Method for producing lime based on waste marble powder

A technology for discarding marble and marble powder, applied in lime production and other directions, can solve the problems of failing to meet the quality requirements of white ash in steelmaking, large pollution of lime kiln, low output, etc., saving process time, uniform temperature in the furnace, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

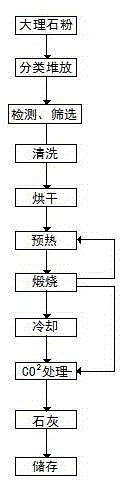

[0029] Example: such as figure 1 As shown, the present invention provides a method for producing lime based on waste marble powder. The waste marble powder is classified and collected, stored in a stacking shed, detected and screened, and then the qualified marble powder after screening and detection is cleaned. After drying, the marble powder is sent to the calcination equipment for calcination, and the marble powder is decomposed into CaO and CO by calcination equipment. 2 , during calcination and collect waste heat to preheat the marble powder that has not yet been calcined, the lime generated after decomposition is cooled by a cooler, and then the CO with temperature generated during calcination 2 The cooled lime is processed and finally stored in the lime storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com