A functional composite metal oxide material and its preparation method and application

A composite metal and oxide technology, applied in the field of cobalt, nickel, manganese composite metal oxide materials, can solve the problem of high cost, achieve the effect of improving the utilization rate, the method is simple and easy, and the mass production is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

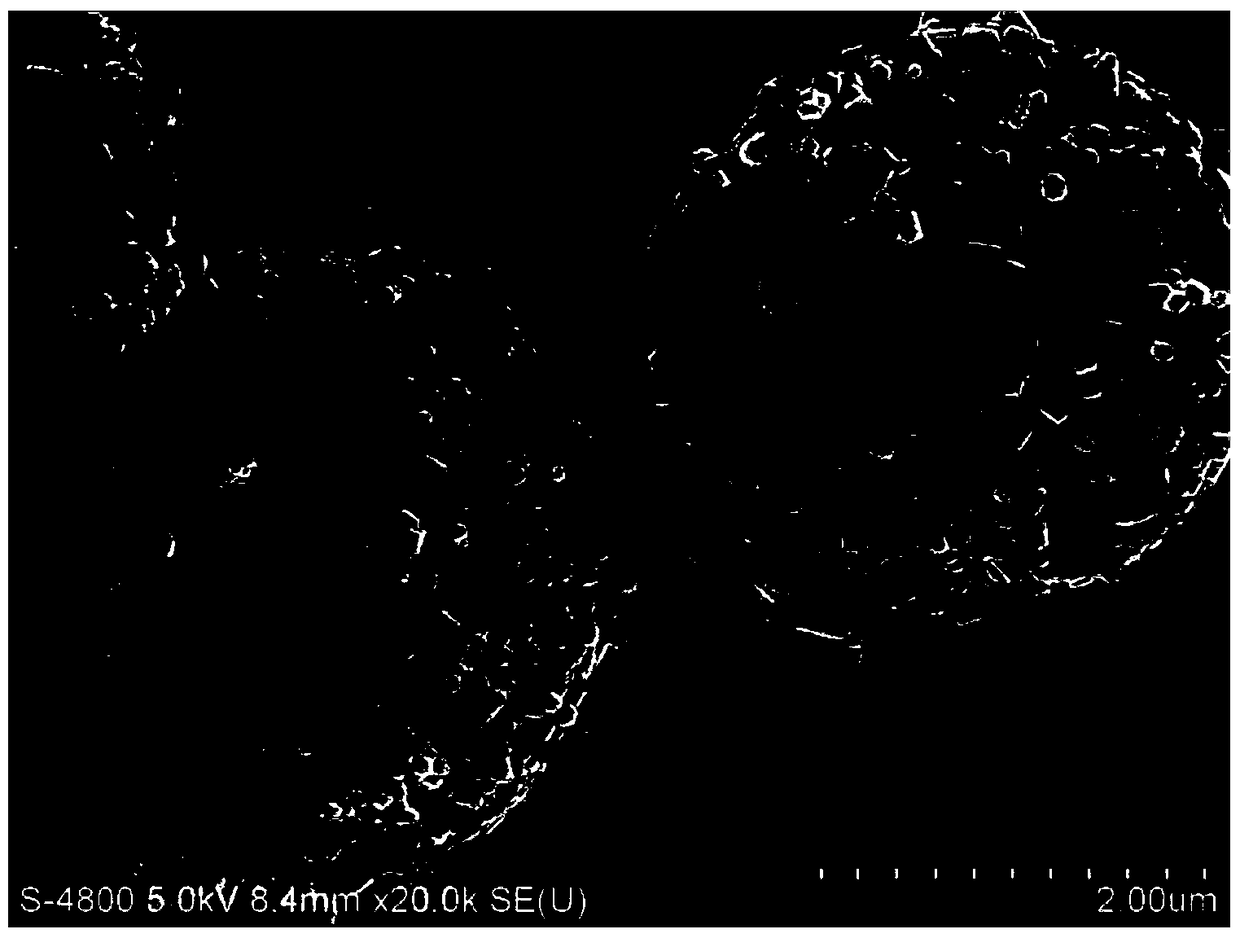

[0032] Nickel, cobalt, manganese composite metal oxide material MnCoNiO 4 The synthesis of comprises three steps of co-precipitation, grinding and high temperature treatment, and the specific preparation method is as follows:

[0033] (1) Add 10mmol NiSO to a 1000mL beaker 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O, then add 500 mL of deionized water until completely dissolved. An appropriate amount of ammonia water was added to adjust the pH of the solution to 10. Prepare 200 mL of a sodium carbonate solution with a concentration of 27.5 μg / mL, and then add it dropwise to the metal salt solution under heating and stirring at 70°C until the precipitation is complete. Wash the precipitate 3 times with deionized water, filter and dry the precipitate in a drying oven at 70°C for 10 hours;

[0034] (2) Use an agate mortar to fully grind the precipitate obtained in step (1) for 1 hour;

[0035] (3) Put the fully ground precipitate obtained in step (2) into a crucible, then ...

