strong environmental adaptability, high oil content and distribution. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

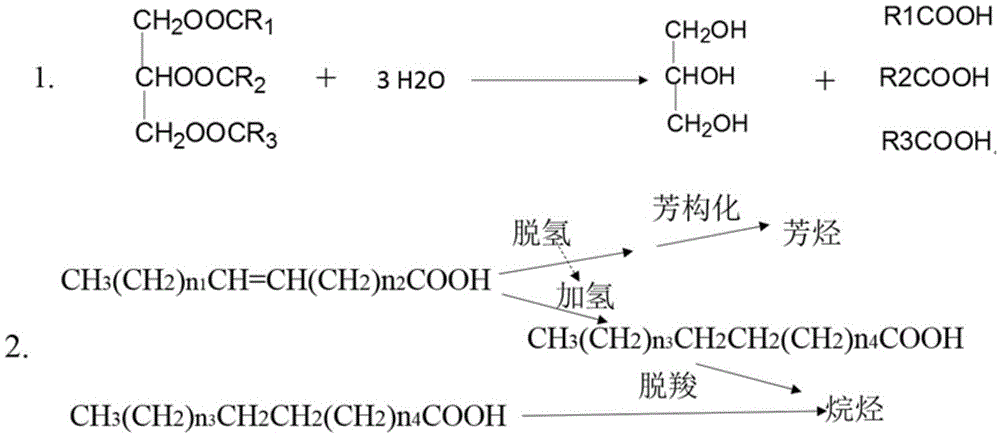

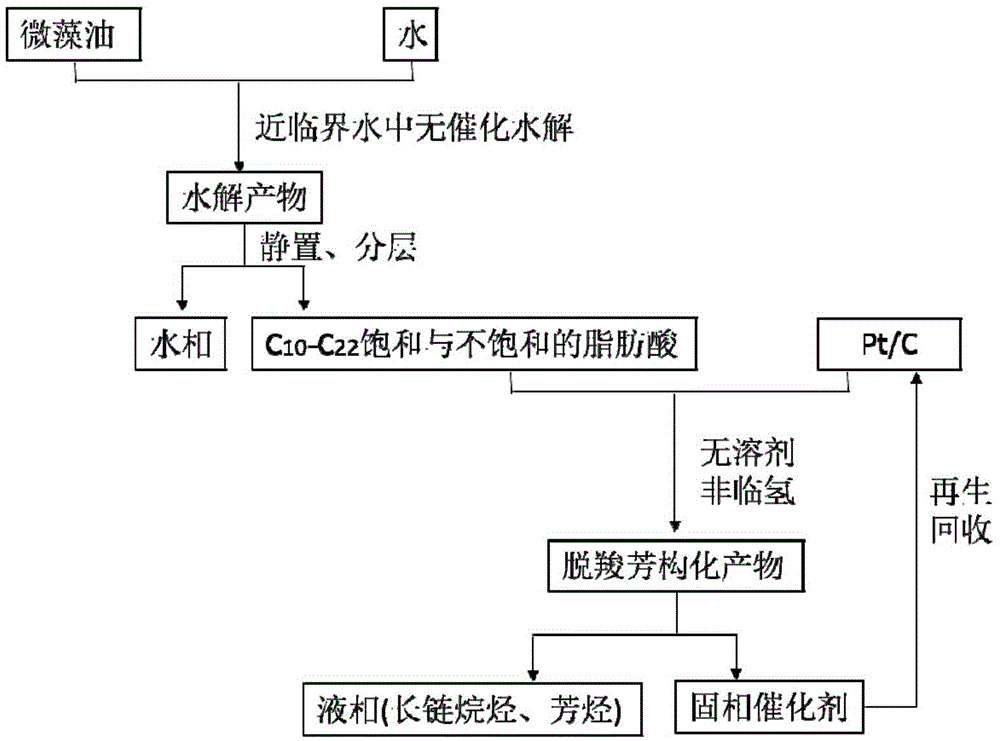

Method used

Image

Examples

Embodiment 1

[0038] Add 100g of microalgae oil and 100g of deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, and heat up to 200°C for 9 hours of hydrolysis reaction. After the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 10 ~C 22 fatty acid) 87.8g; 87.8g of hydrolyzate and 5.2g of Pt / C were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 350°C for 4 hours, and filtered while hot to obtain 52.5g of C 9 ~C 21 Long chain alkanes and 16.6 g aromatics.

Embodiment 2

[0040] Add 100g of microalgae oil and 100g of deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 240 ° C for 7 hours of hydrolysis reaction, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 10 ~C 22 fatty acid) 88.4g; 88.4g of hydrolyzate and 8.8g of Pt / C were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 350°C for 3 hours, and filtered while hot to obtain 54.9g of C 9 ~C 21 Long chain alkanes and 17.4 g aromatics.

Embodiment 3

[0042] Add 100g of microalgae oil and 100g of deionized water into a 500mL intermittent high-temperature and high-pressure reactor, start stirring, heat up to 260°C for hydrolysis reaction for 6h, after the hydrolysis reaction is completed, cool to room temperature, and obtain the upper hydrolyzate (C 10 ~C 22 fatty acid) 90.6g; 90.6g of hydrolyzate and 11.7g of Pt / C were added to a 500mL intermittent high-temperature and high-pressure reactor, heated to 350°C for 2 hours, and filtered while hot to obtain 58.3g of C 9 ~C 21 Long chain alkanes and 17.9 g aromatics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com