A method for making external electrodes of electronic components

A technology for electronic components and external electrodes, applied in the field of external electrodes for making electronic components, can solve the problems of environmental pollution, dissatisfaction, time-consuming and material costs, etc., and achieve simple process maintenance, easy operation, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] A method for plasma treatment of the surface of a multi-terminal component, comprising the following steps:

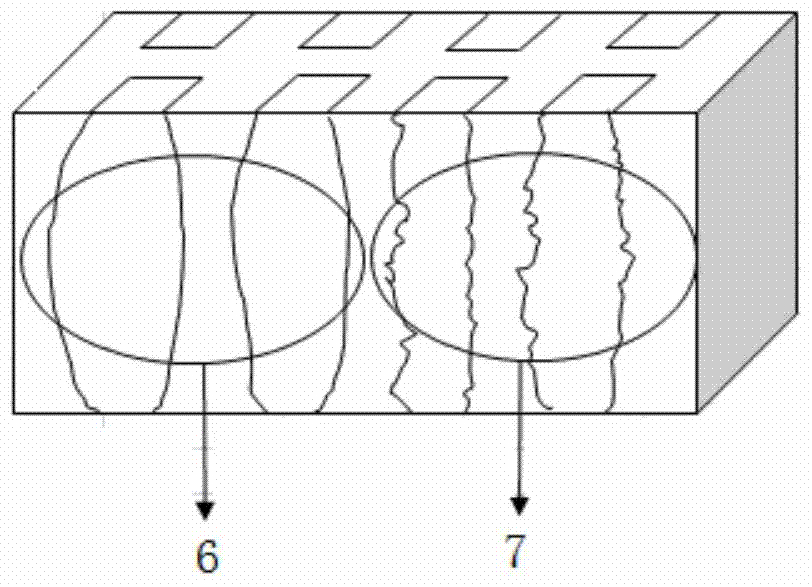

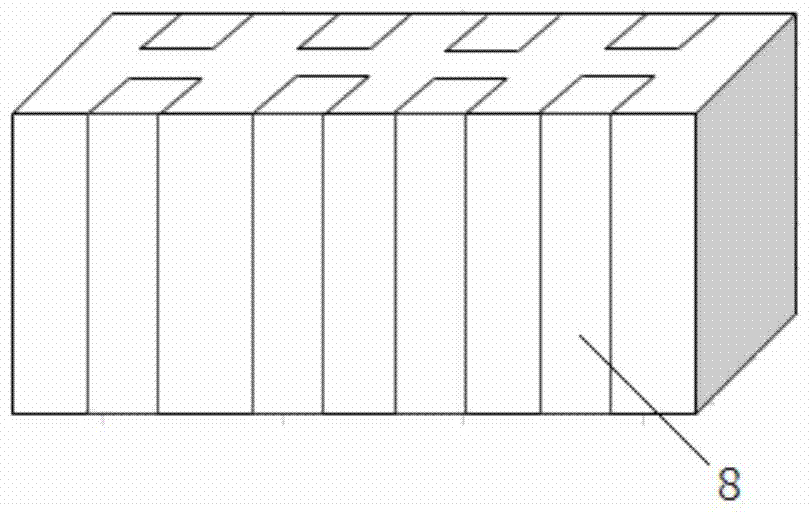

[0049] Step 1: Prefabricated target

[0050] The target is made of iron material into a rectangular box shape, the width and height of the box are 40cm, and the length of the box is made or segmented according to needs;

