Graphite phase-like carbon nitride/tetracarboxylphenylporphyrin nano-composite material and preparation method therefor

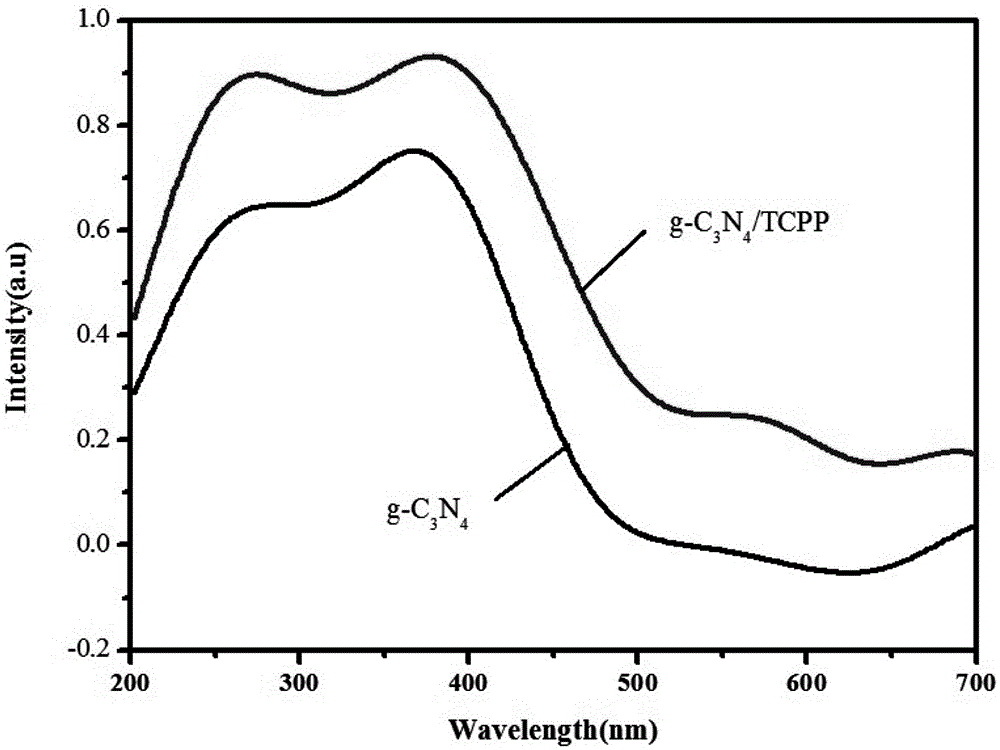

A nano-composite material, phenyl porphyrin technology, applied in the field of electroanalytical chemistry, can solve the problems of low photogenerated electron-hole composite quantum efficiency, inability to effectively utilize sunlight, restricting large-scale popularization and application, etc., so as to improve light energy. utilization, improving photocatalytic performance, and the effect of good photoelectrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

