Ionic type cyclometalated iridium complex liquid crystal luminescent material and application thereof in non-doped polarizing red electroluminescent device with single luminescent layer

A technology of iridium complexes and luminescent materials, applied in luminescent materials, liquid crystal materials, electric solid devices, etc., can solve the problem of low luminous efficiency, etc., and achieve the effect of inhibiting luminescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation scheme of cyclometal iridium complex formula 1: the synthetic route of cyclometal iridium complex liquid crystal luminescent material (formula 1) is as follows:

[0032]

[0033] Reactionconditions:(a)Pd(PPh 3 ) 4 ,2MK 2 CO 3 , THF, reflux, overnight. (b) BBr 3 ,CH 2 Cl 2 ,-78℃-roomtemperature,20h.(c)1,2-bis(2-(p-tolyloxy)ethoxy)ethane(or1,6-dibromohexane),K 2 CO 3 ,KI,acetone,reflux,24h.(d)3or4,K 2 CO 3 ,KI,acetone,reflux,24h.(e)LiAlH 4 ,THF,roomtemperature,8h.(f)2,2'-bipyridine-4,4'-dicarbonyldichloride,Et 3 N,CH 2 Cl 2 ,reflux,overnight.(g)(ppy)4 IrCl 2 ,KPF 6 ,MeOH / CH 2 Cl 2 , reflux, overnight.

[0034] Preparation of Compound 1:

[0035] Add 4-ethoxy-2,3-difluorophenylboronic acid (5.0g, 24.8mmol), 1-iodo(4-pentylcyclohexyl)benzene (9.0g, 25.3mmol), Pd (PPh 3 ) 4 (0.25mmol, 0.29g), K 2 CO 3 solution (2M, 15 mL), toluene (45 mL) and ethanol (15 mL), and the mixture was refluxed overnight under argon atmosphere. After the r...

Embodiment 2

[0059] Testing of liquid crystal properties of cyclometalated iridium complex luminescent materials:

[0060] The liquid crystal properties of cyclometalated iridium complexes Ir1 and Ir2 were tested by differential scanning calorimetry (DSC), polarized light microscopy (POM) and X-ray diffraction (XRD). Such as Figure 4 As shown, both Ir1 and Ir2 exhibit multiple phase transition points in the process of heating and cooling; and POM can observe that the iridium complex has fluidity and birefringence in the process of cooling ( Figure 4 ), which indicates that these two iridium complexes have liquid crystal properties. Further, the liquid crystal texture of the iridium complex was confirmed by temperature-changing XRD test. if Figure 6 As shown, at room temperature, Ir2 exhibits strong diffraction peaks at 1.32°, 2.63° and 4.01°, respectively, which is a typical ordered crystal structure. When the temperature is raised to 180°C, there are only weak diffraction peaks at ...

Embodiment 3

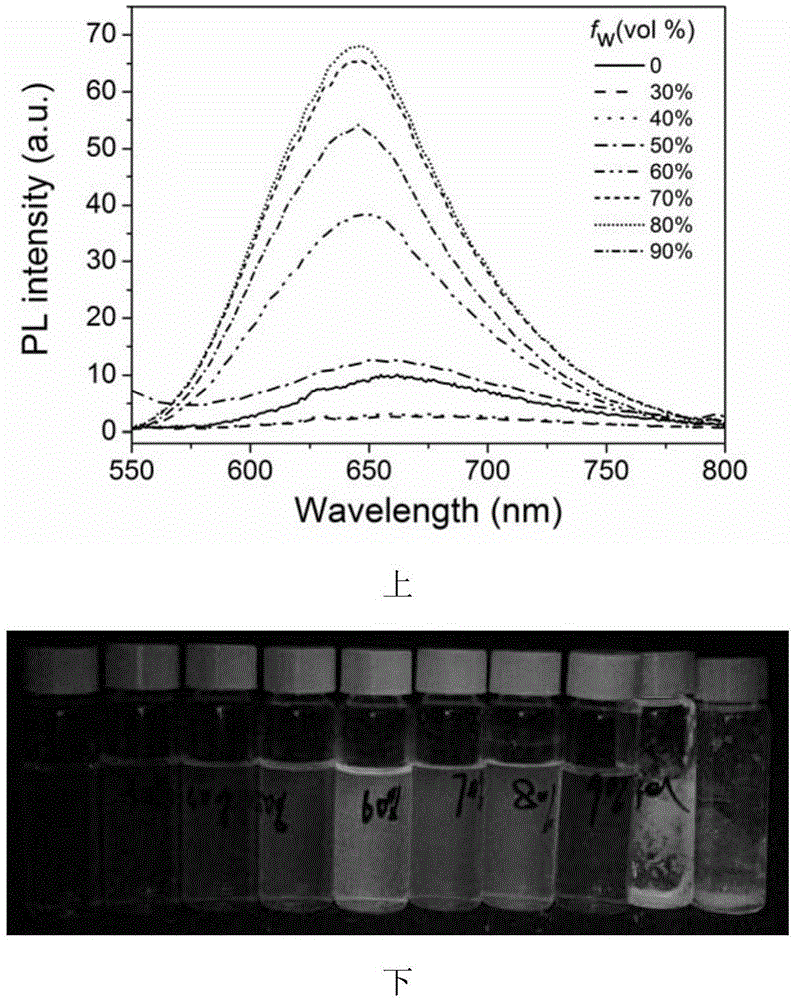

[0062] Test of Aggregation-Induced Emission (AIE) Performance of Cyclometallic Iridium Complex Liquid Crystal Luminescent Material:

[0063] Dissolve the iridium complex Ir1 in THF to prepare a concentration of 10 -4 M solution; take 1mL of the solution and place it in 8 volumetric flasks; add different volumes of water to make the water content 0%, 30%, 40%, 50%, 60%, 70%, 80% and 90% . At room temperature, test the fluorescence spectra of these 8 groups of mixed solutions. Such as image 3 As shown, when the water content gradually increases, the luminescence intensity of the complexes gradually increases, especially the complex Ir1 exhibits a strong red light in the solid state. This shows that this iridium complex has AIE performance and can obtain high-efficiency luminescence in the solid state, which provides a new design idea for improving the luminescence efficiency of liquid crystal light-emitting materials in high concentrations and solid films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com