Catalyst used for producing olefin through low-carbon alkane dehydrogenation, and preparation method thereof

A technology for low-carbon alkanes and catalysts, applied in the field of catalysts and their preparation, can solve problems such as poor stability and low activity of low-carbon alkanes dehydrogenation catalysts, and achieve the effects of reducing surface acidity, good catalyst performance, and improving anti-sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

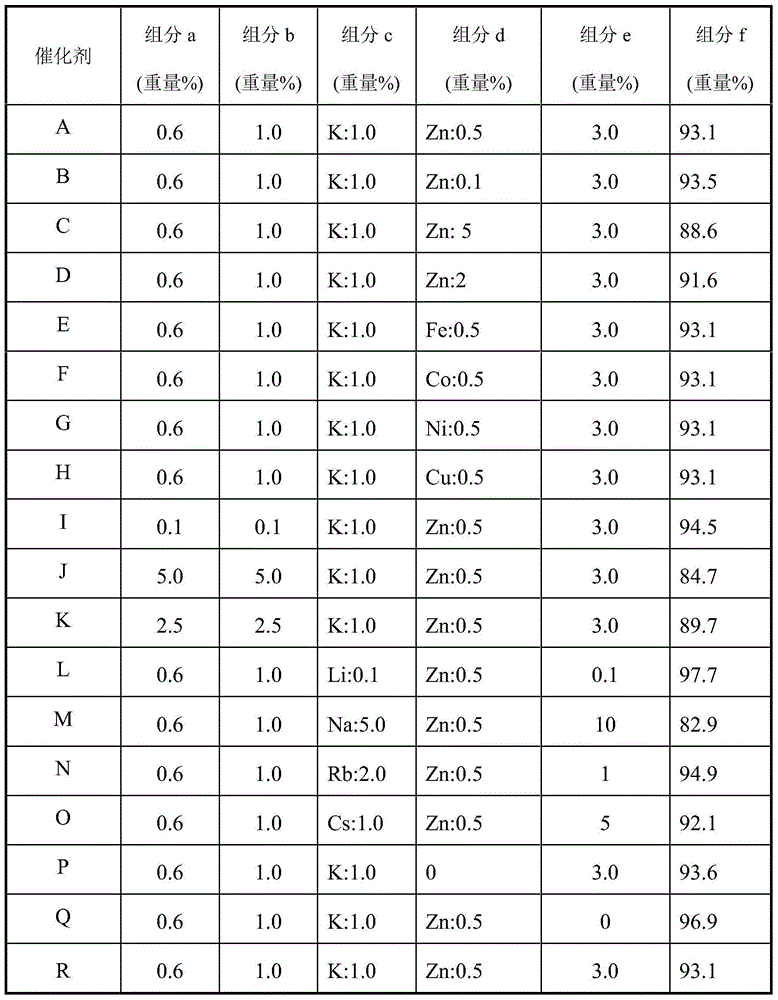

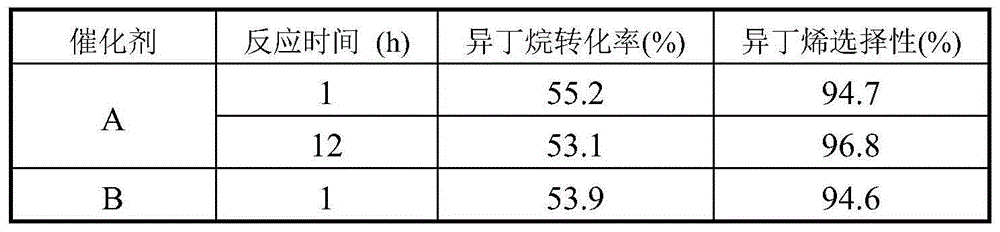

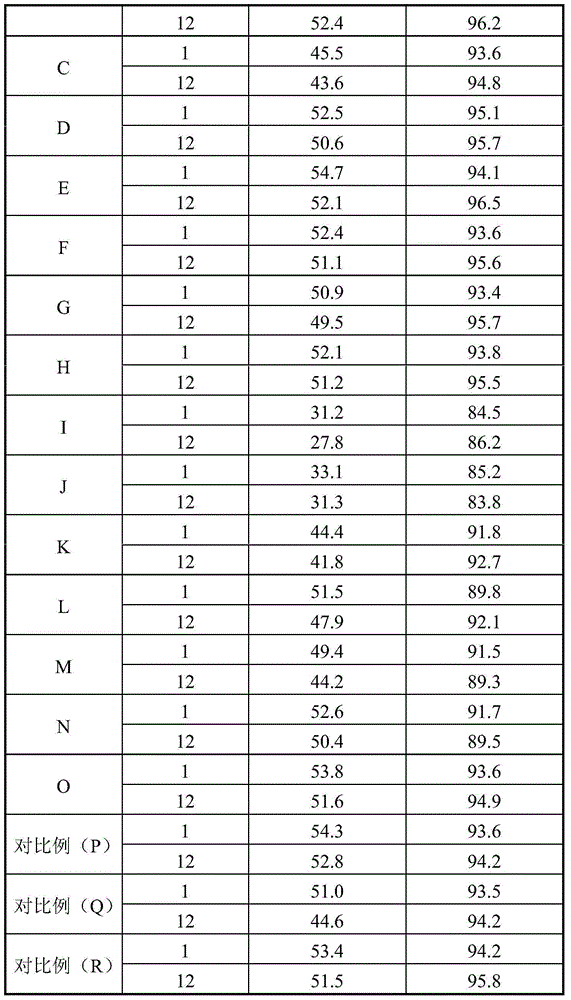

[0024] Weigh 9.39g of alumina carrier and pour it into 200mL of deionized water and stir for 1 hour, then weigh 0.773g of cerium ammonium nitrate and 0.115g of lanthanum nitrate and dissolve them in 50mL of deionized water respectively, then mix the two evenly, pour alumina and In the mixed solution of water, after continuing to stir for 1 hour, ammonia water was slowly added dropwise under continuous stirring until the pH was 8.5. Aging the product for 2 hours, filtering and washing with 2L of water to obtain a filter cake, drying the filter cake at 90°C for 16 hours, and then roasting it in a muffle furnace at 580°C for 20 hours to obtain Ce 0.8 La 0.2 o 2-δ -Al 2 o 3carrier, here La will make CeO 2 Oxygen vacancies are generated, and δ is the non-stoichiometric value of oxygen (the same below). Weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add it to the above-mentioned carrier under stirring, mix well, soak at 30°C for 12 hour...

Embodiment 2

