Method for regulating and controlling physical phases of zinc and calcium conversion films on pure-titanium surfaces by aid of pH (potential of hydrogen) value

A technology of conversion coating and pure titanium, which is applied in medical science, metal material coating technology, prosthesis, etc., can solve the problems of no retrieval and no mention of conversion coating, and achieve resource saving, low cost and high conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

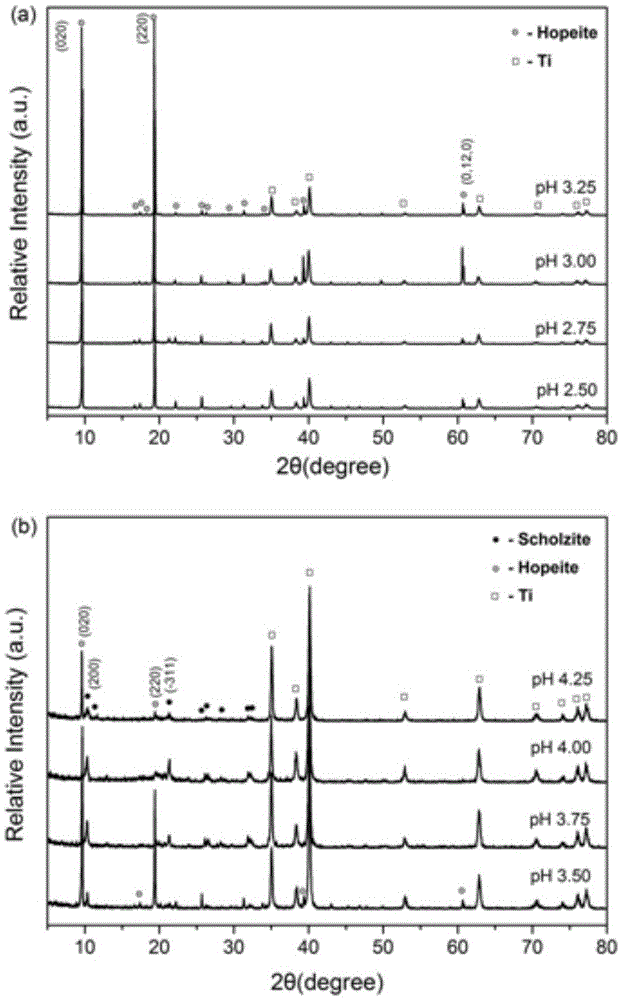

[0026] A method for controlling the phase of the zinc-calcium conversion coating on the surface of pure titanium by using the pH value described in this embodiment, the specific steps are as follows:

[0027] (1) Preparation: the concentration of each component is Zn(H 2 PO 4 ) 2 2H 2 O30g / L, Ca(NO 3 ) 2 4H 2 O12g / L and NaNO 2 2g / L chemical conversion solution.

[0028] (2) Adjust the pH value of the above chemical conversion solution to 2.75 with H3PO4 or NaOH solution.

[0029] (3) At 25°C, treat the polished titanium substrate with 2wt.% HF solution for 15s, then rinse it with deionized water several times, and put it into the colloidal titanium solution for surface adjustment for 30s;

[0030] (4) quickly place the pure titanium substrate treated in step (3) in the chemical conversion solution obtained in step (2), and perform chemical conversion treatment for 30 minutes.

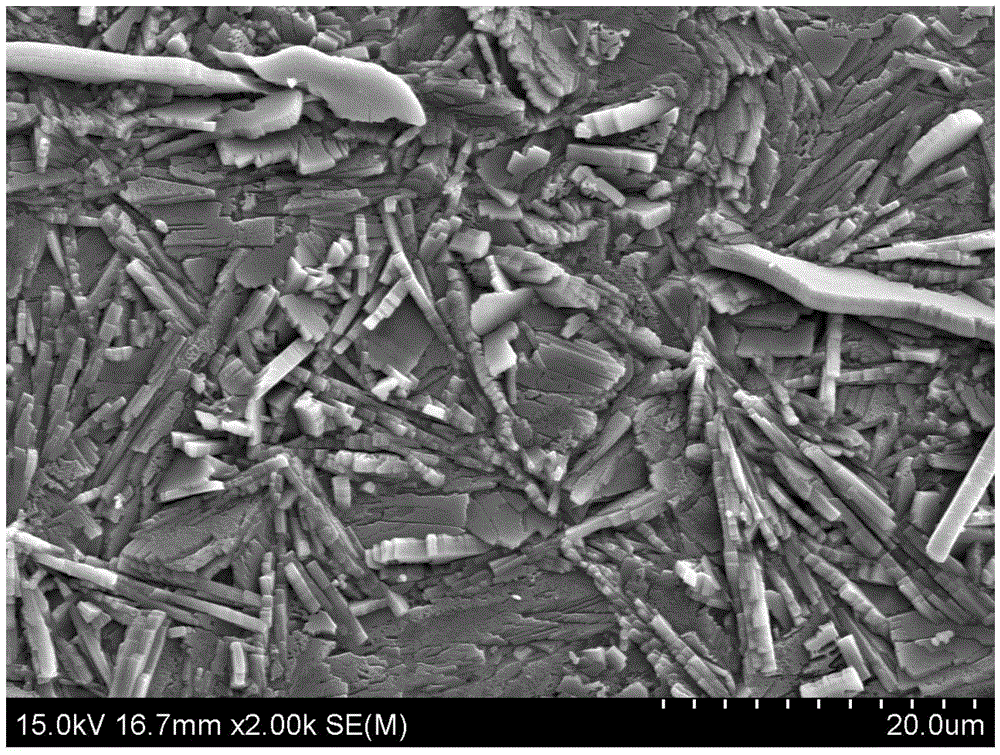

[0031] (5) washing and drying the product obtained in step (4) to obtain a zinc phosphate c...

