A sewage treatment device and process for cyclic sequence batch operation

A sewage treatment and sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, sedimentation treatment, etc., to achieve good effect, low operating cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

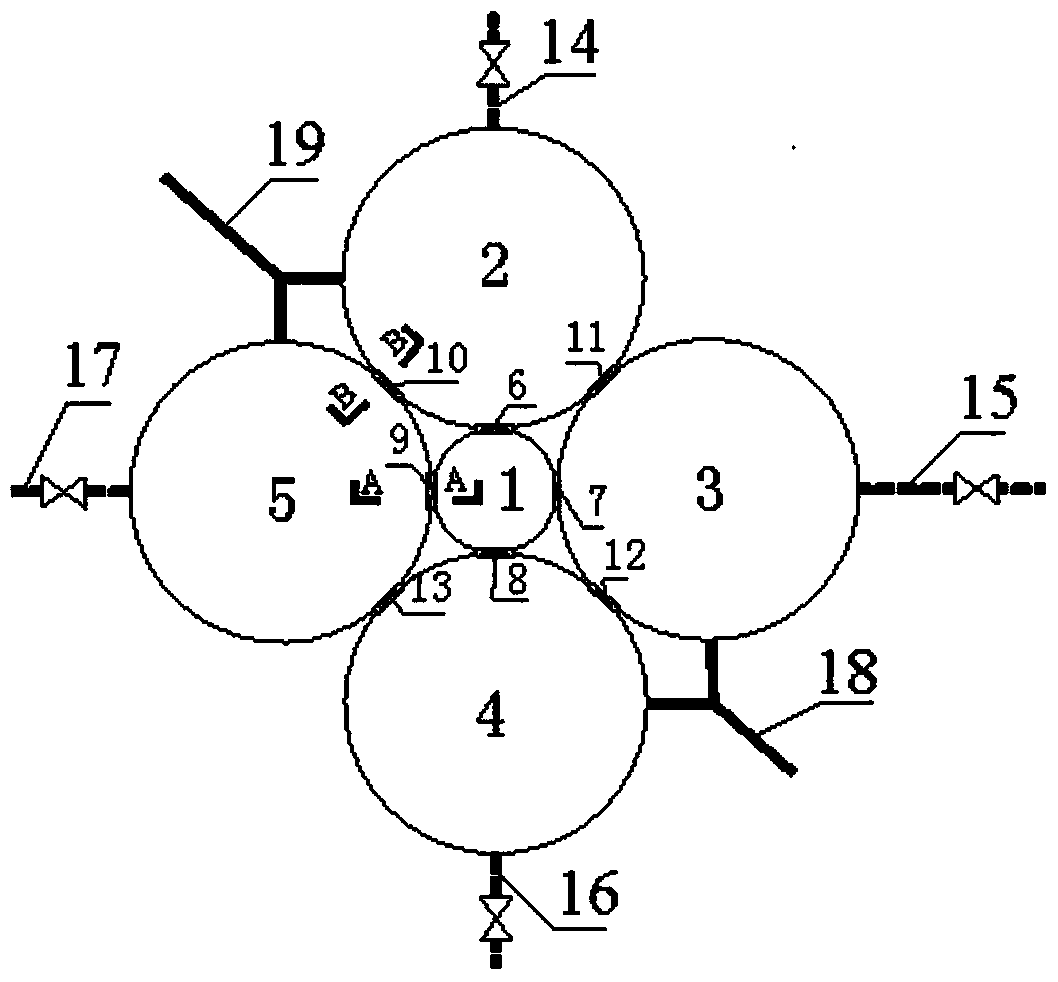

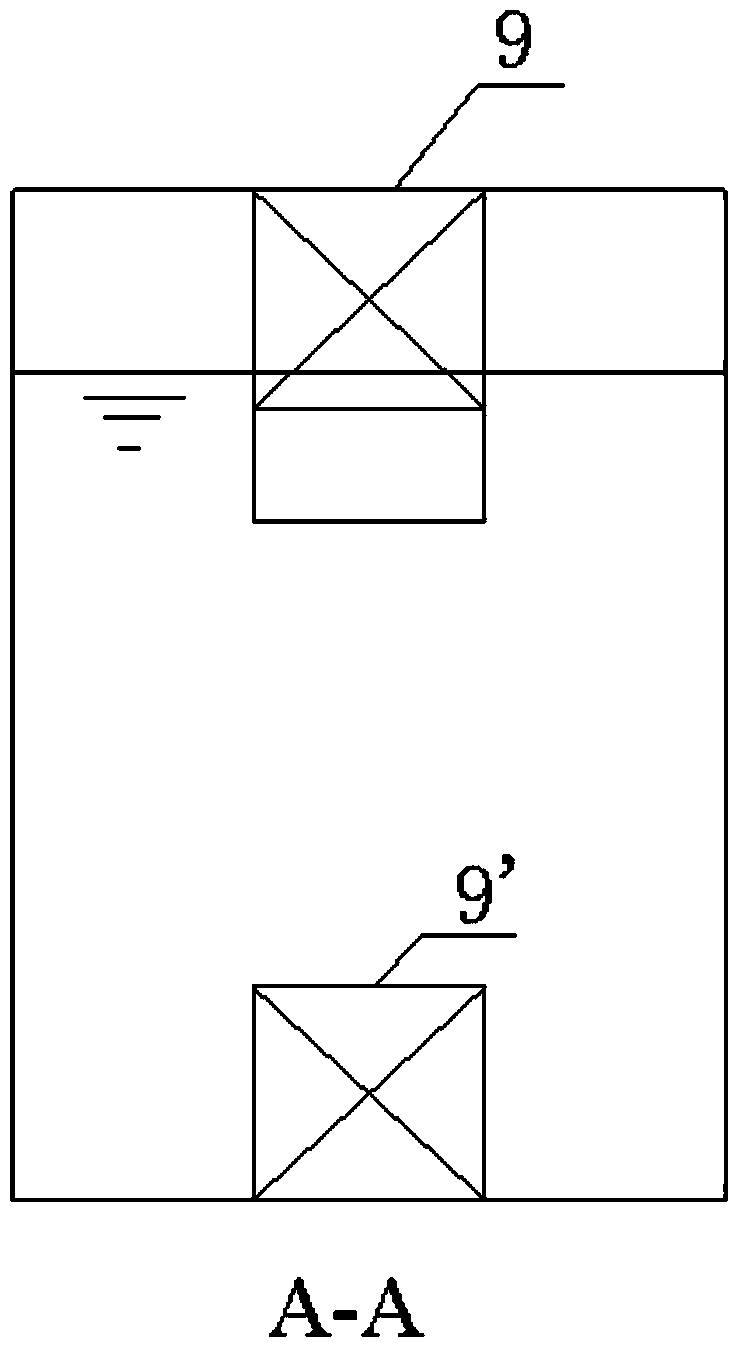

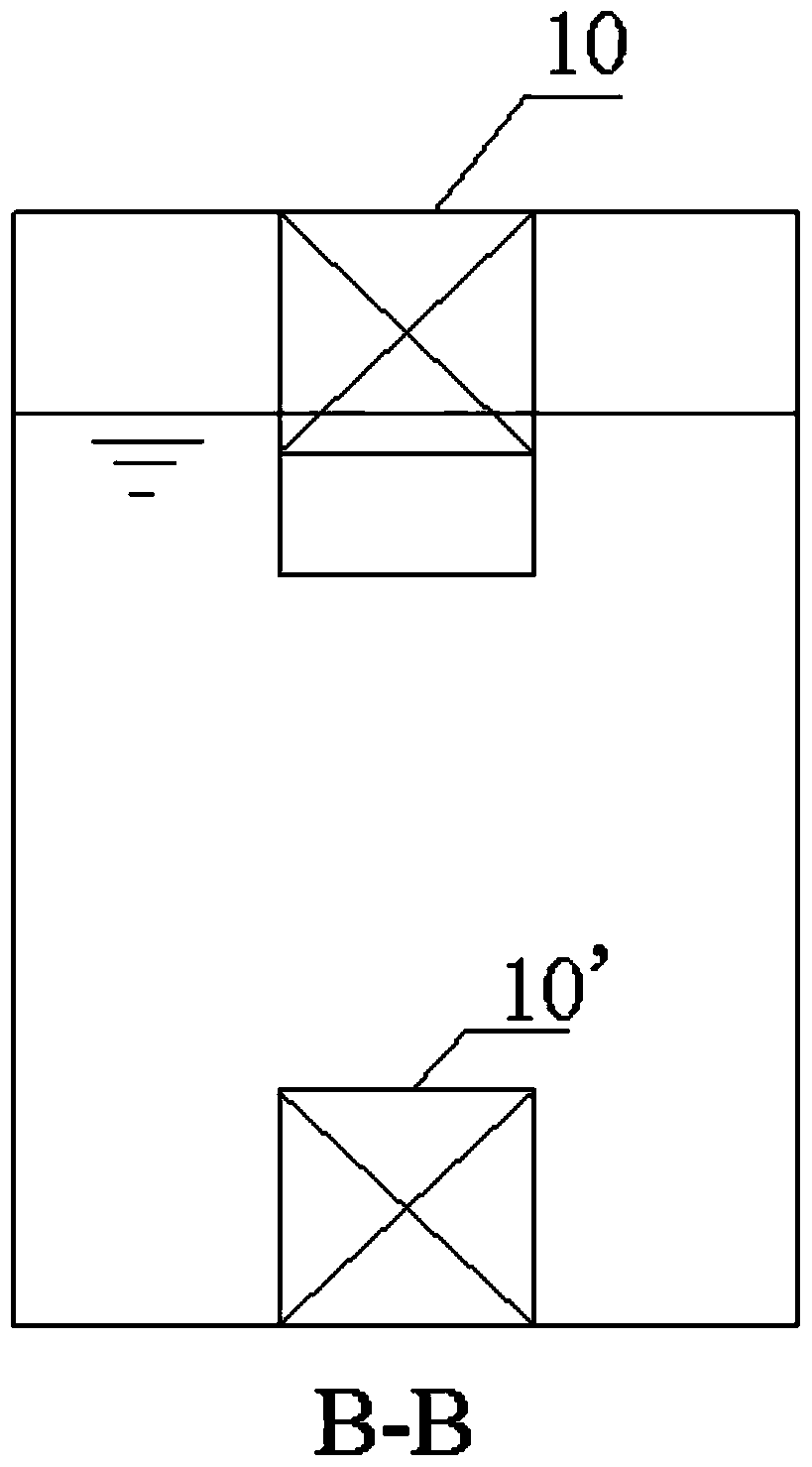

[0038] The single pool operates with the traditional SBR process, and its flow chart is as follows Figure 4 shown. Sewage enters the first SBR pool 2, the second SBR pool 3, the third SBR pool 4 and the fourth SBR pool 5 from the central pool 1 respectively. A single SBR pool has five processes of water intake, reaction, sedimentation, drainage, and idleness. Batch operation. Multiple SBR pools run in parallel, and each SBR pool is independent of each other without interfering with each other.

Embodiment 2