[0026] Weigh 9.43g of alumina carrier and pour it into 200mL of deionized water and stir for 1 hour, weigh 0.773g of cerium ammonium nitrate and 0.115g of lanthanum nitrate and dissolve them in 50mL of deionized water respectively, then mix the two evenly, pour into alumina and In the mixed solution of water, after continuing to stir for 1 hour, ammonia water was slowly added dropwise under continuous stirring until the pH was 8.5. The product was aged for 2 hours, filtered and washed with 2L of water to obtain a filter cake, dried at 90°C for 16 hours, and then calcined in a muffle furnace at 580°C for 20 hours to obtain Ce 0.8 La 0.2 o 2-δ -Al 2 o 3 carrier. Weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add it to the above-mentioned carrier under stirring, mix well, soak at 30°C for 12 hours, and then dry at 90°C for 16 hours to obtain the catalyst precursor, which is recorded as I. Weigh 0.159g of chloroplatinic acid, 0.259g o...

Embodiment 3

[0028] Weigh 8.94g of alumina carrier and pour it into 200mL of deionized water and stir for 1 hour, weigh 0.773g of cerium ammonium nitrate and 0.115g of lanthanum nitrate and dissolve them in 50mL of deionized water respectively, then mix the two evenly, pour into alumina and In the mixed solution of water, after continuing to stir for 1 hour, ammonia water was slowly added dropwise under continuous stirring until the pH was 8.5. The product was aged for 2 hours, filtered and washed with 2L of water to obtain a filter cake, dried at 90°C for 16 hours, and then calcined in a muffle furnace at 580°C for 20 hours to obtain Ce 0.8 La 0.2 o 2-δ -Al 2 o 3 carrier. Weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add it to the above-mentioned carrier under stirring, mix well, soak at 30°C for 12 hours, and then dry at 90°C for 16 hours to obtain the catalyst precursor, which is recorded as I. Weigh 0.159g of chloroplatinic acid, 0.259g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com