Culture wastewater efficient degrading and denitrifying treatment system and treatment method thereof

A technology for aquaculture wastewater and nitrogen treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Slow reproduction, low processing costs, and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

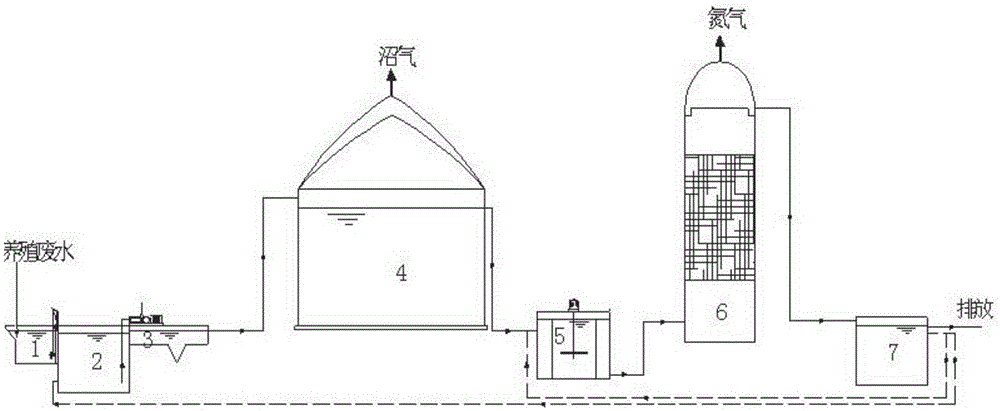

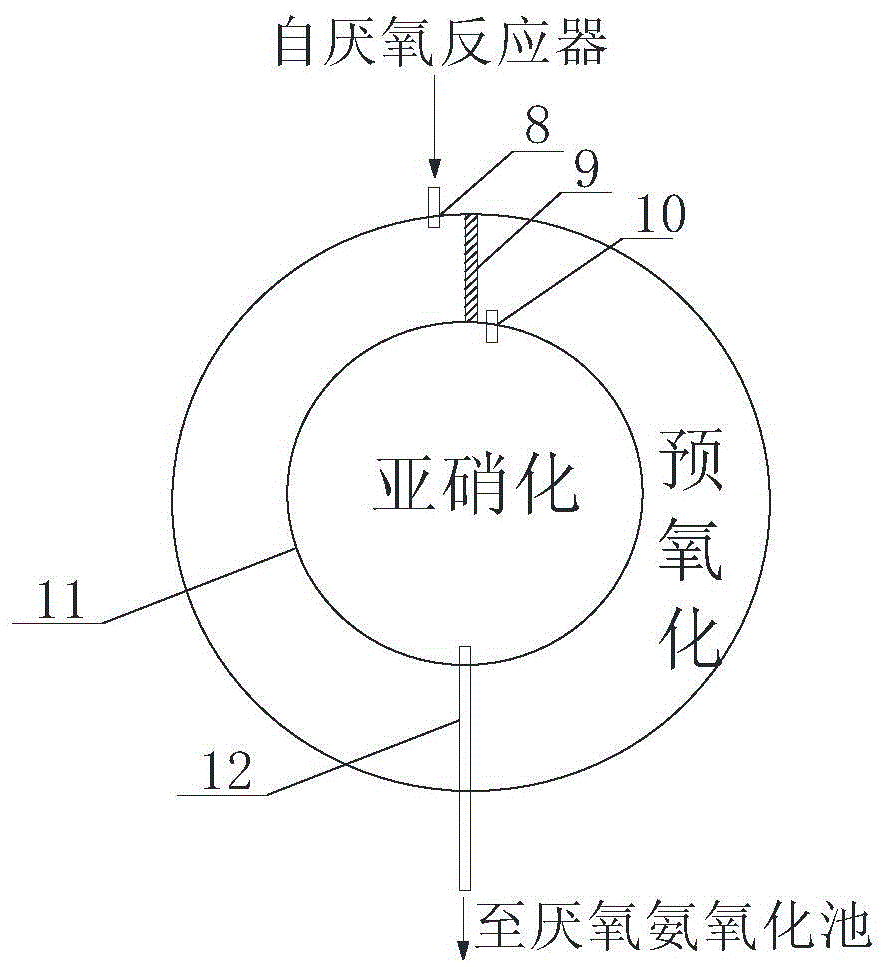

[0048] A high-efficiency degradation and denitrification treatment system for aquaculture wastewater, with a structure such as figure 1 , figure 2 As shown, it includes the regulating tank 1, the grit tank 2, the feed tank 3, the anaerobic reactor 4, the pre-oxidation-nitrosation integrated tank 5, the anaerobic ammonia oxidation reactor 6 and the effluent return tank 7, which are connected in sequence, The anaerobic reactor 4 is an anaerobic internal circulation reactor. The pre-oxidation-nitrosation integrated tank 5 includes two cylindrical tank bodies inside and outside, and an annular outer ring tank cavity is formed between the outer tank body and the inner tank body. , The inner tank body encloses an inner ring tank cavity, the inner ring tank cavity is connected with the outer ring tank cavity, the pre-oxidation-nitrosation integrated tank outer ring tank cavity is provided with a diversion wall 9 inside the inner ring tank cavity A paddle agitator is provided, the out...

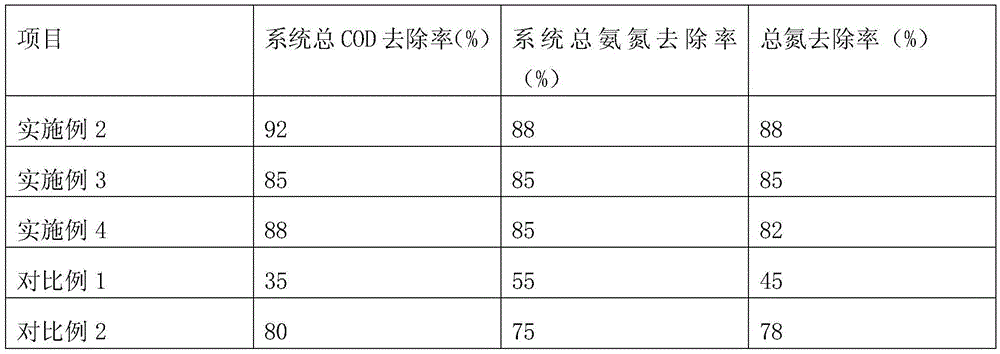

Embodiment 2

[0052] Treating 30t / d of wastewater from dairy farms, the wastewater quality is COD3000~4000mg / L, NH 4 -N550~650mg / L, pH7.8~8.0,

[0053] The treatment method of using the treatment system of Example 1 to carry out efficient degradation and denitrification of aquaculture wastewater,