[0040] The combination of four SBR pools and two pools operates in the form of CASS process, and its flow chart is as follows Figure 5 shown. The first SBR pool 2 and the third SBR pool 4 are used as sedimentation tanks in the later stage of the reaction, and the second SBR pool 3 and the fourth SBR pool 5 are used as reaction pools. The sewage first enters the central pool 1. After the sedimentation period, the sedimented sludge in the first SBR pool 2 and the third SBR pool 4 also flows back to the central pool 1. At this time, the central pool 1 acts as a biological selector, and then the sewage enters the second SBR. The pool 3 and the fourth SBR pool 5, the second SBR pool 3 and the fourth SBR pool 5 operate in a part-aerobic manner to carry out denitrification and denitrification activities. Then the mixed solution in the second SBR pool 3 enters the third SBR pool 4 through the gate, and the mixed solution in the fourth SBR pool 5 enters the first SBR pool 2 through t...

Embodiment 3

[0042] The four-pool combination operates in the form of A2 / O process, and its flow chart is as follows Figure 7 shown. The central pool 1 is an inlet pool, and the central pool 1 also serves as a regulating pool. The sewage treated in the central pool 1 first enters the first SBR pool 2, and the first SBR pool 2 operates in an anaerobic manner. The return sludge in 2 is anaerobic phosphorus released in the first SBR tank 2, and the organic matter in the influent is anaerobic ammonification at the same time. The water flow in the first SBR pool 2 continues to enter the second SBR pool 3 through the gate, and the second SBR pool 3 operates in a part-aerobic mode, while returning from the third SBR pool 4 to the central pool 1 through the gate, and the central pool 1 The raw sewage in the mixed solution enters the second SBR tank 3 through the gate, and denitrification and denitrification are carried out in the second SBR tank 3, and phosphorus release continues in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com