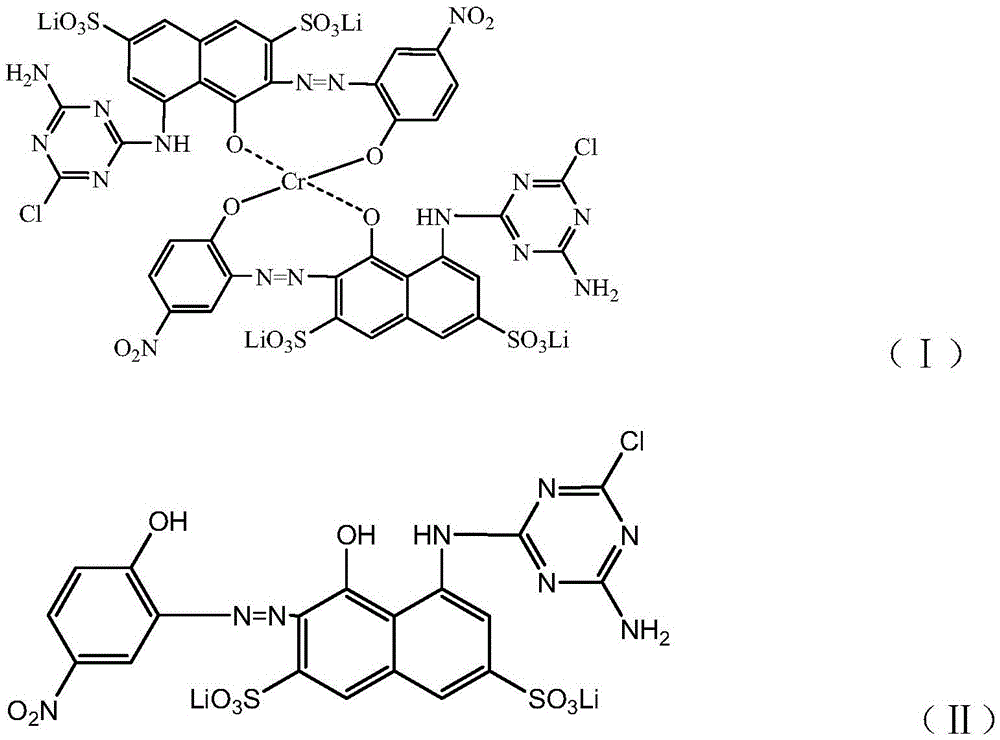

Gray reactive dye and preparation method thereof

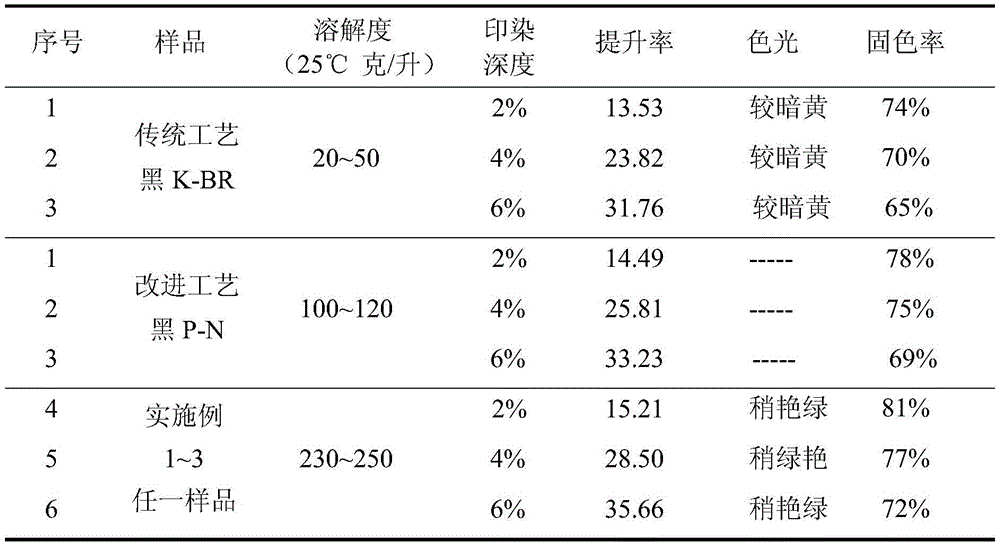

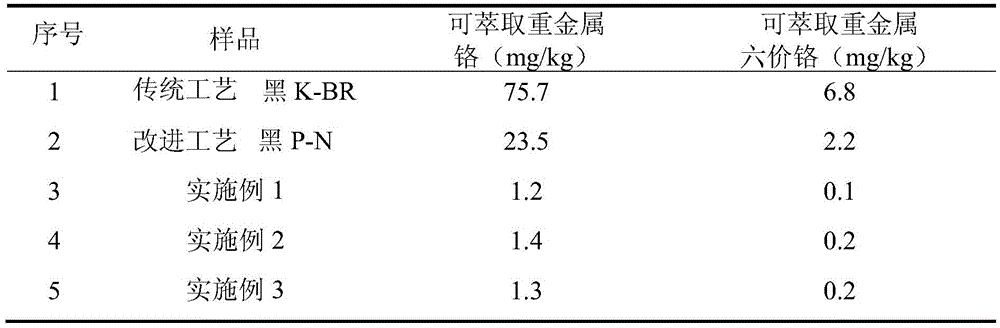

A gray and dye technology, applied in the field of reactive dye preparation, can solve the problems of insufficient Integ value, poor improvement performance, and insufficient solubility, and achieve the effects of good printing reproducibility, improved performance, and high color fixation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 1500L in the diazo kettle, heat up to 40°C, add 158 kg of 30% hydrochloric acid and 154 kg of 4-nitro-2-aminophenol, stir for 30 minutes to dissolve, then start to drop 230 kg of 30% sodium nitrite solution, Both the dropping temperature and the reaction temperature are controlled below 25°C, the reaction time is 60-90 minutes, and excess sodium nitrite is eliminated with sulfamic acid;

[0044]Add 1700L of bottom water to the coupling kettle, add 341 kg of H acid, and dissolve the H acid with 20% lithium hydroxide after stirring for 20 minutes. The pH value is controlled at 7.0-7.5. After a while, slowly add the diazonium salt prepared in step (1), the pH value is always greater than 6.5, and the temperature is 0-5°C for more than 10 hours;

[0045] After the end point of the coupling is reached, the temperature is raised to 60°C, and the pH is adjusted to 4.5-5.0 with 30% hydrochloric acid, and 10 kg of salicylic acid is added, and the temperature is continued to ...

Embodiment 2

[0049] Add 1500L in the diazo kettle, heat up to 40°C, add 158 kg of 30% hydrochloric acid and 154 kg of 4-nitro-2-aminophenol, stir for 30 minutes to dissolve, then start to drop 230 kg of 30% sodium nitrite solution, Both the dropping temperature and the reaction temperature are controlled below 25°C, the reaction time is 60-90 minutes, and excess sodium nitrite is eliminated with sulfamic acid;