[0054] Adjusting pool volume 30m 3 , The size is length×width×height=5.0×3.0×2.0m; the volume of the feeding tank is 30m 3 , The size is length×width×height=4.0×3.0×2.5m; the grit chamber adopts advection grit chamber with a volume of 7.2m 3 , Size is length×width×height=6.0×1.0×1.2m; anaerobic reactor adopts IC reactor, volume 100m 3 , Size is diameter×height=φ3.6×9.8m; pre-oxidation-denitrification integrated tank volume 6m 3 , The size is diameter×height=φ1.5×1.0m, the inner ring diameter is 1.06m, the inner ring tank is equipped with a paddle mixer, the mixer power is 0.75kW; the anaerobic ammonia oxidation reactor adopts an upflow anaerobic filter with a volume of 30m 3 , The size is diameter×heigh...

Embodiment 3

[0064] Treating 100t / d of dry cleaning pig farm wastewater, the quality of the breeding wastewater is COD2000~3000mg / L, NH 4 -N600~700mg / L, pH7.2~7.8

[0065] The treatment method of using the treatment system of Example 1 to carry out efficient degradation and denitrification of aquaculture wastewater,

[0066] Adjusting pool volume 100m 3 , The size is length×width×height=5.0×5.0×4.0m; the volume of the feeding tank is 60m 3 , The size is length×width×height=5.0×4.0×3.0m; the grit chamber adopts advection grit chamber with a volume of 24m 3 , The size is length×width×height=10.0×2.0×1.2m; the anaerobic reactor adopts IC reactor with a volume of 300m 3 , The size is diameter×height=φ5.2×14.0m;

[0067] Pre-oxidation-denitrification integrated tank volume 21m 3 , The size is diameter×height=φ4.2×1.5m, the inner ring diameter is 3.0m, the inner ring tank is equipped with a paddle mixer, the mixer power is 1.5kW; the anaerobic ammonia oxidation reactor adopts an upflow anaerobic filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com