Embodiment 2

[0033] A method for controlling the phase of the zinc-calcium conversion coating on the surface of pure titanium by using the pH value described in this embodiment, the specific steps are as follows:

[0034] (1) Preparation: the concentration of each component is Zn(H 2 PO 4 ) 2 2H 2 O22g / L, Ca(NO 3 ) 2 4H 2 O8g / L and NaNO 2 1.5g / L chemical conversion fluid.

[0035] (2) with H 3 PO 4 or NaOH solution to adjust the pH value of the chemical conversion solution to 3.50.

[0036] (3) At 25°C, treat the polished titanium substrate with 2wt.% HF solution for 15s, then rinse it with deionized water several times, and put it into the colloidal titanium solution for surface adjustment for 30s;

[0037] (4) quickly place the pure titanium substrate treated in step (3) in the chemical conversion solution obtained in step (2), and perform chemical conversion treatment for 30 minutes.

[0038] (5) The product obtained in step (4) is washed and dried to obtain a zinc phosphate ...

Embodiment 3

[0040] A method for controlling the phase of the zinc-calcium conversion coating on the surface of pure titanium by using the pH value described in this embodiment, the specific steps are as follows:

[0041] (1) Preparation: the concentration of each component is Zn(H 2 PO 4 ) 2 2H 2 O26g / L, Ca(NO 3 ) 2 4H 2 O10g / L and NaNO 2 2g / L chemical conversion solution.

[0042] (2) with H 3 PO 4 or NaOH solution to adjust the pH value of the chemical conversion solution to 4.50.

[0043] (3) At 25°C, treat the polished titanium substrate with 2wt.% HF solution for 15s, then rinse it with deionized water several times, and put it into the colloidal titanium solution for surface adjustment for 30s;

[0044] (4) quickly place the pure titanium substrate treated in step (3) in the chemical conversion solution obtained in step (2), and perform chemical conversion treatment for 30 minutes.

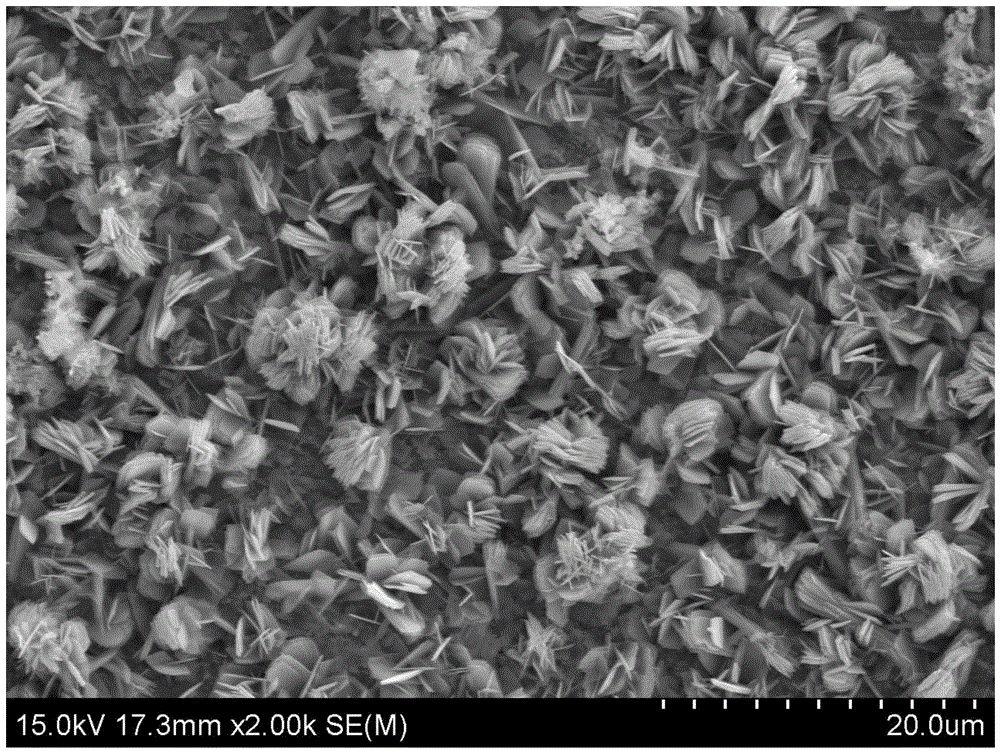

[0045] (5) washing and drying the product obtained in step (4) to obtain a zinc-calcium pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com