Method for improving excess activated sludge anaerobic fermentation hydrogen production efficiency

A technology of sludge anaerobic fermentation and residual activity, applied in the field of resource utilization of organic waste, can solve problems such as insignificant effect, achieve the effect of improving the degree of resource utilization, improving the hydrogen production capacity of fermentation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Concentrate the remaining activated sludge from the sewage treatment plant. The total suspended solids (TSS) of the concentrated sludge is 10.6g / L, and the volatile suspended solids (VSS) is 6.9g / L. No other pretreatment process is required.

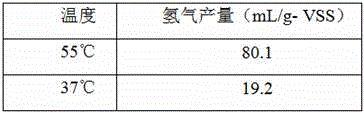

[0014] (2) Divide the concentrated sludge into two 500mL reactors, each reactor is equipped with 400mL concentrated sludge, adjust the initial pH of the sludge in the reactor to 10.06-10.14, and blow off the exhaust gas After the oxygen environment, one reactor was fermented in a shaking table at 37°C, and the other was fermented in a shaking table at 55°C. The fermentation process lasted for 6 days. The control is 10 for alkaline conditions. The content of gas components is determined by a gas chromatograph, and the gas volume is collected by a gas collection bag. After the reactor runs stably, the hydrogen output in the two reactors is as shown in Table 1:

[0015] Table 1 Effect of temperature on alkaline fermentation hyd...

Embodiment 2

[0019] (1) Concentrate the remaining activated sludge from the sewage treatment plant. The total suspended solids (TSS) of the concentrated sludge is 10.6g / L, and the volatile suspended solids (VSS) is 6.9g / L. No other pretreatment process is required.

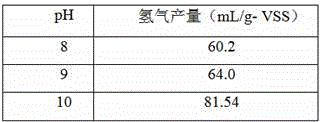

[0020] (2) Divide the concentrated sludge into three 500mL reactors, each reactor is equipped with 400mL concentrated sludge, adjust the initial pH of the sludge in the reactor to 8, 9, 10, and use nitrogen to Air stripping creates an anaerobic environment, and the reactors are placed in a shaking table at 55°C for anaerobic fermentation, and the hydraulic retention time is 6 days. During the fermentation process, 4M NaOH was added dropwise through the pH automatic titrator to always control the sludge in the three reactors to be 8, 9, and 10 respectively. During the operation of the reactor, the gas component content is measured by a gas chromatograph, and the gas volume is collected by a gas collection bag. After the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com