Propylene oxide refining method

A technology of propylene oxide and purification method, applied in the direction of organic chemistry, etc., can solve the problems of difficult separation, low purity of propylene oxide products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

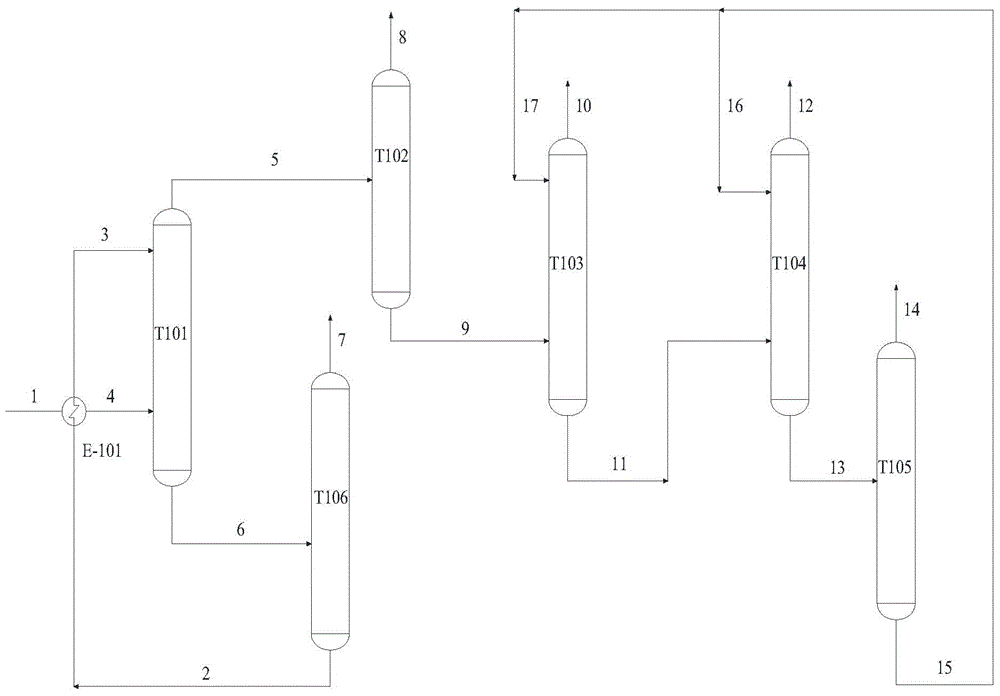

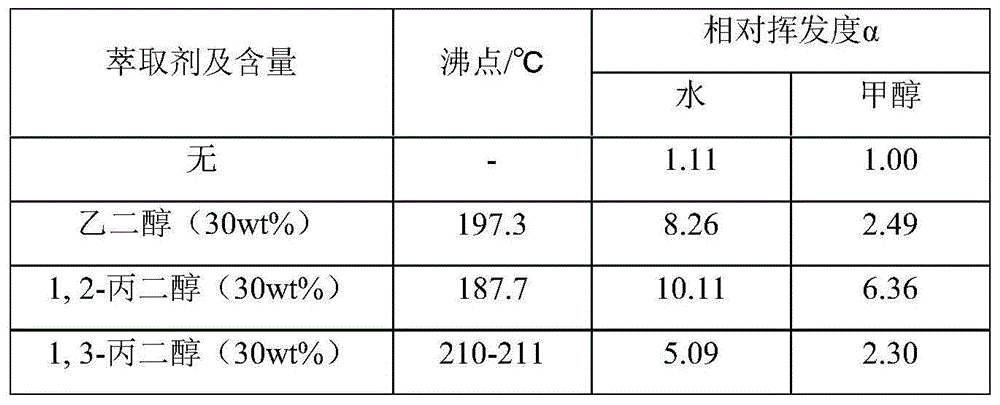

Method used

Image

Examples

Embodiment 1

[0042] Contains water, propylene, propane, acetaldehyde, propionaldehyde, acetone, 2-methylpentane, 2-methylpentene, 3-methylhexane, methylcyclopentane, 1,5-hexadiene, etc. Hydrocarbon impurity stream 2 crude propylene oxide is fed from the lower part of T101 tower, the flow rate of stream 2 is 10t / h, stream 1 extractant propylene glycol is fed from the upper part of T101 tower, and the extractant and crude propylene oxide are countercurrently contacted in the tower , T101 tower theoretical plate number 52, the ratio of the feed mass flow rate of extractant propylene glycol and crude propylene oxide is 1:2.5, operating pressure is controlled at 140kPa, reflux ratio 1.5;

