A multifunctional curtain for water purification

A water purification and multi-functional technology, applied in the direction of water/sewage multi-stage treatment, water pollutants, metallurgical wastewater treatment, etc., can solve multiple complex pollution and other problems, achieve flexible application forms, reduce the generation of secondary pollutants, The effect of long-term stable and high-efficiency water purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

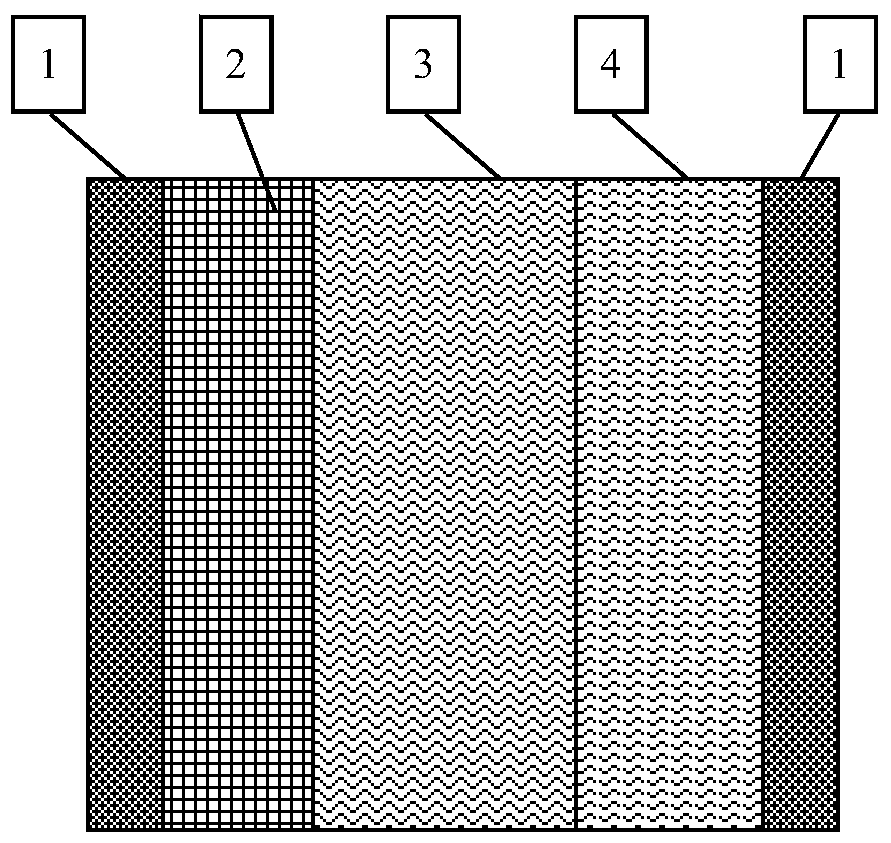

[0038] Such as figure 1The layer-by-layer water purification multi-functional curtain structure shown is composed of: polyester long fiber industrial filter cloth 240 (60-10) is woven with multifilament plain weave, and the weight is 240 g / square meter; the density is 22 / cm, Weft 18.8 / cm, strength N / 5*20cm radial 2162.6, weft 1082.6, elongation 32.03 longitude, weft 24.87, air permeability 36.1 liters / square meter per second, thickness 0.42 mm, used on both sides of the periphery ;Ordinary commercially available industrial polyurethane filter sponge, with a porosity of 96%, a pore size of 30PPI, and a density of 28kg / m 3 , 2 layers side by side, each layer thickness 20 mm; a company produces TK-1500 activated carbon fiber felt, with a specific surface area of 1400 m 2 / g, benzene adsorption value 50%, iodine adsorption value 1400mg / g, methylene blue adsorption value 220mg / g, ash content ≤ 4, average pore diameter 18~21 angstroms, carbon content 70~95%, 10 layers in parallel...

