Method for conducting fermentative production of citric acid by adding saccharifying enzyme stage by stage based on pH responses

A saccharification enzyme and citric acid technology, applied in the field of fermentation engineering, can solve problems such as the loss of saccharification enzyme activity, and achieve the effects of ensuring rapid growth, efficient utilization and shortening fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

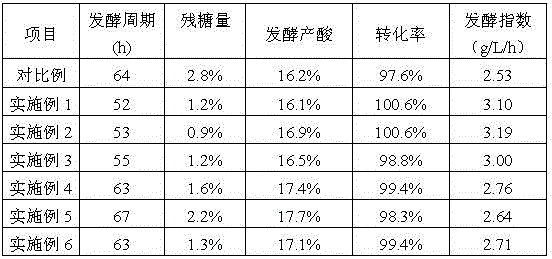

Embodiment 1

[0027] Mix cornflour and water evenly at a ratio of 1:1.5, adjust the pH to 5.8, then add high-temperature α-amylase, the addition amount is 50U / g cornflour; two spray liquefaction, the temperature of the first spray is 105 ° C, the second The injection temperature is 130°C, and the iodine test is qualified to obtain a liquefied mixed liquid, and part of the liquefied mixed liquid is filtered through a plate frame to obtain a liquefied clear liquid; the liquefied mixed liquid is mixed with water evenly, and a certain amount of ammonium sulfate is added to prepare a seed medium (total sugar 6%, total Niger 0.25%), inoculate the seed medium with the mature Aspergillus niger spore suspension, increase the stirring speed to 800rpm when culturing for 8 hours, and co-cultivate for 27 hours to obtain mature seed liquid; mix the liquefied mixed liquid, liquefied clear liquid and water to prepare fermentation culture base (total sugar 16%, total nitrogen 0.05%); inoculate the mature see...

Embodiment 2

[0029] Mix cornflour and water evenly in a ratio of 1:4, adjust the pH to 6.0, then add high-temperature α-amylase, the addition amount is 15U / g cornflour; two sprays are liquefied, the temperature of the first spray is 95°C, and the second spray is liquefied. The injection temperature is 120°C, and the iodine test is qualified to obtain a liquefied mixed solution, and part of the liquefied mixed solution is filtered through a plate frame to obtain a liquefied clear solution; the liquefied mixed solution is mixed with water evenly, and a certain amount of ammonium sulfate is added to prepare a seed medium (total sugar 10%, total Niger 0.30%), the mature Aspergillus niger spore suspension was inoculated into the seed medium, cultivated for 26 hours, and the mature seed liquid was obtained; the liquefied mixed liquid, the liquefied clear liquid and water were mixed to prepare a fermentation medium (total sugar 16.8%, total nitrogen 0.08% ); Inoculate the mature seed liquid into t...

Embodiment 3

[0031] Mix cassava flour and water evenly at a ratio of 1:2.5, adjust the pH to 5.9, then add high-temperature α-amylase, the addition amount is 25U / g cassava flour; two sprays are liquefied, the temperature of the first spray is 100°C, and the second spray is liquefied. The injection temperature is 125°C, and the iodine test is qualified to obtain a liquefied mixed liquid, and part of the liquefied mixed liquid is filtered through a plate frame to obtain a liquefied clear liquid; the liquefied mixed liquid is mixed with water evenly, and a certain amount of ammonium sulfate is added to prepare a seed medium (total sugar 12%, total Niger 0.40%), the mature Aspergillus niger spore suspension was inoculated into the seed medium, cultivated for 30 hours, and the mature seed liquid was obtained; the liquefied mixed liquid, the liquefied clear liquid and water were mixed to prepare a fermentation medium (total sugar 16.7%, total nitrogen 0.12% ); inoculate the mature seed liquid int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com