[0050] Add 1700L of bottom water to the coupling kettle, add 341 kg of H acid, and dissolve the H acid with 20% lithium hydroxide after stirring for 20 minutes. The pH value is controlled at 7.0-7.5. After a while, slowly add the diazonium salt prepared in step (1), the pH value is always greater than 6.5, and the temperature is 0-5°C for more than 10 hours;

[0051] After the end point of the coupling is reached, heat up to 60°C, adjust the pH to 4.5-5.0 with 30% hydrochloric acid, add 12.5 kg of phthalic anhydride, continue to heat up to 100°C, add 125 kg of chromium trichloride ...

Embodiment 3

[0055] Add 1500L in the diazo kettle, heat up to 40°C, add 158 kg of 30% hydrochloric acid and 154 kg of 4-nitro-2-aminophenol, stir for 30 minutes to dissolve, then start to drop 230 kg of 30% sodium nitrite solution, Both the dropping temperature and the reaction temperature are controlled below 25°C, the reaction time is 60-90 minutes, and excess sodium nitrite is eliminated with sulfamic acid;

[0056] Add 1700L of bottom water to the coupling kettle, add 341 kg of H acid, and dissolve the H acid with 20% lithium hydroxide after stirring for 20 minutes. The pH value is controlled at 7.0-7.5. After a while, slowly add the diazonium salt prepared in step (1), the pH value is always greater than 6.5, and the temperature is 0-5°C for more than 10 hours;

[0057] After the end point of the coupling is reached, heat up to 60°C, adjust the pH to 4.5-5.0 with 30% hydrochloric acid, add 5 kg of salicylic acid and 5 kg of phthalic anhydride, continue to heat up to 100°C, and add 115...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com