[0043] The composition and content of stream 2 (crude propylene oxide) are as follows:

[0044] Table 1 Crude propylene oxide composition and content

[0045] composition

[0046] T101 tower bottom liquid 4 enters T102 to recover extraction agent propylene glycol, T102 tower bottom liquid 5 is pres...

Embodiment 2

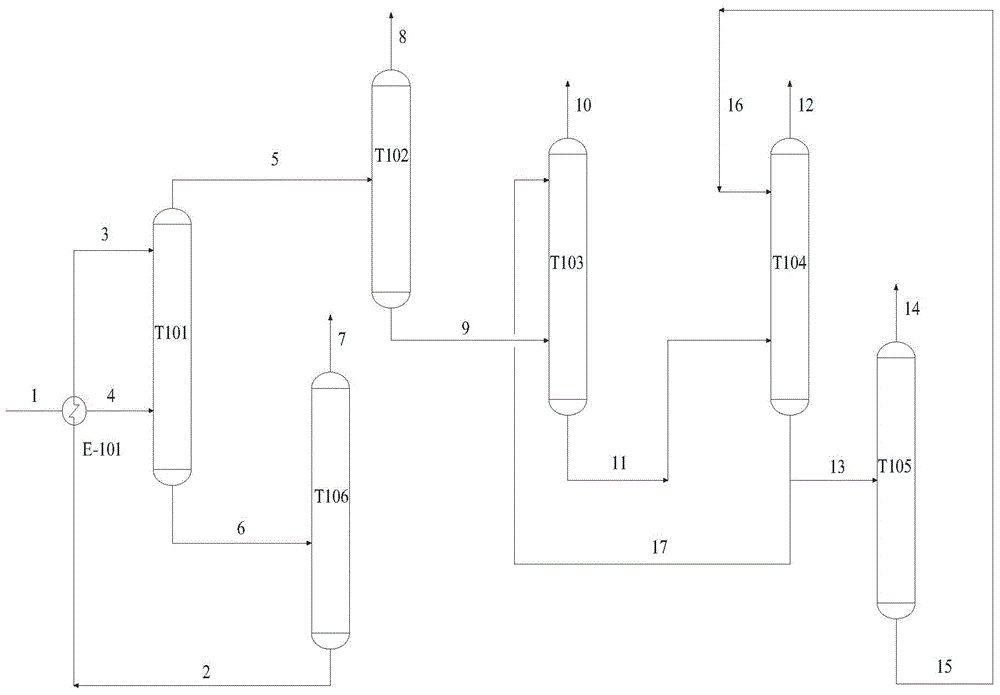

[0055] process such as figure 2 As shown, the T104 tower still liquid is divided into 3 parts, and stream I (15%) is directly recycled to the ethylbenzene peroxidation unit as a reaction raw material (not marked in the figure), stream II (25%) goes to T105 tower, stream III (60 %) to T103 tower as extractant.

[0056] T105 tower has 30 theoretical plates, operating pressure of 120kPa, reflux ratio of 400, and energy consumption of 30% of that of Example 1.

[0057] Propylene oxide content ≥ 99.9wt% in logistics 15, total aldehyde (calculated as propionaldehyde + acetaldehyde) 10mg / kg, hydrocarbon impurity less than 5ppm, water 1ppm, impurity content such as acetone is negligible, propylene oxide recovery rate Reached 99.5%.

[0058] As can be seen from the above, the implementation of the present invention can separate and obtain the polymer grade propylene oxide qualified product in an economical and convenient manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com