Preparation of flexible photonic crystal material with infrared stealth capacity

A technology of photonic crystals and stealth materials, applied in optics, optical components, instruments, etc., can solve problems such as poor mechanical strength, inflexibility, and restrictions on photonic crystals, and achieve the effect of solving practical problems and flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

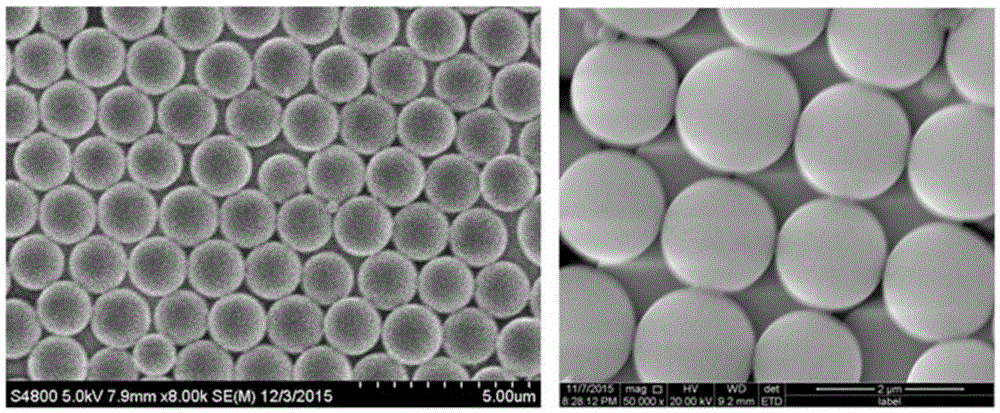

[0013] Example 1 0.5μm monodisperse SiO 2 Microspheres, dispersed in ethanol, controlled SiO 2 The concentration of the microspheres was 1 mg / ml, and they were assembled by the vertical deposition method at room temperature for 2 days to obtain SiO 2 Photonic crystal film. Take 0.5 mL of methacrylic acid, 50 μL of ethylene glycol dimethacrylate (EGDMA) and 1 mL of methanol and mix well, add 10 mg of azobisisoheptanonitrile (ADVN) as a photoinitiator, sonicate for 10 minutes and blow nitrogen for 5 minutes. Clamp the prepared silica photonic crystal template with the plexiglass plate, and immerse it in the above-mentioned pre-polymerization solution. The pre-polymerization solution will absorb the colloidal crystal template through capillary action until the template becomes transparent, and then place it in an ultraviolet incubator for 4 °C for 2 hours to obtain a flexible photonic crystal gel material.

example 2

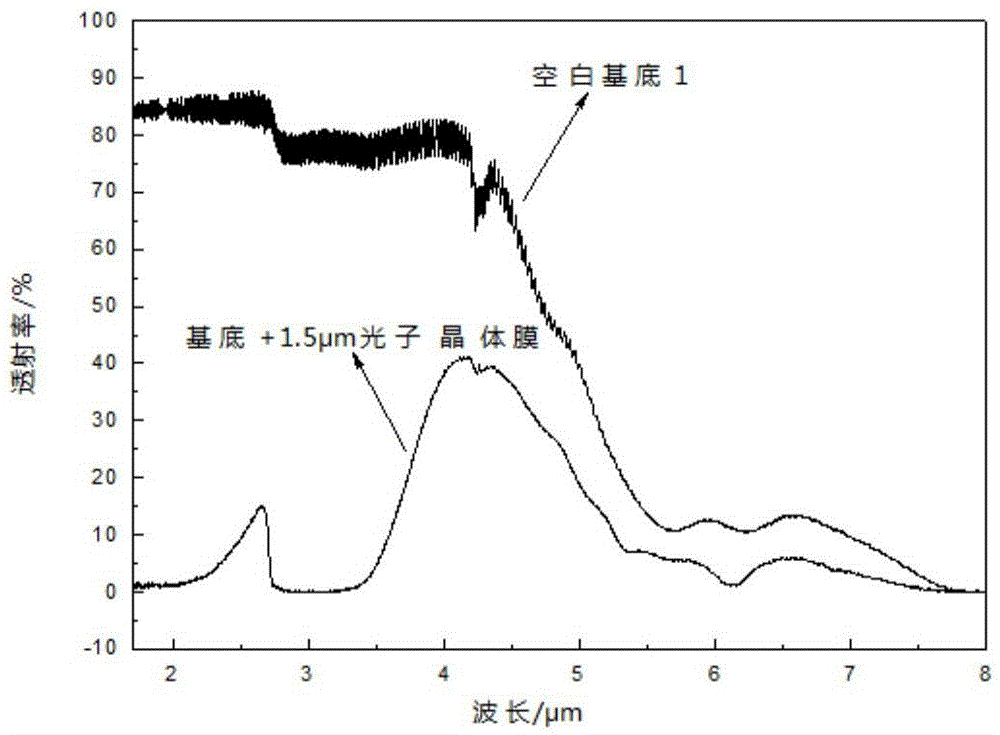

[0014] Example 2 1.5μm monodisperse SiO 2 Microspheres, dispersed in ethanol, controlled SiO 2 The concentration of microspheres was 1 mg / ml, and assembled by vertical deposition method at 60 °C and relative humidity of 50% for 6 h to obtain SiO 2 Photonic crystal film. SiO 2 Cover a glass slide above the photonic crystal film, drop a cellulose solution of appropriate concentration on the edge of the photonic crystal film, make the solution cover the entire photonic crystal film through the siphon diffusion of the solution, then remove the cover glass, and pour the The photonic crystal film of the cellulose solution was placed in a biological incubator at 60° C. for 1.5 hours to cure. The photonic crystal cellulose film was carefully removed from the glass slide to obtain a flexible photonic crystal material.

example 3

[0015] Example 3 3.0 μm monodisperse SiO 2 Microspheres, dispersed in dibromoethane-ethanol mixed solution, the volume ratio of dibromoethane to ethanol is 3:1, control SiO 2 The concentration of microspheres was 1 mg / ml, and assembled by vertical deposition method at 60 °C and relative humidity of 50% for 6 h to obtain SiO 2 Photonic crystal film. SiO will be obtained 2 The photonic crystal film was annealed in a tube furnace at 900 °C for 10 h to obtain SiO with enhanced mechanical strength 2 Photonic crystal materials. Finally, tape was carefully spread on the photonic crystal film, and after 10 minutes, the tape was carefully torn off to obtain a flexible photonic crystal material fixed by tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com