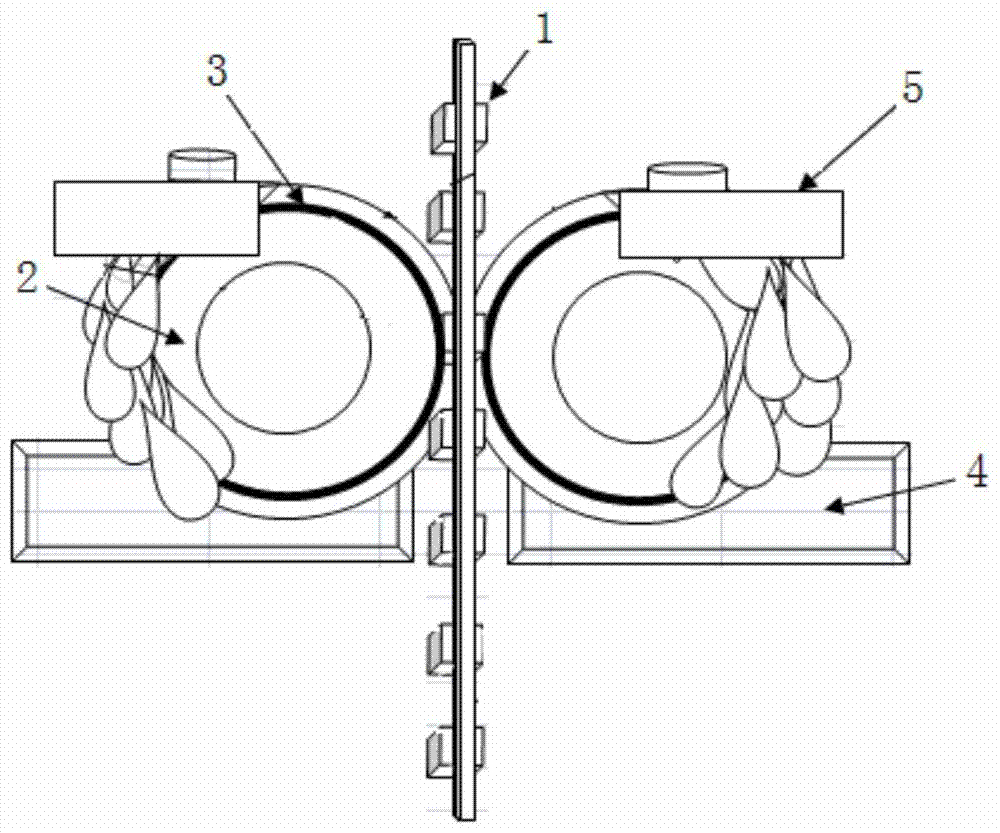

[0051] Step 2: Assembly

[0052] Place the multi-terminal chip components on the upper surface of the conveyor belt and pass through the middle of the target without contacting the target. The conveyor belt shaft is located at both ends of the target, and the target is placed in a vacuum chamber. The target, multi-terminal chip components and The conveyor belts are all insulated from the vacuum chamber;

[0053] Step 3: Load the monomer, ventilate, and power on

[0054] Load monomer HMDSO (hexamethyldisiloxane), feed argon as the carrier, set the target to negative potential, voltage -2600V; adjust the transmission shaft to keep the conveyor...

example 2

[0058] A method for plasma treatment of the surface of a multi-terminal component, comprising the following steps:

[0059] Step 1: Prefabricated target

[0060] The target is made of copper material into a rectangular box shape, the width and height of the box are 10cm, and the length of the box is made or segmented according to needs;

[0061] Step 2: Assembly

[0062] Place the multi-terminal chip components on the upper surface of the conveyor belt and pass through the middle of the target without contacting the target. The conveyor belt shaft is located at both ends of the target, and the target is placed in a vacuum chamber. The target, multi-terminal chip components and The conveyor belts are all insulated from the vacuum chamber;

[0063] Step 3: Load the monomer, ventilate, and power on

[0064] Load monomer HMDSO (hexamethyldisiloxane), feed argon as the carrier, set the target to negative potential, voltage -1000V; adjust the transmission shaft to keep the convey...

example 3

[0068] A method for plasma treatment of the surface of a multi-terminal component, comprising the following steps:

[0069] Step 1: Prefabricated target

[0070] The target is made of iron material into a rectangular box shape, the width and height of the box are 25cm, and the length of the box is made or segmented according to needs;

[0071] Step 2: Assembly

[0072] Place the multi-terminal chip components on the upper surface of the conveyor belt and pass through the middle of the target without contacting the target. The conveyor belt shaft is located at both ends of the target, and the target is placed in a vacuum chamber. The target, multi-terminal chip components and The conveyor belts are all insulated from the vacuum chamber;

[0073] Step 3: Load the monomer, ventilate, and power on

[0074] Load monomer HMDSO (hexamethyldisiloxane), feed argon as the carrier, set the target to negative potential, voltage -1800V; adjust the transmission shaft to keep the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com