Method for preparing moisture-proof anti-caking nutritional supplement

A technology of nutritional fortifiers and nutritional additives, which is applied in the fields of food ingredients as anti-caking agents, food ingredients as pH value modifiers, food science, etc. It can prevent problems such as smoothness and hanging water droplets, so as to prevent clumping, reduce moisture absorption and increase stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

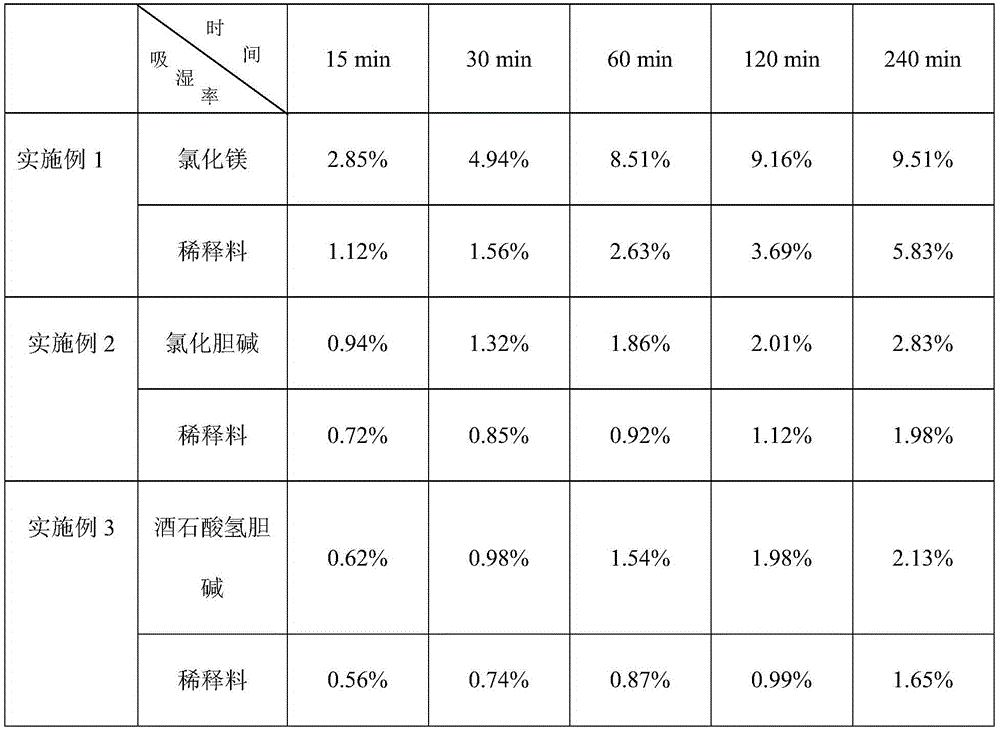

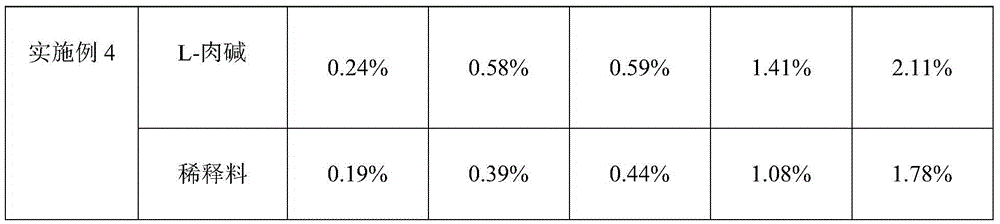

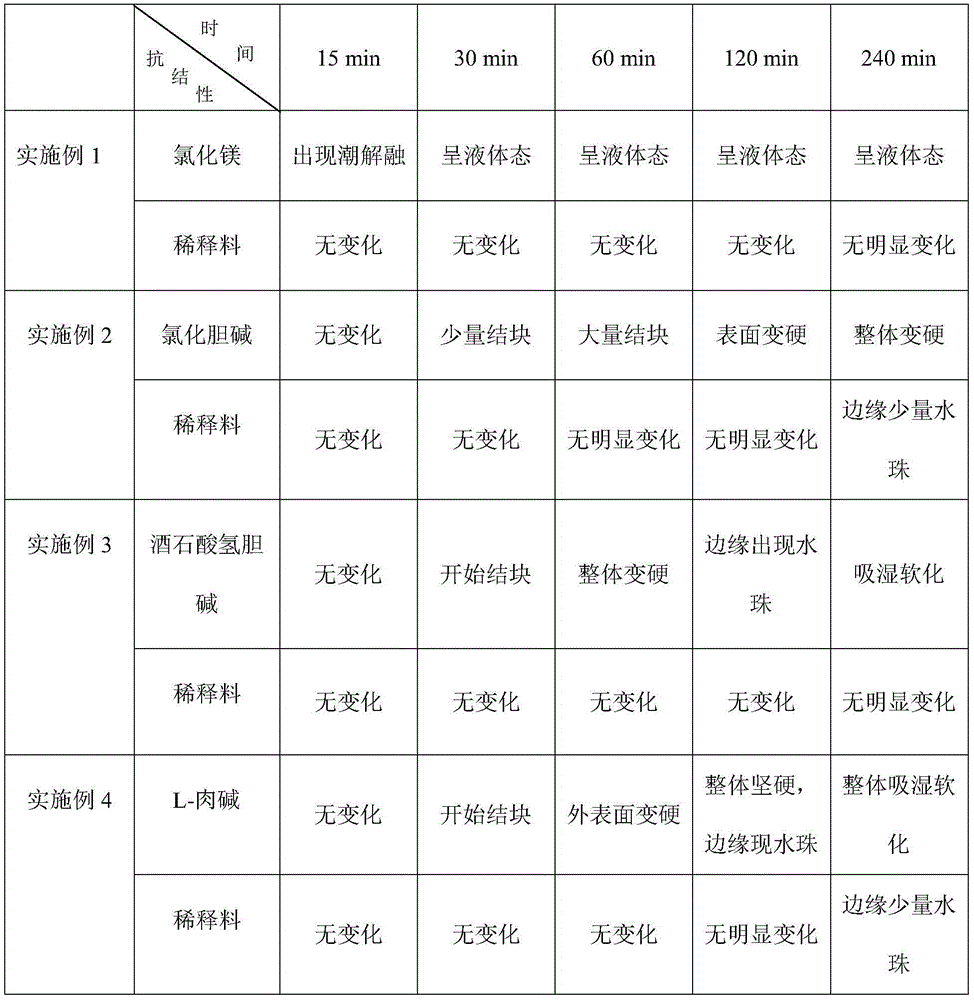

Embodiment 1

[0030] The invention discloses a preparation method of a moisture-proof and anti-caking nutrition enhancer, which comprises the following steps:

[0031] Process 600L of process water in a 1000L emulsification tank, emulsify and mix 30.0kg of food-grade magnesium chloride (hexahydrate) and 270.0kg of microcrystalline cellulose at room temperature for 20 minutes, and obtain a uniform semi-finished trace element compound dilution material through spray drying. Spray The air inlet temperature of drying is 180 DEG C, and the air outlet temperature is 95 DEG C, and then mixed with 3.0 kg of tricalcium phosphate and 25.0 kg of sodium sodium malate to obtain 311.8 kg of magnesium chloride dilution.

Embodiment 2

[0033] The invention discloses a preparation method of a moisture-proof and anti-caking nutrition enhancer, which comprises the following steps:

[0034] Process 400L of process water in a 1000L emulsification tank, emulsify and mix 5.5kg of food-grade choline chloride and 94.5kg of inulin at room temperature for 20 minutes, and spray dry to obtain a uniform semi-finished trace element compound dilution material. The spray-dried air inlet Temperature 180 ℃, air outlet temperature 95 ℃, then mix with 2.8kg tricalcium phosphate and 7.3kg hydroxypropyl starch to obtain choline dilution material 100.9kg.

Embodiment 3

[0036] The invention discloses a preparation method of a moisture-proof and anti-caking nutrition enhancer, which comprises the following steps:

[0037] Process 600L of process water in a 1000L emulsification tank, emulsify and mix 50.0kg of food-grade choline bitartrate and 250.0kg of inulin at room temperature for 20 minutes, and spray dry to obtain a uniform semi-finished trace element compound dilution material. The spray-dried air inlet The temperature is 200°C, and the air outlet temperature is 100°C, and then mixed with 0.8kg of silicon dioxide and 10.3kg of hydroxypropyl starch to obtain 298.9kg of choline dilution material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com