Composite high-efficiency flocculating agent and sewage treatment method and matched sewage treatment device

A sewage treatment method and composite flocculant technology, which are applied in the fields of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. , it is difficult to meet the emission standards, etc., to achieve the effect of stable and reliable operation, simple and efficient demulsification, and saving equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The purpose of this embodiment is to provide a high-efficiency composite flocculant suitable for treating fluorescent wastewater and a wastewater treatment method.

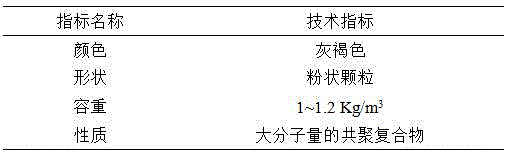

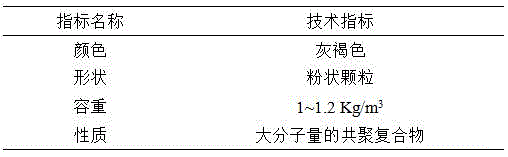

[0033] This embodiment specifically provides a high-efficiency composite flocculant for sewage treatment, comprising the following mass fractions: organic polymer demulsifier, 5-25%; inorganic flocculant, 15-55%; organic quick-acting assistant Coagulant, 0.5~10%; Inorganic micropowder oil absorbent, 25~60%.

[0034] Specifically, the high-efficiency composite flocculant includes the following mass fractions: organic polymer demulsifier, 10-20%; inorganic flocculant, 30-42%; organic quick-acting coagulant, 1-5%; inorganic micro-powder oil-absorbing agent agent, 40~50%.

[0035] Specifically, the high-efficiency composite flocculant includes the following mass fractions: organic polymer demulsifier, 15%; inorganic flocculant, 37%; organic quick-acting coagulant, 3%; inorganic micro-powder oil-absorbing agent...

Embodiment 2

[0058] The purpose of this embodiment is to provide a high-efficiency composite flocculant suitable for treating wastewater containing fluorescence. The specific mass ratios of various substances are: organic polymer demulsifier, 13%; inorganic flocculant, 39%; organic quick-acting coagulant aid, 2.5%; inorganic micropowder oil-absorbing agent, 45.5%. The high-efficiency composite flocculant is in dry powder form.

Embodiment 3

[0060] The purpose of this embodiment is to provide a high-efficiency composite flocculant suitable for treating wastewater containing fluorescence. The specific mass ratios of various substances are: organic polymer demulsifier, 17%; inorganic flocculant, 35%; organic quick-acting coagulant aid, 7%; inorganic micro-powder oil-absorbing agent, 41%. The high-efficiency composite flocculant is in dry powder form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com