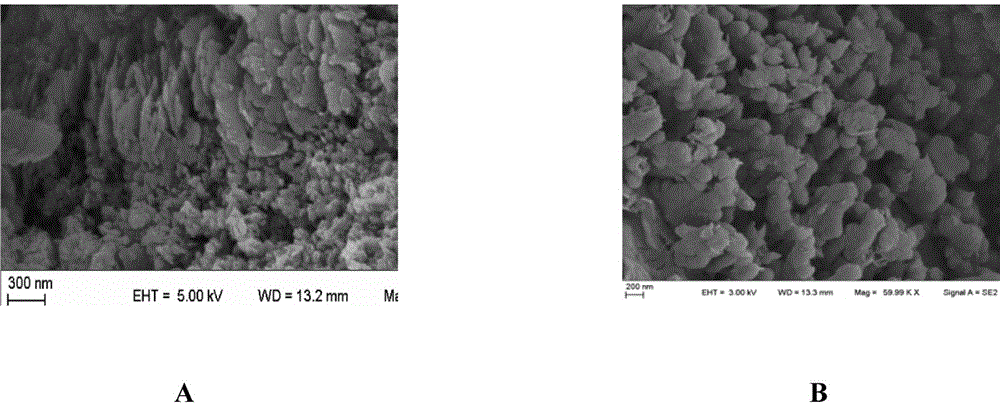

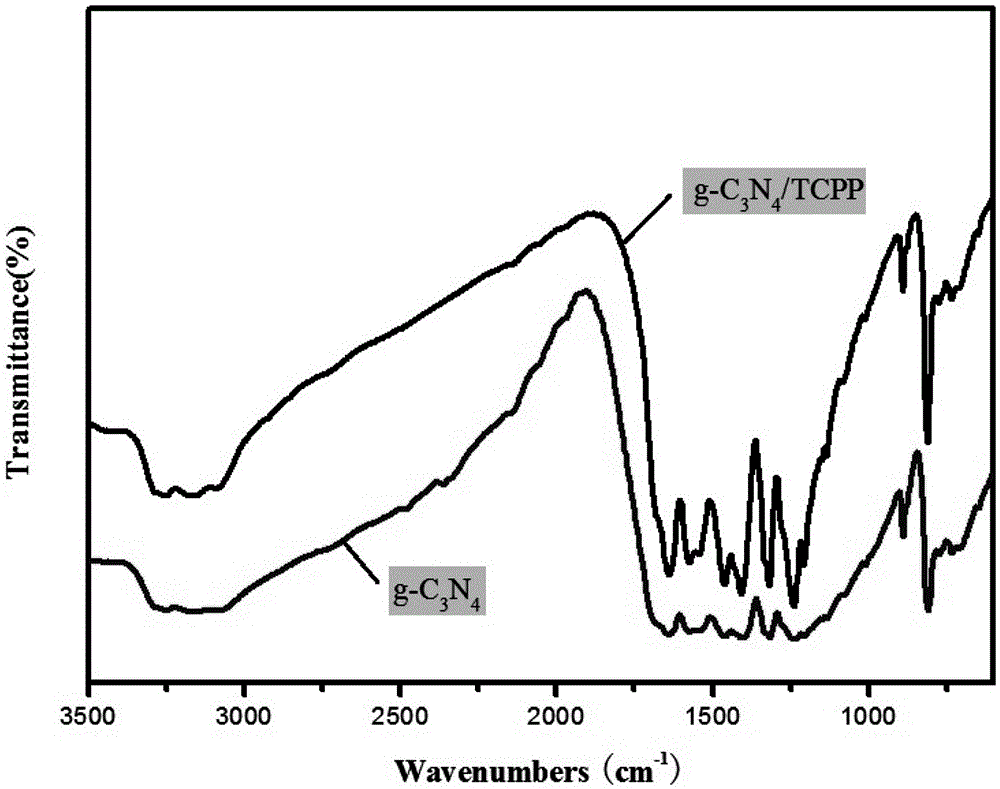

[0028] The preparation method of a graphite-like carbon nitride / tetracarboxyphenylporphyrin nanocomposite material of the present invention is:

[0029] (1) Weigh 5g of melamine solid sample into a 25ml porcelain crucible, cover the crucible and put it into the muffle furnace, heat up to 550°C at a rate of 4°C / min, and keep it at 550°C for 4 hours , Then lower to room temperature, take out the crucible, and obtain graphite-like carbon nitride, which is a light yellow solid; the crucible is covered without any protective gas during the whole process; it is ground into powder for later use;

[0030] (2) Weigh 0.2 g of the graphite-like carbon nitride powder prepared in step (1), add 10 ball milling beads and stir for 2.5 hours at 400 rpm;

[0031] (3) Take out the carbon nitride powder and clean the ball milling tank, put 10mg tetracarboxyphenylporphyrin, 200mg carbon nitride powder and 10 ball milling beads into the ball milling tank together, and stir at 300rpm for 40min. The obtain...

Embodiment 2

[0036] The preparation method of a graphite-like carbon nitride / tetracarboxyphenylporphyrin nanocomposite material of the present invention is:

[0037] (1) Weigh 8g solid sample of melamine into a 25ml porcelain crucible, cover the crucible and put it in the muffle furnace, heat up to 550°C at a rate of 4°C / min, and keep it at 550°C for 4.5 hours , Then lower to room temperature, take out the crucible, and obtain graphite-like carbon nitride, which is a light yellow solid; the crucible is covered without any protective gas during the whole process; it is ground into powder for later use;

[0038] (2) Weigh 0.2g of the graphite-like carbon nitride powder prepared in step (1), add 12 ball milling beads and stir at 350rpm for 2h;

[0039] (3) Take out the carbon nitride powder and clean the ball mill tank, put 10 mg of tetracarboxyphenyl porphyrin, 200 mg of carbon nitride powder and 12 ball milling beads into the ball mill tank, and stir for 50 min at 350 rpm. The obtained solid is t...

Embodiment 3

[0041] The preparation method of a graphite-like carbon nitride / tetracarboxyphenylporphyrin nanocomposite material of the present invention is:

[0042] (1) Weigh 10g solid sample of melamine into a 25ml porcelain crucible, cover the crucible and put it into the muffle furnace, heat up to 550°C at a rate of 5°C / min, and keep it at 550°C for 4 hours , Then lower to room temperature, take out the crucible, and obtain graphite-like carbon nitride, which is a light yellow solid; the crucible is covered without any protective gas during the whole process; it is ground into powder for later use;

[0043] (2) Weigh 0.2g of the graphite-like carbon nitride powder prepared in step (1), add 15 ball milling beads and stir at 300rpm for 3h;

[0044] (3) Take out the carbon nitride powder and clean the ball mill tank, put 10mg tetracarboxyphenylporphyrin, 200mg carbon nitride powder and 15 ball milling beads into the ball mill tank together, and stir for 30min at 400rpm. The obtained solid is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com