Fluorine-containing flexible-rigid polyimide film, and preparation method and application thereof

A technology of polyimide film and hard block, which is applied in the field of fluorine-containing soft-hard block polyimide film and its preparation, can solve the problems of low thermal expansion coefficient, high dielectric constant, low dielectric constant, etc. Achieve the effect of low thermal expansion coefficient, large free volume and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

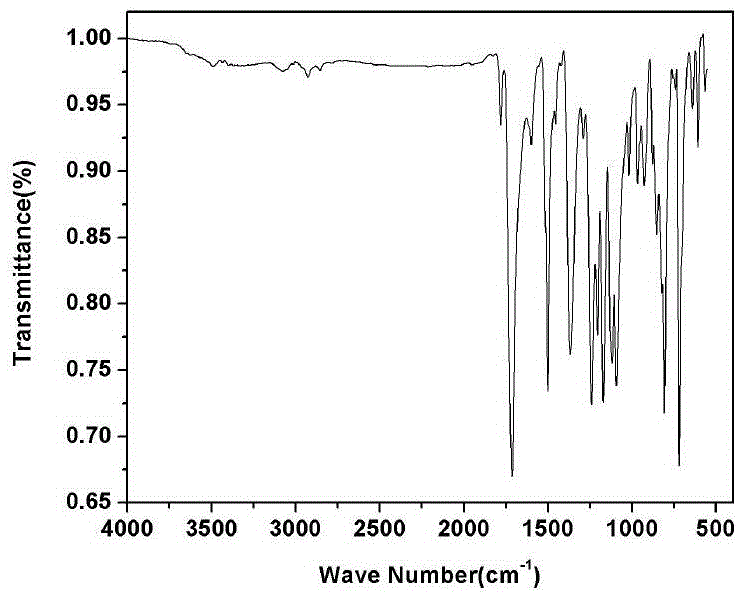

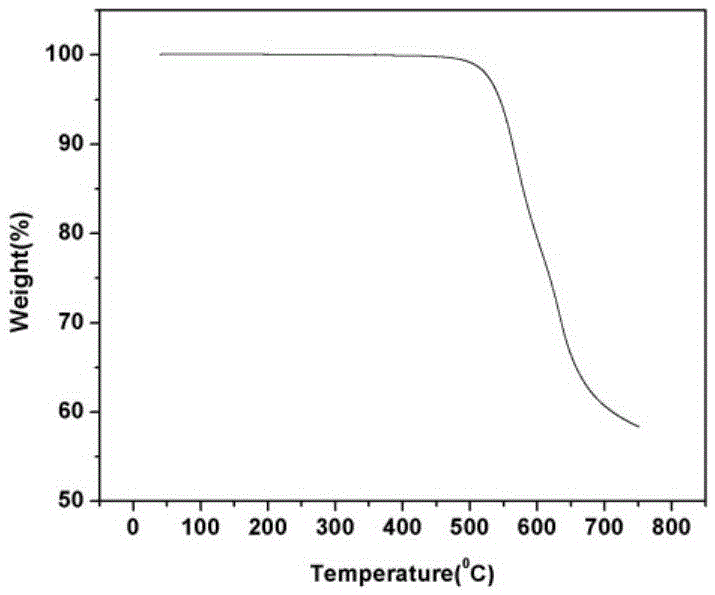

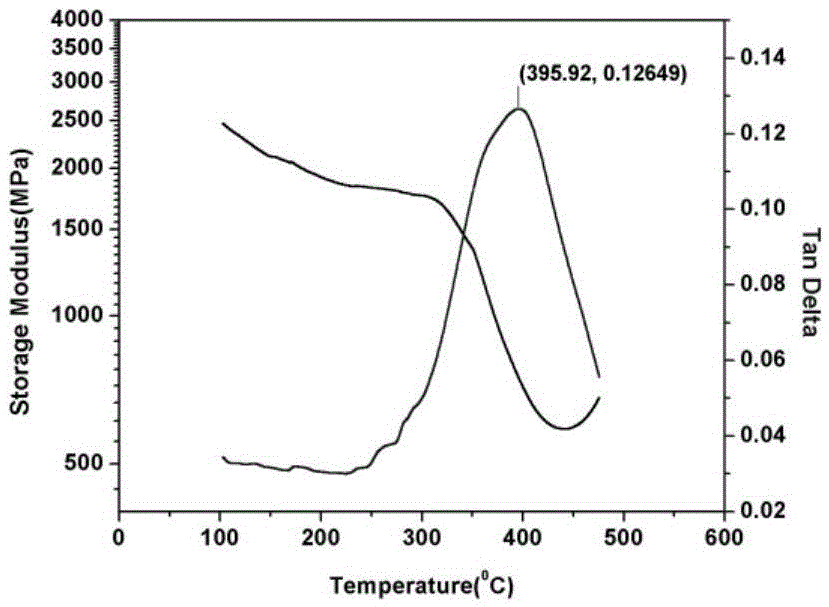

[0079] This embodiment provides a polyimide film, containing flexible fluorine-containing aromatic diamine, aromatic dianhydride-1, rigid aromatic diamine and rigid aromatic dianhydride;

[0080] Wherein the flexible fluorine-containing aromatic diamine is preferably 6FBAPP, the aromatic dianhydride-1 is preferably a mixture of BTDA and PMDA, the rigid aromatic diamine is preferably p-PDA, and the rigid aromatic dianhydride is preferably PMDA;

[0081] Wherein, the molar ratio 6FBAPP:(BTDA+PMDA):p-PDA:PMDA=40:(10+26):60:64.

[0082] The resin preparation method is as follows:

[0083] (1) Weigh 10.37g (0.02mol) of flexible fluorine-containing aromatic diamine 6FBAPP and 63.16g (0.86mol) of organic solvent DMF in a 250ml round-bottomed flask equipped with mechanical stirring and nitrogen inlet and outlet, and stir in a nitrogen atmosphere to form homogeneous solution, then place the flask in an ice-water bath (0°C), add 1.6111g (0.005mol) aromatic dianhydride-1BTDA and 2.8356g...

Embodiment 2

[0097] This embodiment provides a polyimide film, containing flexible fluorine-containing aromatic diamine, aromatic dianhydride-1, rigid aromatic diamine and rigid aromatic dianhydride;

