Baking-free ceramic water permeable brick and preparation method thereof

A manufacturing method and technology of permeable bricks, which are applied in the directions of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of inapplicability to re-production, difficult recycling and reuse, etc., and achieve good water permeability and good water permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a non-fired ceramic permeable brick with unique water permeability and water permeability made of waste ceramics, including: ceramic granules with a polymer coating and an adhesive, and the polymer coating The ceramic granules are mixed and bonded by the adhesive and solidified; wherein, the particle diameter of the ceramic granules is 0.01-20mm, and the polymer coating is epoxy resin adhesive, acrylic resin adhesive and polyurethane adhesive. One or more; the adhesive is one or more of epoxy resin adhesives, acrylic resin adhesives and polyurethane adhesives. Use ceramic granules with a particle diameter of 0.01-20mm and polymers to make particles with a polymer coating, and then use an adhesive to bond the ceramic granules with a polymer coating to form a building material with good water permeability. , the building material can be applied to the production of building materials, realizing the recovery and utilization of ceramic granules. Th...

Embodiment 2

[0037]This embodiment provides a method for preparing a water-permeable functional brick, which includes mixing, molding and curing the ceramic granules according to the present invention and a polymer.

[0038] Specific steps include:

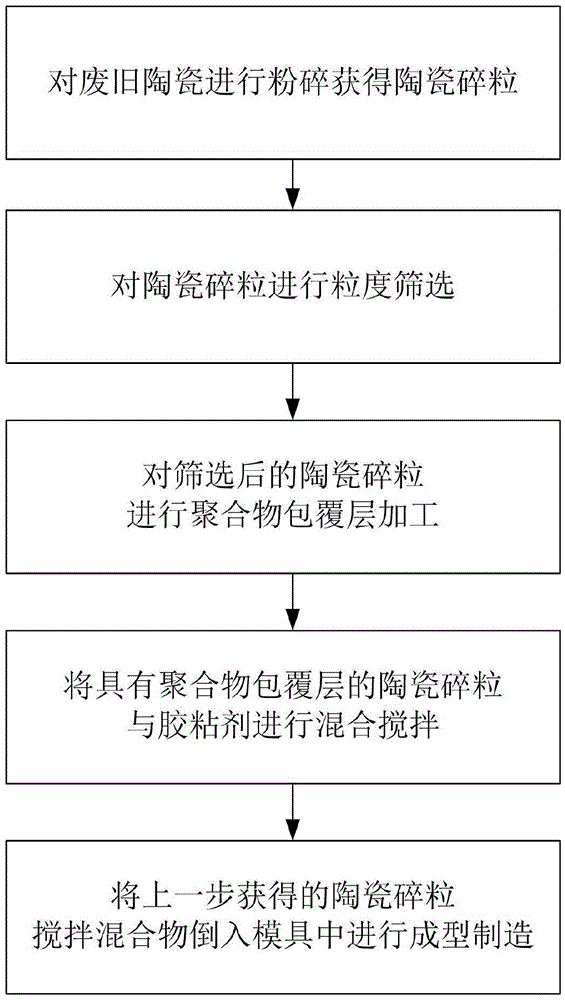

[0039] Step S1: crushing waste ceramics to obtain ceramic granules;

[0040] Step S2: performing particle size screening on the ceramic granules, and selecting ceramic granules with a particle diameter of 0.01-20 mm;

[0041] Step S3: performing polymer coating layer processing on the screened ceramic granules;

[0042] Step S4: mixing and stirring the ceramic granules with the polymer coating layer and the adhesive;

[0043] Step S5: Pour the mixture of ceramic granules in step S4 into a brick-making mold for molding;

[0044] The polymer coating is one or more of epoxy resin adhesive, acrylic resin adhesive and polyurethane adhesive; the adhesive is one or more of epoxy resin adhesive, acrylic resin adhesive and polyurethane adhesive kin...

Embodiment 3

[0053] (1) Preparation of ceramic granules that meet the particle size

[0054] Collect the ceramic granules, pre-grind the ceramic granules, carry out magnetic separation and sieving, grind and classify, classify the preferred grades according to the particle size, and then activate the ceramic granules through special surface treatment, the surface The treatment can be grinding or using a chemical activator to change the structure and shape of the ceramic granules. The chemical activator can prepare an acidic substance, and use the acidic substance to treat the surface of the ceramic granules to increase the surface area of the ceramic granules.

[0055] (2) Preparation of ceramic granules with polymer coating

[0056] 24g epoxy adhesive (18g is NPEL-127 epoxy resin, epoxy equivalent is 176-184g / eq; 2g is NPPN-431A70 epoxy resin; 4g is T31 curing agent); 0.5 gram light stabilizer GW- 3346, 1 kg of ceramic granules with an average particle diameter of 5 mm obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com