Multifunctional amphiphilic terpolymer as well as preparation method and application thereof

A terpolymer and amphiphilic technology, applied in the field of multifunctional amphiphilic terpolymer and its preparation, can solve the problems of PES ultrafiltration membrane fouling and other problems, achieve novel structure, expand application fields, and prolong use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example is used to prepare the multifunctional amphiphilic terpolymer provided by the present invention.

[0038] 2.0ml MMA (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), 2.8ml 4-VPy (purchased from Sigma-Aldrich Company), 5.3ml PEGMA (m=8, (purchased from Sigma-Aldrich Company) was dissolved in 25.0ml of DMF, then 51.9mgAIBN (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.) was added to the mixture, stirred evenly, and then bubbled with argon for 30min (deoxygenation), bubbling After completion, the reaction bottle was sealed and placed in an oil bath at 75°C for 24 hours. Then the reaction solution was precipitated in ether, filtered with suction and washed to remove unreacted monomer, initiator and solvent. The product was dried under vacuum at 70° C. for 24 h to finally obtain 8.5 g of solid with a yield of 84.2%.

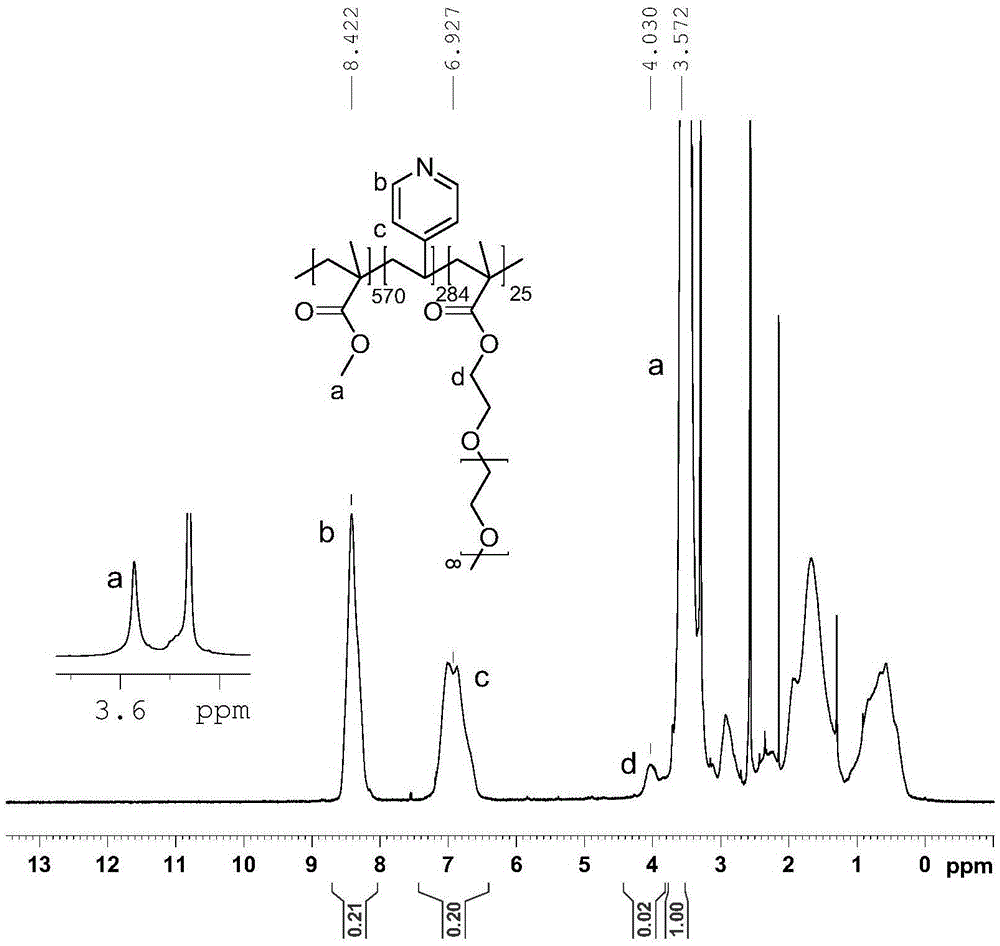

[0039] According to the product 1 As a result of the HNMR test, the product has absorption peaks at δ=3.57...

Embodiment 2

[0044] This example is used to prepare the multifunctional amphiphilic terpolymer provided by the present invention.

[0045] 2ml MMA (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), 4.8ml 4-VPy (purchased from Sigma-Aldrich Company), 4.4ml PEGMA (m=8, (purchased from Sigma-Aldrich Company) was dissolved in 30ml of DMAc, and then 49.6mgAIBN (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.) was added to the mixture, stirred evenly and then bubbled with argon for 20min (deoxygenation), and the bubbling was completed Finally, the reaction bottle was sealed and placed in an oil bath at 65°C for 32 hours. Then, the reaction solution was precipitated in methanol, suction filtered and washed to remove unreacted monomers, initiators and solvents. The product was dried under vacuum at 60° C. for 32 h to finally obtain 9.3 g of solid with a yield of 83%.

[0046] According to the product 1 As a result of the HNMR test, the product has absorption p...

Embodiment 3

[0050] This example is used to prepare the multifunctional amphiphilic terpolymer provided by the present invention.

[0051] 3.5ml MMA (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), 2ml4-VPy (purchased from Sigma-Aldrich Company), 6.8ml PEGMA (m=8, (purchased from Sigma-Aldrich Company) was dissolved in 35ml of DMSO, and then 31.2mgAIBN (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.) was added to the mixture, stirred evenly and then bubbled with argon for 25min (deoxygenation), and the bubbling was completed Finally, the reaction bottle was sealed and placed in an oil bath at 70°C for 28 hours. Then the reaction solution was precipitated in ether, filtered with suction and washed to remove unreacted monomer, initiator and solvent. The product was dried under vacuum at 65° C. for 28 h, and finally 10.6 g of solid was obtained with a yield of 86.2%.

[0052] According to the product 1 As a result of HNMR testing, the product has absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com