Embodiment 2

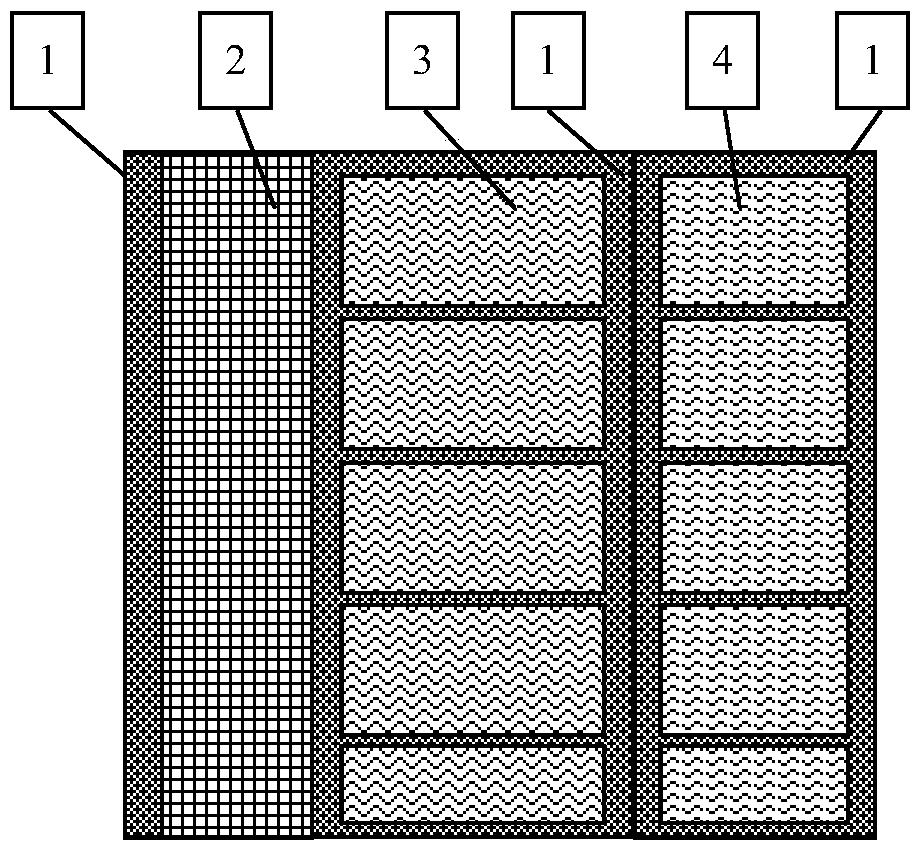

[0041] Such as figure 2 The layered bag side-by-side water purification multifunctional curtain structure shown is mainly composed of filter cloth, activated carbon fiber, and ion exchange fiber, including polyester long fiber industrial filter cloth 240 (60-10), which is woven with multifilament plain weave and weighs 240 grams per square meter; density of warp 22 / cm, weft 18.8 / cm, strength N / 5*20cm radial 2162.6, weft 1082.6, elongation 32.03 longitude, weft 24.87, air permeability 36.1 liters / square meter per second, thickness 0.42 mm; a company produces TK-1500 activated carbon fiber felt with a specific surface area of 1400 m 2 / g, benzene adsorption value 50%, iodine adsorption value 1400mg / g, methylene blue adsorption value 220mg / g, ash content ≤ 4, average pore diameter 18~21 angstroms, carbon content 70~95%, 10 layers in parallel, each layer thickness 15 mm; industrial strong acid cation exchange fiber produced by a certain company, light yellow, SO 3 H-functiona...

Embodiment 3

[0044] Such as figure 2 The layered bag side-by-side water purification multifunctional curtain structure shown is made of the following materials: nylon fiber filter cloth 7239 is woven with nylon multifilament twill, the weight is 470 g / square meter; the density is 37.8 / cm for warp and 18.9 / cm for weft , thickness 0.69mm, strength N / 5*20cm radial 5043.4 weft 3326, elongation 53.6 warp, weft 39.07, breathable 62.85 liters / square meter per second. Pitch-based activated carbon fibers with a specific surface area of 2000 m 2 / g, pore volume 1.1mL / g, constituent element 13μm fiber, bagging thickness 300mm, packing density 40kg / m 3 ;Do not use high-strength porous sponge and ion exchange fiber.

[0045] The raw water to be treated is the advanced treatment of the effluent from the secondary sedimentation tank after the biochemical treatment unit of an urban sewage treatment plant. The influent water quality indicators are COD 100 mg / L, BOD 5 30 mg / L, SS 30 mg / L, NH 3 -N 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com