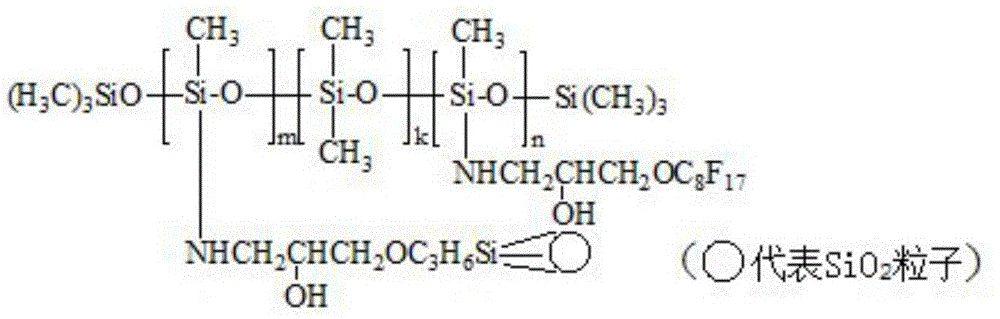

Preparation method for nano SiO2 hybrid comb organic fluorine-silicon copolymer as well as product and application of copolymer

A technology of organic fluorine and copolymer, which is applied in the field of preparation of nano-SiO2 hybrid comb-shaped organic fluorine-silicon copolymer, which can solve the problems of short service life, impervious to washing, easy wear, etc., and achieve simple steps, high hydrophobic angle, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of nano-SiO 2 A method for preparing a hybrid comb-like organic fluorosilicon copolymer, comprising the following steps:

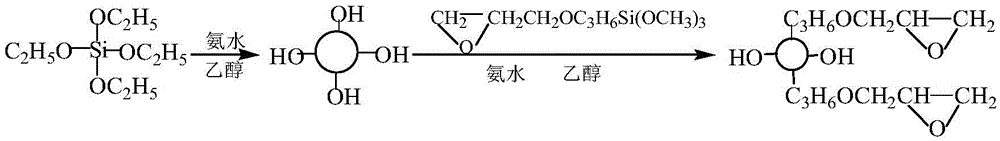

[0027] S1: Epoxy-modified SiO 2 Preparation of:

[0028] (1) Modified SiO 2 Synthesis of the dispersion: add 100g of tetraethyl orthosilicate, 80g of absolute ethanol, and 25g of deionized water into a three-necked flask, stir, heat up to 60°C, add 70ml of ammonia water dropwise, and keep the temperature at 60°C for 4 to 5 hours. Hydrolysis and polycondensation reaction to obtain nano-scale translucent, basic SiO 2 Sol;

[0029] (2) In the above SiO 2 Add 20g of 3-glycidoxypropyltrimethoxysilane to the sol for reflux reaction for 3 to 4 hours, then repeatedly wash, centrifuge, and vacuum dry to obtain a white powdery epoxy-modified SiO 2 ;

[0030] The equation of the S1 step is as follows:

[0031]

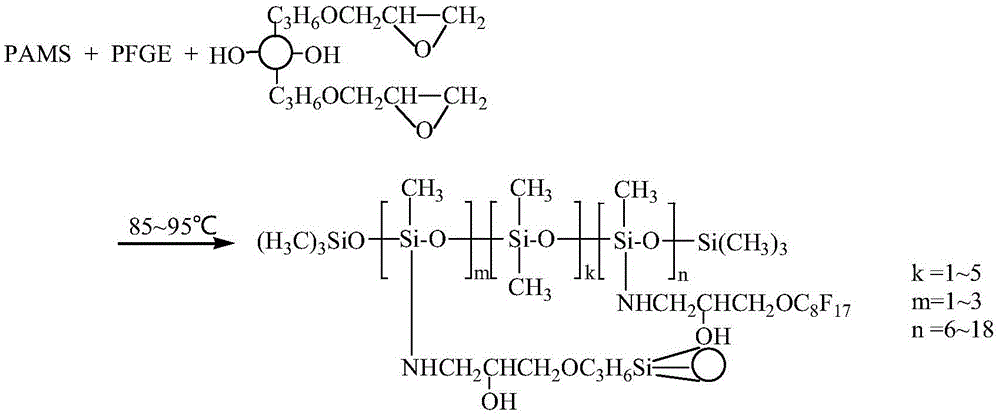

[0032] S2: Nano SiO 2 Preparation of hybrid comb-like organofluorosilicon copolymer:

[0033] (1) In a 250ml three-necked flask eq...

Embodiment 2

[0042] A kind of nano-SiO 2 A method for preparing a hybrid comb-like organic fluorosilicon copolymer, comprising the following steps:

[0043] S1: Epoxy-modified SiO 2 Preparation of:

[0044] (1) Modified SiO 2 Synthesis of the dispersion: add 100g of tetraethyl orthosilicate, 80g of absolute ethanol, and 25g of deionized water into a three-necked flask, stir, heat up to 60°C, add 70ml of ammonia water dropwise, continue to heat up, and keep the temperature at 70°C for 5-6 Hours, through hydrolysis and polycondensation reactions, nano-scale translucent, basic SiO 2 Sol;

[0045] (2) In the above SiO 2 Add 20g of 3-glycidoxypropyltrimethoxysilane to the sol for reflux reaction for 3 to 4 hours, then repeatedly wash, centrifuge, and vacuum dry to obtain a white powdery epoxy-modified SiO 2 ;

[0046] S2: Nano SiO 2 Preparation of hybrid comb-like organofluorosilicon copolymer:

[0047] (1) In a 250ml three-necked flask equipped with a stirrer, a thermometer and a refl...

Embodiment 3

[0053] A kind of nano-SiO 2 A method for preparing a hybrid comb-like organic fluorosilicon copolymer, comprising the following steps:

[0054] S1: Epoxy-modified SiO 2 Preparation of:

[0055] (1) Modified SiO 2 Synthesis of the dispersion: add 100g of tetraethyl orthosilicate, 80g of absolute ethanol, and 25g of deionized water into a three-necked flask, stir, heat up to 60°C, add 70ml of ammonia water dropwise, keep the temperature at 60°C for 4 to 6 hours, and After hydrolysis and polycondensation reactions, nano-scale translucent, basic SiO 2 Sol;

[0056] (2) In the above SiO 2 Add 20g of 3-glycidoxypropyltrimethoxysilane to the sol for reflux reaction for 3 to 4 hours, then repeatedly wash, centrifuge, and vacuum dry to obtain a white powdery epoxy-modified SiO 2 ;

[0057] S2: Nano SiO 2 Preparation of hybrid comb-like organofluorosilicon copolymer:

[0058] (1) In a 250ml three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com