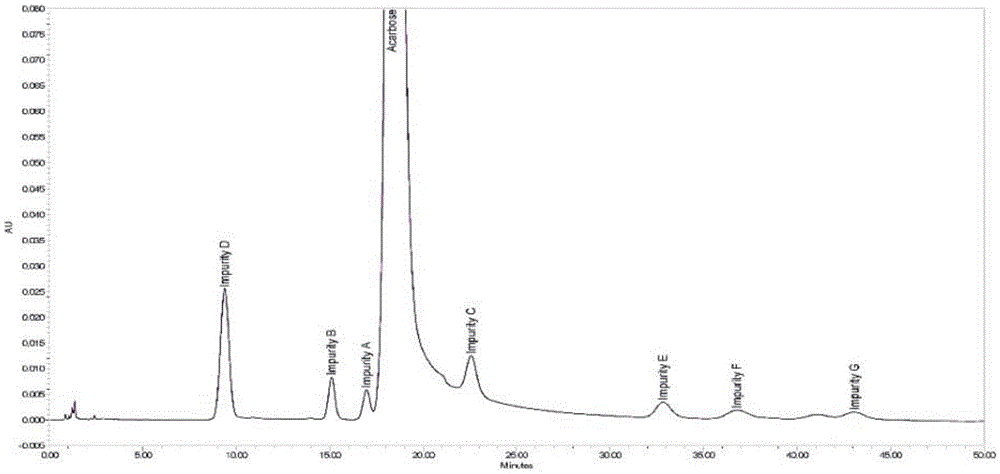

Method for detecting acarbose through high performance liquid chromatography

A high-performance liquid chromatography and acarbose technology, which is applied in the field of high-performance liquid chromatography to detect acarbose, can solve the problems of inconvenient analysis work, long running time, column loss and the like, and achieves simple mobile phase preparation, Realize the effect of quality control and good quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 1 Preparation of solution

[0078] 1.1 Spare buffer solution and mobile phase

[0079] 200mM ammonium formate buffer salt (pH3.0): Weigh 12.6g of ammonium formate into a 1L volumetric flask, add appropriate amount of water to dissolve, add 25mL of formic acid, mix well, add water to make up to the mark.

[0080] 200mM ammonium acetate buffer salt (pH6.8): Weigh 15.4g of ammonium acetate into a 1L volumetric flask, add water to dissolve to volume.

[0081] 200mM ammonium acetate buffer salt (pH9.0): Weigh 15.4g of ammonium acetate into a 1L volumetric flask, add appropriate amount of water to dissolve, add 8mL of ammonia water, mix well, add water to make up to the mark.

[0082] Each mobile phase is obtained by diluting the corresponding backup buffer solution in proportion with 75% acetonitrile water. For example, to prepare 1L of mobile phase containing 10mM ammonium acetate (pH9.0), add 50mL of 200mM ammonium acetate buffer salt (pH9.0) to 750mL of acetonitrile and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com