[0098] Wherein the flexible fluorine-containing aromatic diamine is preferably 6FBAPP, the aromatic dianhydride-1 is preferably a mixture of BTDA and PMDA, the rigid aromatic diamine is preferably p-PDA, and the rigid aromatic dianhydride is preferably PMDA;

[0099] Wherein, the molar ratio 6FBAPP:(BTDA+PMDA):p-PDA:PMDA=50:(10+35):50:55.

[0100] The resin preparation method is as follows:

[0101] (1) Weigh 12.9625g (0.025mol) flexible fluorine-containing aromatic diamine 6FBAPP and 349.42g (4.78mol) organic solvent DMF in a 500ml round bottom flask equipped with mechanical stirring and nitrogen inlet and outlet, and stir in a nitrogen protective atmosphere to form homogeneous solution, then put the flask in a low-temperature reaction box (-10°C), add 1.6111g (0.005mol) aromatic dianhydri...

Embodiment 3

[0115] This embodiment provides a polyimide film, containing flexible fluorine-containing aromatic diamine, aromatic dianhydride-1, rigid aromatic diamine and rigid aromatic dianhydride;

[0116] Wherein the flexible fluorine-containing aromatic diamine is preferably 6FBAPP, the aromatic dianhydride-1 is preferably a mixture of BTDA and PMDA, the rigid aromatic diamine is preferably p-PDA, and the rigid aromatic dianhydride is preferably PMDA;

[0117] Wherein, the molar ratio 6FBAPP:(BTDA+PMDA):p-PDA:PMDA=60:(10+44):40:46.

[0118] The resin preparation method is as follows:

[0119] (1) Weigh 15.5550g (0.030mol) flexible fluorine-containing aromatic diamine 6FBAPP and 65.89g (0.90mol) organic solvent DMF in a 250ml round bottom flask equipped with mechanical stirring and nitrogen inlet and outlet, and stir in a nitrogen protective atmosphere to form Homogeneous solution, then place the flask in a constant temperature water bath (30°C), add 1.6111g (0.005mol) aromatic dianhy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com