Embodiment 2

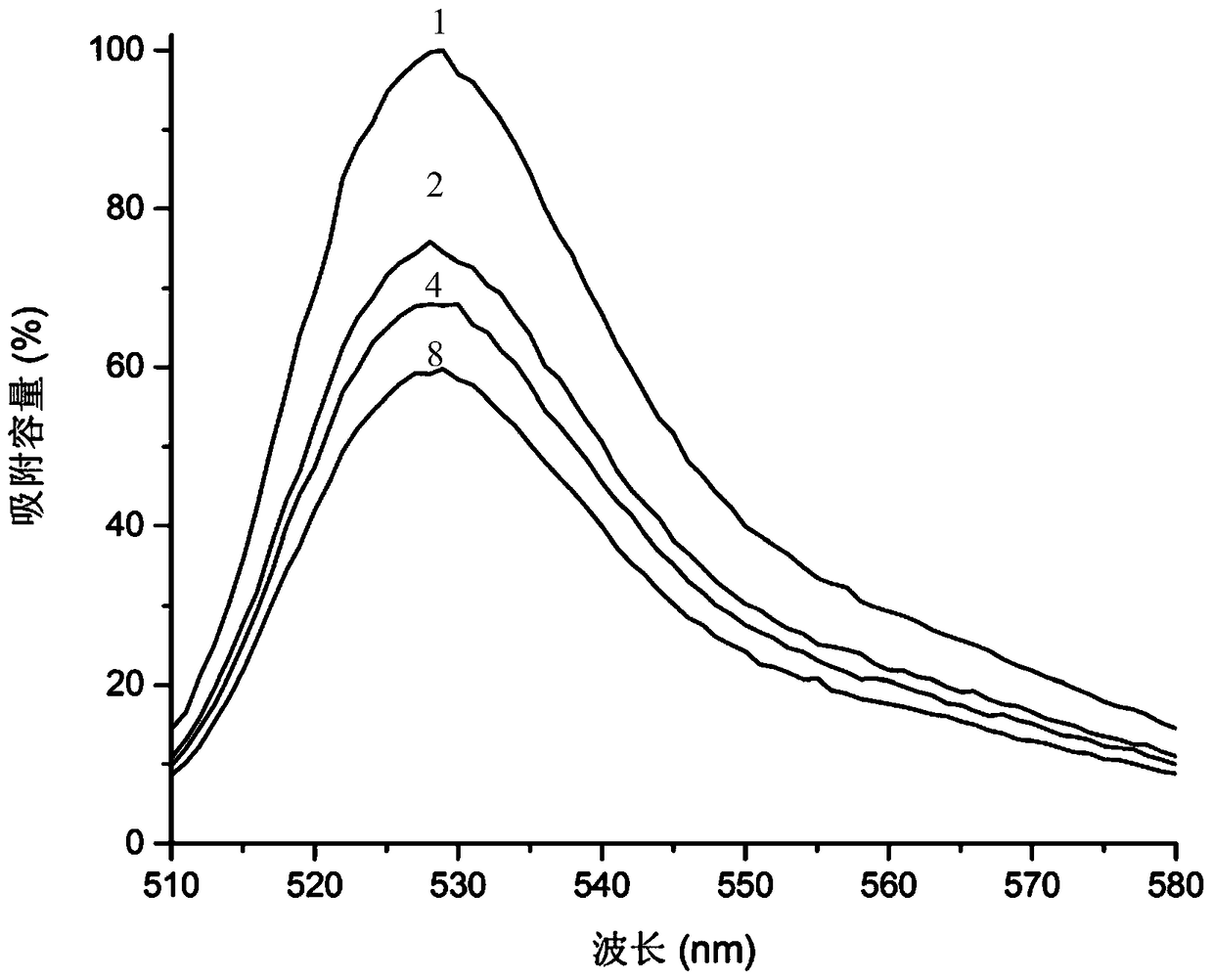

[0038] Nickel, cobalt, manganese composite metal oxide material MnCoNiO 4 The specific steps for isolating the hexahistidine-labeled yellow fluorescent protein in the enrichment solution are as follows:

[0039] 200 μg MnCoNiO 4 The microspheres were mixed with 500 μL of 20 μg / mL hexahistidine-labeled yellow fluorescent protein solution at room temperature for 5 minutes, centrifuged at 10,000 rpm for 2 minutes, and the supernatant was discarded. Then, 200 μL of phosphate buffer solution (pH=7.40) was added to the centrifuge tube, mixed for 1 min, and the supernatant was discarded after centrifugation. This washing process was repeated 2 times. Finally, 20 μL of 1 mol / L imidazole solution was added to the bottom of the centrifuge tube, rotated and mixed for 5 minutes, centrifuged at 10,000 rpm for 2 minutes, and the supernatant was retained. The supernatant is the composite metal oxide material MnCoNiO 4 The resulting hexahistidine-tagged yellow fluorescent protein solution...

Embodiment 3

[0042] Nickel, cobalt, manganese composite metal oxide material MnCoNiO 4 Separation and purification of the hexahistidine-labeled green fluorescent protein in the cell lysate, the specific steps are as follows:

[0043] The Escherichia coli expressing the hexahistidine-tagged green fluorescent protein was ultrasonically lysed, then centrifuged at a centrifugation rate of 12000 rpm for 20 min, and the supernatant was retained. Then 200 μg MnCoNiO was added to 200 μL supernatant 4 The microspheres were rotated and mixed for 5 minutes at room temperature, centrifuged at 10000 rpm for 2 minutes, and the supernatant was discarded. Then add 200 μL of 10 mmol / L imidazole solution to the centrifuge tube, mix for 1 min, and discard the supernatant after centrifugation. This washing process was repeated 3 times. Finally, 20 μL of 1 mol / L imidazole solution was added to the bottom of the centrifuge tube, rotated and mixed for 5 minutes, centrifuged at 10,000 rpm for 2 minutes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com